1. Introduction

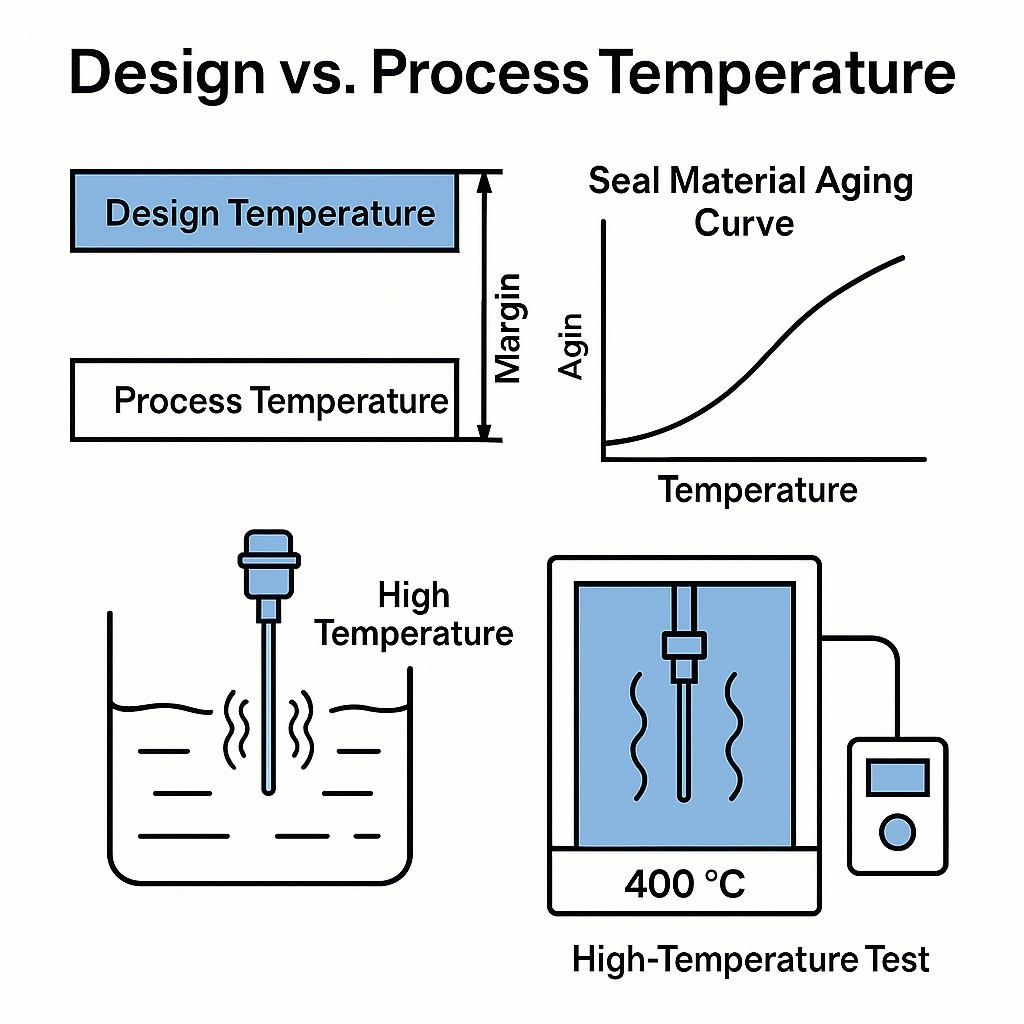

In industrial equipment selection and procurement, design temperature and process temperature are two concepts often confused.

A common question from end users is:

“Our process temperature never exceeds 80 °C. Why is the quotation based on 210 °C high-temperature design?”

At first glance, this seems like over-engineering. However, the distinction between the two parameters is crucial, as it relates to engineering design principles, material science, equipment reliability, and industrial safety.

2. Key Differences

2.1 Design Temperature

Design temperature is the maximum (or minimum) temperature of the process medium specified during equipment design.

It is not merely a theoretical value but a fundamental safety basis for engineering design.

Typical features:

Always higher than normal process temperature, with a safety margin.

Ensures the equipment remains reliable under abnormal or extreme conditions.

Directly influences:

Material selection (strength, elasticity, corrosion resistance).

Sealing and connections (performance of gaskets and joints).

