In the era of industrial automation, where systems are becoming larger and more intelligent, the I/O modules in Distributed Control Systems (DCS) — which act as the “nervous system” linking the field to the control center — are facing unprecedented challenges. The expansion of plant size leads to a dramatic increase in signal points, while the push for intelligent systems requires the integration of various types of signals. Simultaneously, the compression of project timelines demands parallel design and construction processes. The traditional “single-function I/O modules” model, with its “channel-binding and centralized deployment” approach, is increasingly becoming a bottleneck in project delivery.

In response, leading DCS suppliers have introduced remote general-purpose I/O systems. But can this innovation break the limitations of traditional I/O systems and achieve multiple goals of “cost reduction, speed improvement, and space saving”? This article delves into the value logic of remote general-purpose I/O technology, specifically within petrochemical and other process industries, by exploring its technical principles, core differences, and key enabling technologies.

PART 01: The Growing Pains of Conventional DCS I/O

The Dilemma of Conventional DCS I/O: From “Sufficient” to “Difficult to Use”

Conventional DCS I/O modules are designed with a key characteristic: “single-function channels, centralized deployment.” Each I/O channel supports only one type of signal (e.g., 4-20mA analog input or discrete output), and all modules are concentrated in the control room. This approach works well in smaller plants but becomes increasingly inefficient in complex environments like large petrochemical facilities:

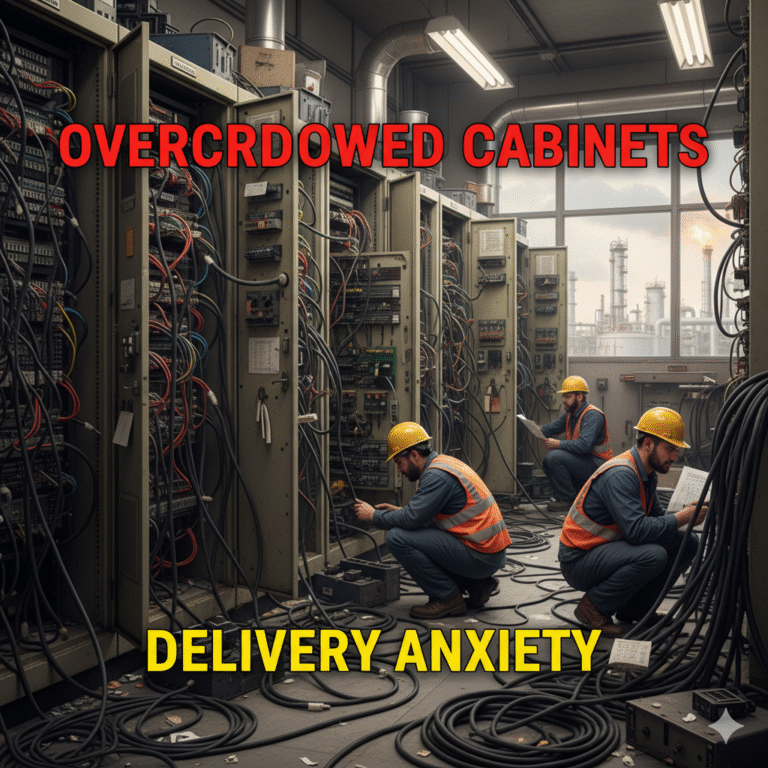

Overcrowded Cabinets and Increased Space Usage

Large petrochemical plants have a wide variety of signal types (analog, digital, HART, pulse, etc.). Each signal requires its own I/O module. As the number of signals grows from thousands to tens of thousands, the number of single-function I/O modules multiplies, along with the supporting terminal and system cabinets. As a result, the size of the control room increases significantly. For instance, in a 10 million-ton refinery project, the conventional I/O system’s cabinet area can exceed 800 square meters, significantly driving up construction costs.Redundant Cabling and Complicated Installation

To connect field instruments to the control room, cables are categorized by signal type and routed to the corresponding terminal and I/O modules. With tens of thousands of signals, this requires hundreds of thousands of meters of cable, driving up procurement costs and complicating installation. During later maintenance, cross-wiring and troubleshooting become more challenging and time-consuming.Inflexible Design and Extended Timelines

Before DCS procurement, it is essential to accurately count the number of signals to determine the I/O module models and cabinet sizes. Any changes in signal types or quantities during later stages of the project require redesigns and module replacements, resulting in longer design periods and delayed project delivery.

