Introduction:

A common issue in flow measurement systems is the occurrence of small readings even when no flow is present. This phenomenon, caused by zero drift in the meter, can lead to inaccurate data, false alarms, and interference with control systems. The small signal cut-off feature is designed to address this issue by eliminating these false readings. However, if misapplied, it can introduce new problems. This article explains how to properly apply the small signal cut-off functionality in flow converters and secondary tables.

Purpose of Small Signal Cut-off:

Small signal cut-off is implemented to eliminate the false readings caused by zero drift. It is essential to ensure that the flow measurement system does not display readings in the absence of actual flow. When correctly configured, this feature improves data accuracy and prevents erroneous alarms. However, incorrect configuration can lead to new problems, such as unnecessary signal cuts or missed readings.

Application in Systems Without Secondary Tables:

In systems where the flow meter does not have a secondary table, or where the flow measurement results and diagnostic information are transmitted via a digital communication port to a computer, small signal cut-off can be configured directly within the flow converter. This setup is sufficient to eliminate false readings in the absence of flow.

Application in Systems With Secondary Tables:

For systems that include secondary tables, there are two potential configurations:

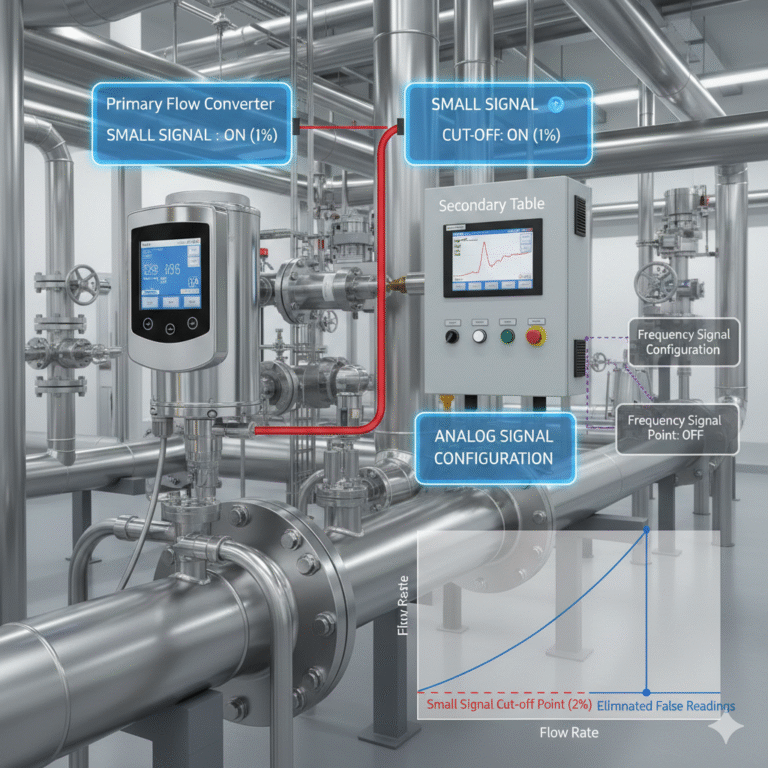

Analog Signal Configuration:

In this case, the flow converter sends measurement results to the secondary table via an analog signal. If the secondary table lacks small signal cut-off, it is possible for the flow reading to still display a value other than zero due to drift introduced during signal conversion. To avoid this, both the flow converter and secondary table should have small signal cut-off settings. Furthermore, the cut-off value in the secondary table should not exceed that of the flow converter.Frequency Signal Configuration:

For systems where the flow measurement is transmitted via frequency signals, the entire process is based on digital signal processing. Since there is no risk of zero drift with digital signals, the secondary table typically does not require a small signal cut-off setting.

Flow Meter Types and Small Signal Cut-off:

In the measurement of parameters such as temperature, pressure, flow, and liquid level, only flow meters require small signal cut-off due to their unique challenges. The purpose of this feature is to address the “false zero” issue. The application of small signal cut-off varies significantly depending on the type of flow meter in use.