Mechanical design (wall thickness, flange rating, stress calculation).

Electronics and sensors (circuit stability under elevated temperature).

👉 Design temperature = baseline for safe operation throughout the equipment lifecycle.

2.2 Process Temperature

Process temperature is the actual operating temperature of the medium under normal conditions.

It is an operational parameter for monitoring and control, but not sufficient for structural design.

Process temperature may fluctuate due to:

Start-up/shutdown thermal shocks.

Cleaning or sterilization with hot steam.

Heat-exchanger or valve failures introducing high-temperature media.

👉 Relying only on process temperature may expose equipment to seal failure, probe deformation, sensor drift, or electronics damage when unexpected peaks occur.

3. Typical Specification Example

| Parameter | Normal Operating (Process) | Design Basis (with Margin) |

|---|---|---|

| Pressure: 6 bar(g) | 80 °C | 210 °C |

| Pressure: 0.03 bar(g) | 100 °C | 110 °C |

| Pressure: 0.14 bar(g) | 60 °C | 80 °C |

4. Impact of High Temperature on Equipment

Taking a fork-type level switch as an example:

Even if the plant temperature is only 80 °C, high-temperature design is still necessary.

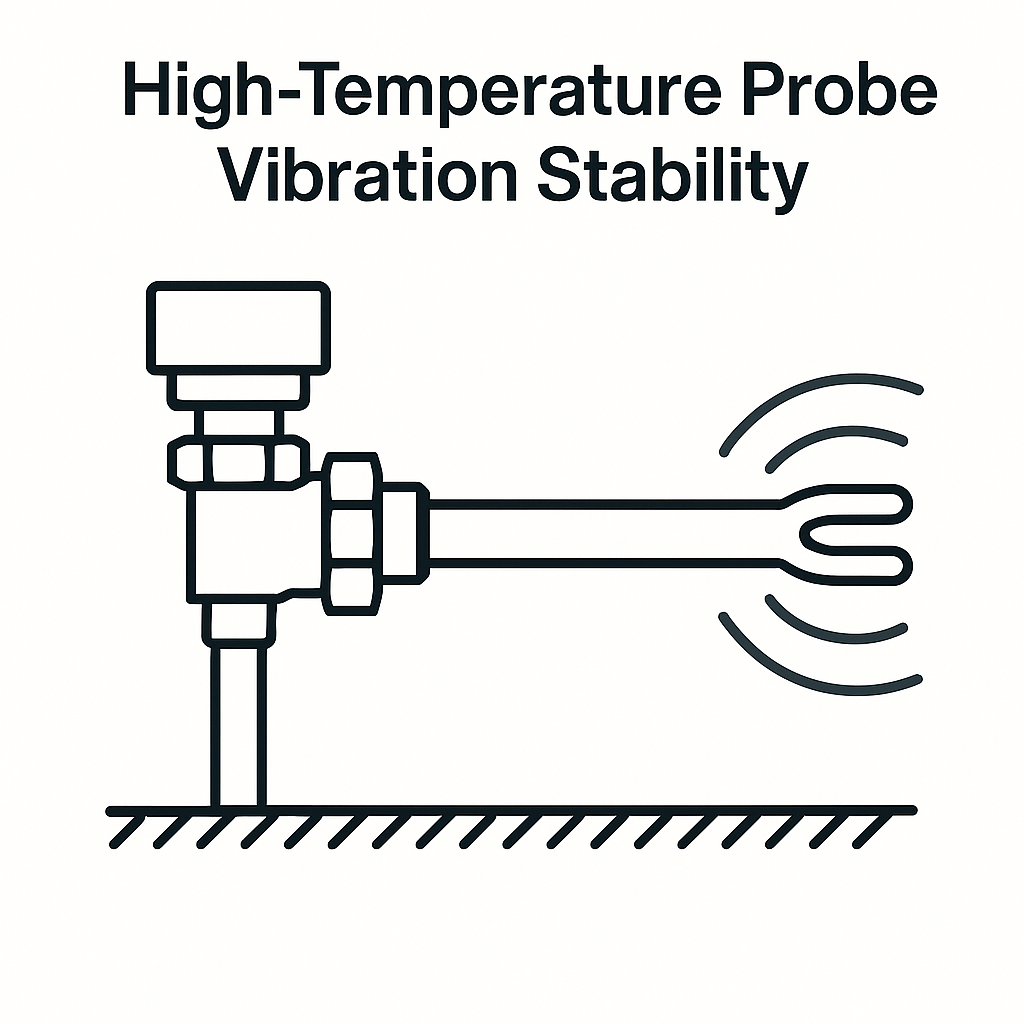

Probe Vibration Characteristics

Elevated temperature changes elasticity modulus and resonance frequency → accuracy may be compromised.