PART 02: Breaking the Mold: The Technological Breakthrough of General-Purpose I/O

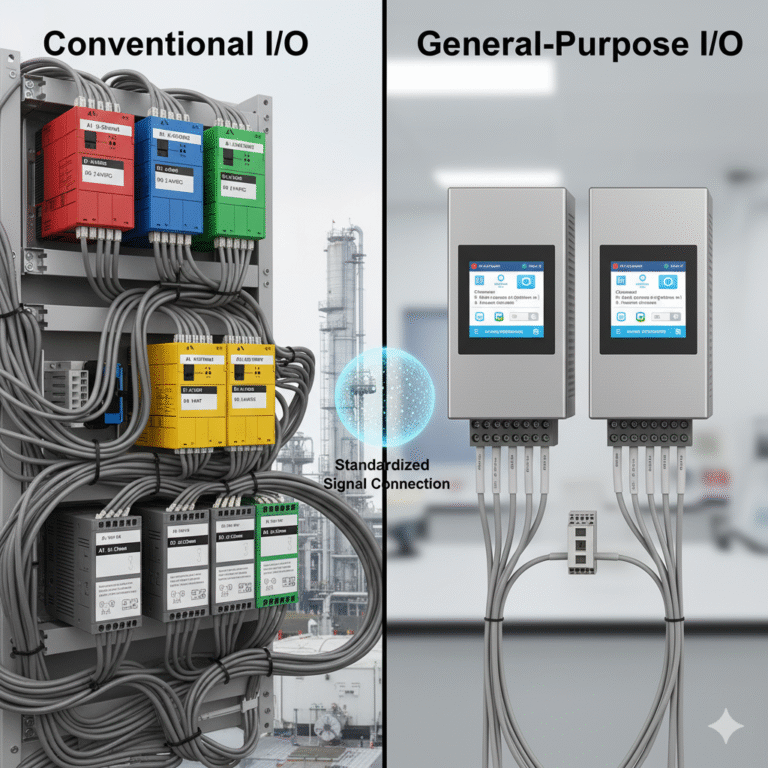

The core breakthrough of general-purpose I/O modules lies in their ability to “software-define channels and standardize signal connections,” fundamentally breaking the “one module per signal type” constraint. This innovation addresses the challenges of conventional I/O systems and becomes the core technology supporting the solution.

Key Advantages: Universal Channel Compatibility and Lightweight Deployment

Channel Software Configuration

Each I/O channel can independently configure the signal type via software (e.g., 4-20mA input/output, discrete input/output, HART signals, etc.). Different signal types can be routed into the same module, eliminating the need for separate wiring for each signal type. This greatly reduces the number of I/O module types and cuts cabinet size by 30-50%. The design process becomes much simpler, as there is no need to precisely count each signal type — just allocate a few spare channels to accommodate any signal changes during the project.Three Key Technologies Supporting General-Purpose Capabilities

Signal Integrity Technology: The modules are equipped with circuits capable of processing various signal types, from low-level analog signals to high-frequency pulses, without needing additional signal converters. This ensures compatibility and precision.

High-Speed Signal Acquisition: Using high-speed A/D and D/A conversion chips and digital signal processing algorithms, these modules can collect signals at microsecond speeds, even when different signal types are mixed. This meets the real-time demands of industries like petrochemicals, where quick responses are crucial.

Online Channel Type Switching: The software allows users to switch signal types without powering down the system, making the I/O system adaptable to temporary changes during production.

PART 03: Practical Deployment Conditions: From Centralized Control to Remote Distributed Systems

The full potential of general-purpose I/O systems can be realized through “remote distributed deployment” — placing the I/O modules and accessories into “remote I/O junction boxes” near the field instruments and connecting them to the control room via optical fiber digital bus. This approach significantly reduces cable lengths (by 60-80%), but it also introduces challenges that must be overcome in petrochemical environments, such as:

Explosion-Proof Technology: Adapting to Hazardous Areas

Petrochemical plants often operate in explosive environments, requiring I/O junction boxes to meet stringent explosion-proof standards (e.g., GB/T 3836.1-2021). These boxes must undergo CCC certification and be able to withstand explosive gas conditions (Zone 0, 1, or 2) in hazardous areas.Redundant Communication Technology: Ensuring Stable Data Transmission

To maintain high reliability and low latency, the remote I/O junction boxes use dual optical fiber redundancy to ensure automatic switching to backup lines in case of failure. The communication should also be resistant to electromagnetic interference, using protocols such as Profinet or Modbus TCP to meet the demands of the harsh petrochemical environment.Adaptability to Harsh Environments

The remote I/O boxes are often installed outdoors and must withstand extreme conditions such as high temperatures, humidity, salt mist, sand, and storms. Solutions include heat dissipation optimization, corrosion-resistant coatings, and lightning protection modules to safeguard the equipment.

PART 04: Comparison of Advantages: Remote General-Purpose I/O vs. Conventional I/O

Full Comparison Chart:

[Include a side-by-side comparison chart highlighting key metrics such as cost reduction, space saving, flexibility in design, and installation efficiency.]

PART 05: Conclusion: A Technological Upgrade and Engineering Revolution

Remote general-purpose I/O technology is not just a “technical upgrade”; it is a revolutionary shift in engineering practices. By combining “software-defined channels” with “distributed deployment,” it restructures the design, construction, and operation logic of DCS I/O systems. This innovation allows for parallel design and construction, reducing project timelines significantly. It also cuts costs associated with cabinets, cables, and construction, while simplifying long-term maintenance. For process industries like petrochemicals, this technology is a critical solution for adapting to the demands of large-scale, intelligent systems, while also promoting a shift from “inefficient construction” to “lean management” in industrial control engineering.

As technologies like explosion-proof and redundant communication continue to evolve, this solution will become the standard for DCS systems in large industrial facilities.