Differential Pressure Flow Meters:

Differential pressure flow meters are among the most widely used and historically significant types. Early differential pressure meters lacked the capability to implement small signal cut-off, relying instead on manual zero-point calibration to correct drift. With the introduction of electronic technology and advanced analog and logic circuits, small signal cut-off was integrated into these systems, making them much more accurate.The relationship between flow and differential pressure is typically nonlinear, with the slope of the curve becoming very steep as flow approaches zero. This steep slope causes significant instability in the zero-point reading, leading to large discrepancies in flow measurement. Historically, the accuracy of differential pressure meters was rated at 1.5%, meaning drift of up to ±1.5% was acceptable, leading to discrepancies in low flow measurements.

As technology improved, differential pressure transmitters became more accurate, with manufacturers recommending small signal cut-off points at 1% of the maximum differential pressure. Further advancements have led to more precise transmitters, reducing the need for larger cut-off values. Modern systems can achieve a cut-off point as low as 2% of the maximum flow rate without compromising system stability.

Why Lowering the Small Signal Cut-off Point Matters:

Reducing the small signal cut-off point is crucial as it minimizes the occurrence of false readings at low flow levels. However, lowering the cut-off point too much can cause the system to display zero flow even when there is a small but significant measurement, which could frustrate users. Therefore, balancing between eliminating false readings and ensuring accurate low-flow measurements is key.

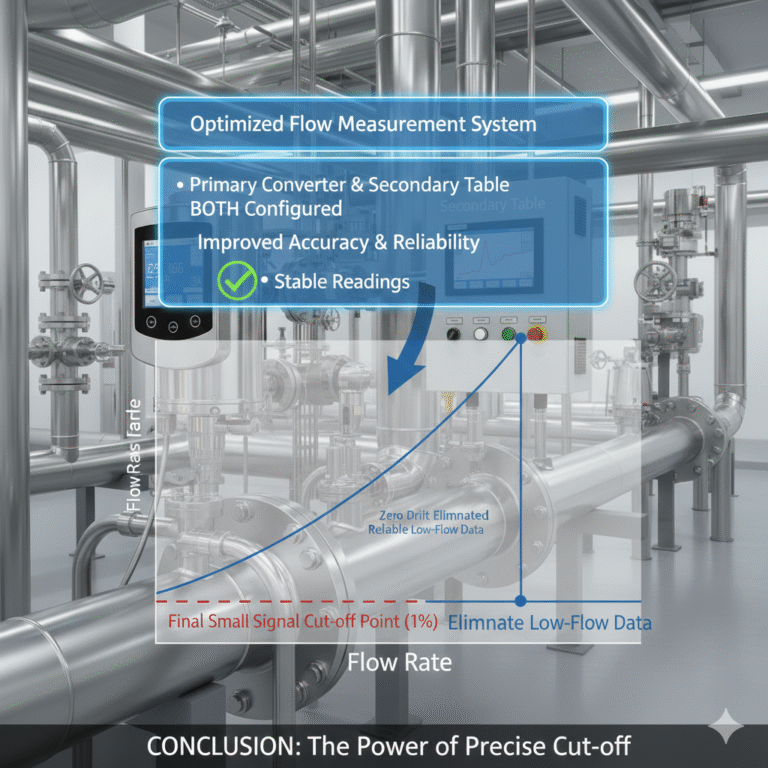

Conclusion:

Small signal cut-off is a valuable tool in flow measurement systems, particularly for eliminating the issue of zero drift and false readings. However, careful attention must be paid when applying this feature, especially in systems with secondary tables. Both the flow converter and secondary table must be properly configured to ensure that small signal cut-off is applied without introducing new problems. With advancements in technology, it is now possible to set very low cut-off points, resulting in more reliable and accurate flow measurements across a wide range of conditions.