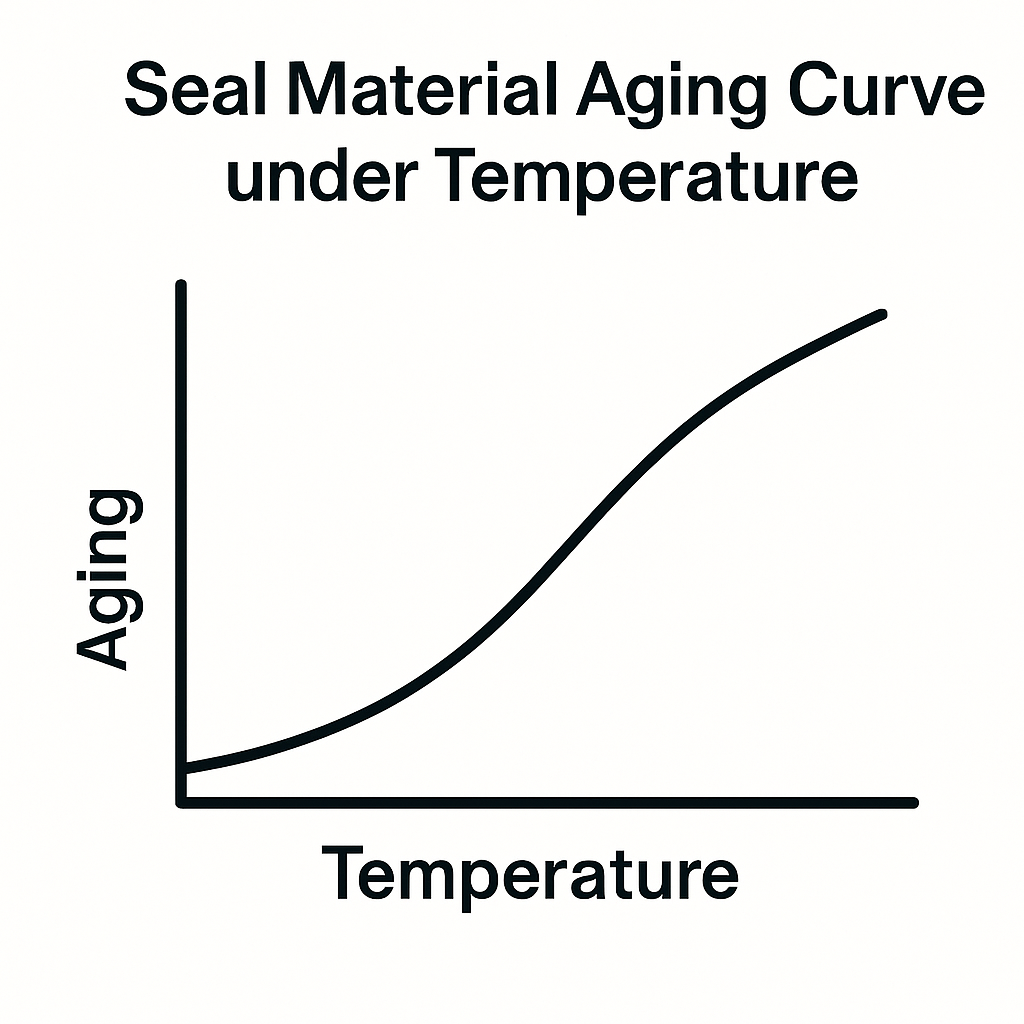

→ High-temperature design ensures stable vibration and reliable detection.Seal Aging and Failure Risk

Heat accelerates gasket aging, leading to leakage.

