Introduction

With the continuous advancement of industrial automation technology, Distributed Control Systems (DCS) have become the preferred control platform for many complex and continuous production processes. One of the most critical steps in implementing a DCS is configuration, which directly impacts the system’s stability and reliability. DCS configuration, in simple terms, refers to setting up and designing a system that efficiently controls industrial processes through parameter configurations and logic design. This process is more than just “software programming”—it utilizes graphical and modular approaches to map complex industrial processes into an automated management system, optimizing efficiency and precision.

Understanding DCS Configuration and Its Importance

DCS configuration is fundamentally a graphical configuration process, but it extends beyond traditional programming. It involves connecting, defining, and setting up various signals and functions between field devices and the control system, ensuring precise and efficient automation of the production process.

Why is DCS Configuration Important?

Modular Design: Breaks down complex control tasks into manageable and operable units, enhancing system reliability, flexibility, and scalability.

Real-Time Monitoring and Control: Enables precise, real-time monitoring and control for industries such as chemical processing, power generation, and steel manufacturing.

Enhanced Safety and Efficiency: Ensures optimized process control, reducing downtime and increasing operational efficiency.

Seamless Integration: Facilitates the integration of various control functions, data acquisition, alarm processing, and historical trend tracking.

Key Features and Advantages of DCS Configuration

DCS configuration offers distinct advantages, differentiating it from traditional Programmable Logic Controllers (PLC) and Supervisory Control and Data Acquisition (SCADA) systems.

High Reliability: DCS systems often include redundancy mechanisms to prevent production stoppages caused by single-point failures.

Real-Time Response: Millisecond-level update speeds ensure precise sensor data processing and feedback.

Support for Complex Algorithms: Enables configurations such as PID control, cascade control, and advanced optimization techniques.

Graphical User Interface (GUI): Intuitive Human-Machine Interfaces (HMI) allow operators to monitor and control processes effectively.

Distributed Architecture: Unlike centralized PLCs, DCS distributes control tasks across intelligent nodes, improving reliability and fault tolerance.

Comparing DCS, PLC, and SCADA

To understand where DCS excels, let’s compare it with PLC and SCADA systems:

| System | Best Use Cases | Key Features |

|---|---|---|

| DCS | Large-scale continuous process industries (e.g., chemical plants, power plants) | High reliability, real-time process control, redundant system design |

| PLC | Discrete manufacturing (e.g., automotive assembly lines) | Fast execution speed, high flexibility, cost-effective for small applications |

| SCADA | Remote monitoring and supervisory control | Data acquisition, centralized control, wide geographic distribution |

General Steps of DCS Configuration

Though DCS configuration might seem complex, it follows a structured process to ensure efficiency and accuracy.