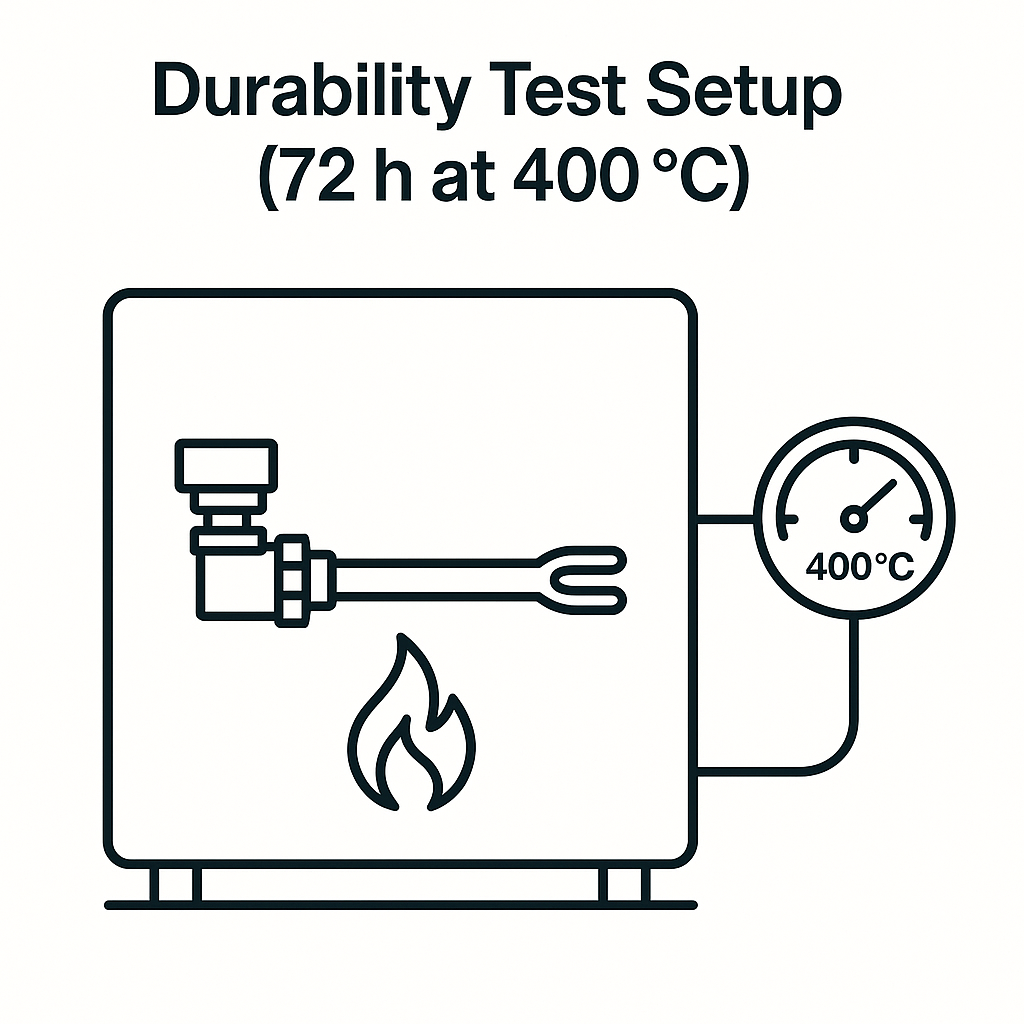

→ Design temperature determines correct material choice and structural integrity.Electronic Component Stability

Excessive temperature causes circuit drift or permanent failure.

→ Proper thermal design (heat-resistant components, insulation, heat dissipation) ensures long-term stability.(Example: Certain high-temperature switches withstand up to 400 °C for 72 h in continuous durability tests.)

Long-Term Reliability

High-temperature design extends service life, reduces maintenance, and prevents unplanned shutdowns.

5. Supplier Responsibility and Recommendations

Always quote based on design temperature, not just process temperature.

State clearly in proposals: design temperature, design pressure, and applicable standards.

If the client only provides process data → request P&ID or process design documents to confirm.

Offer alternative design options with different temperature ratings for cost–safety comparison.

6. Conclusion

Although the observed maximum process temperature may only reach 80 °C, the design temperature is the fundamental safety reference for industrial equipment selection.

One correct decision at procurement stage avoids years of downtime, retrofits, or safety incidents.

One wrong cost-saving decision may result in catastrophic equipment failure during an abnormal event.

👉 Rule of thumb:

Process temperature is for monitoring.

Design temperature is for survival.