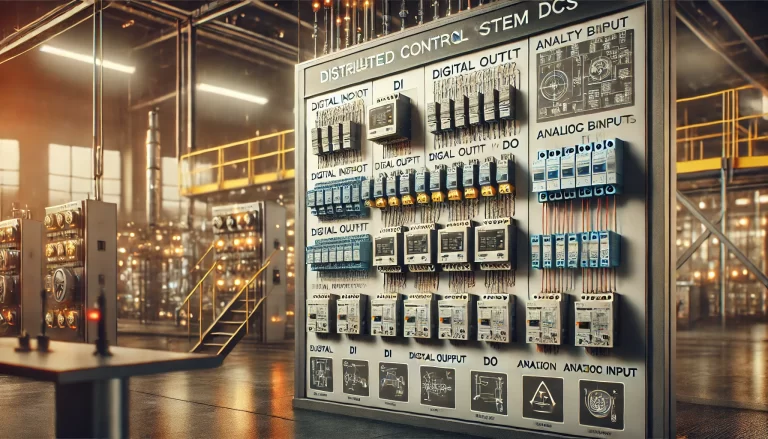

1. Defining I/O Signals

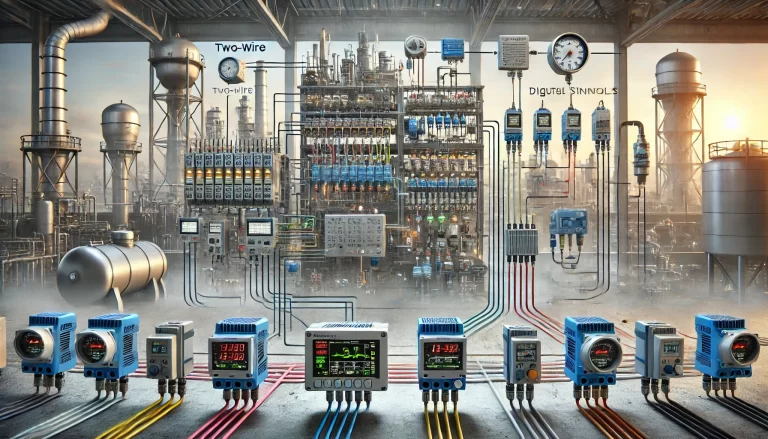

The first step in DCS configuration is defining Input/Output (I/O) signals. Proper signal configuration ensures that field devices (such as sensors and actuators) communicate correctly with the control system.

Assign I/O signals to the DCS I/O modules based on real-world plant layouts.

Convert sensor outputs (e.g., 4-20mA signals) into meaningful physical quantities such as temperature, flow rate, or pressure.

2. Designing Control Logic

This is the core of DCS configuration. Engineers define how different parts of the system interact by configuring control loops and logic.

PID Controllers: Used for regulating temperature, pressure, and flow rates.

Interlocking Mechanisms: Ensure safe operation by preventing undesired actions.

Sequential Control: Manages step-by-step processes, such as startup and shutdown sequences.

Custom Algorithms: For specialized process optimization and decision-making.

3. Developing HMI (Human-Machine Interface) Screens

The HMI allows operators to monitor and control the system effectively.

Create process flow diagrams that visually represent production processes.

Implement alarms, trends, and data visualization tools for real-time insights.

Design interactive controls for user-friendly operation.

4. Configuring Alarms and Trend Monitoring

Proper alarm settings and trend monitoring enhance system safety and efficiency.

Alarm Management: Alerts operators to abnormal conditions (e.g., temperature exceeding a threshold).

Historical Trend Analysis: Tracks process parameters over time to identify inefficiencies or failures.

5. Downloading and Commissioning the Configuration

Once the configuration is completed, it needs to be downloaded to the DCS controllers for execution.

Testing & Debugging: Engineers simulate process conditions to validate configurations.

Calibration & Optimization: Ensures precise operation in a real-world environment.

Operator Training: Provides instructions on system interaction and troubleshooting.

Case Study: DCS Configuration in a Chemical Plant

A chemical manufacturing facility implemented a DCS system to optimize its reaction process control.

Problem: The existing PLC-based control system led to frequent fluctuations in reaction temperature, affecting product quality.

Solution: Engineers reconfigured the system using a DCS approach, implementing a cascade PID control strategy to regulate reactor temperatures more precisely.

Results:

Temperature fluctuations reduced by 30%.

Product yield increased by 15% due to improved process stability.

Real-time alarms and trend monitoring improved plant safety and operator efficiency.

This example highlights how DCS configuration plays a crucial role in achieving optimal industrial automation performance.

Future Trends in DCS Configuration

As automation continues to evolve, the future of DCS configuration will integrate with advanced technologies:

AI and Machine Learning: Predictive maintenance and process optimization using AI algorithms.

Cloud Integration: Remote monitoring and data analysis through cloud-based platforms.

IoT Connectivity: Real-time communication with smart sensors and devices.

Cybersecurity Enhancements: Improved protection against cyber threats in industrial environments.

User-Friendly Interfaces: More intuitive, drag-and-drop configuration tools for engineers.

Conclusion

DCS configuration is a crucial aspect of industrial automation, enabling precise and efficient process control across multiple industries. By following a structured approach—from defining I/O signals and designing control logic to developing HMI screens and testing configurations—engineers can optimize operations for enhanced productivity and safety.

As technology advances, DCS systems will continue to evolve, incorporating AI, IoT, and cloud-based solutions to further streamline industrial control processes. By leveraging these innovations, industries can achieve greater efficiency, reliability, and intelligence in their automation systems.