Introduction

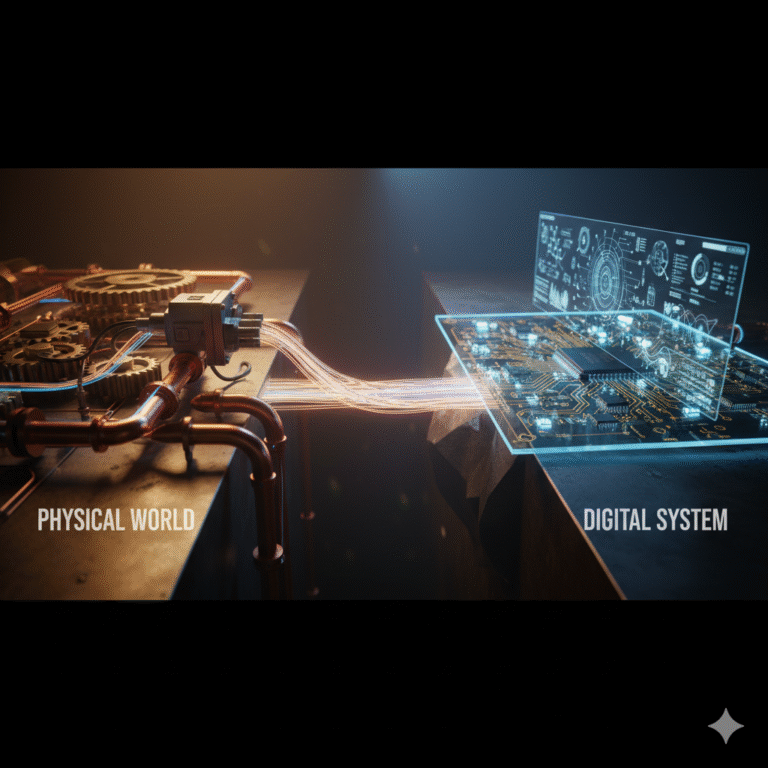

In industrial automation, smart devices, and measurement & control systems, sensors serve as the key bridge connecting the “physical world” with the “digital system.” As the critical component interacting directly with the object being measured, the sensor’s performance determines the accuracy of subsequent signal processing and control decisions.

Definition, Role, and Core Concept

Definition of a Sensor

A sensor is a device or instrument that detects changes in measured parameters and converts them into physical signals that can be transmitted and processed, according to specific rules and accuracy. In different fields, it may also be referred to as a transducer, detector, or probe, but its core function remains the same: converting the “measured quantity” into a usable signal.

In the context of automatic control systems, if the computer is considered the “brain,” the sensor functions as the “senses.” It is responsible for detecting various measured quantities, such as temperature, pressure, flow, and chemical concentration, and is an indispensable “front-end perception unit” in automatic detection and control systems. As automation levels increase, the system’s requirements for sensor sensitivity, stability, and accuracy become more stringent.

Core Functions and Output Formats of Sensors

The core value of sensors lies in “signal conversion and information acquisition”:

Input: Covers physical quantities (such as temperature, pressure, displacement), chemical quantities (such as gas concentration, pH values), and biological quantities (such as humidity, microbial concentration).

Output: Primarily electrical signals (e.g., voltage, current, frequency, pulses), but it may also include gas or optical signals. However, electrical signals are the most common due to their ease of transmission and processing.

Application: The sensor serves as the only link connecting the “measured object” with the “control system,” meeting the needs of information transmission, processing, recording, display, and control.

The Four Core Meanings of the Sensor Concept

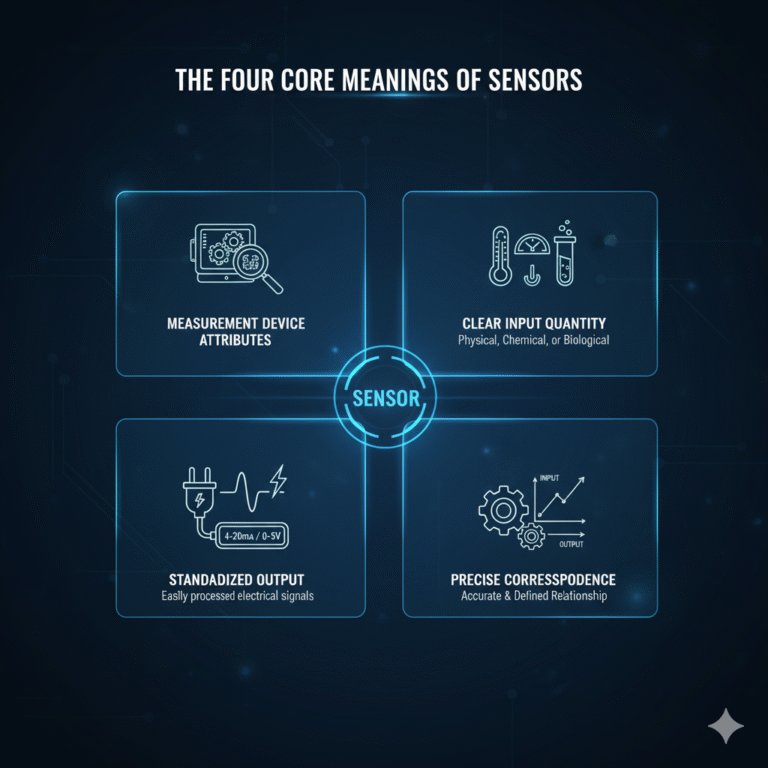

The definition of a sensor must focus on the following four key dimensions:

Measurement Device Attributes: Essentially, it is a specialized device for information acquisition, not merely a “component.”

Clear Input Quantity: The input must be a specific “measured quantity” (physical, chemical, or biological), with a defined purpose.

Standardized Output: The output must be easily processed and transmitted, with electrical quantities being the most common.

Precise Correspondence: The output must correspond accurately to the input, with a defined functional relationship and required precision—this is the distinguishing feature of sensors compared to ordinary “sensing elements.”

Components

Three-Part Architecture and Structural Flexibility

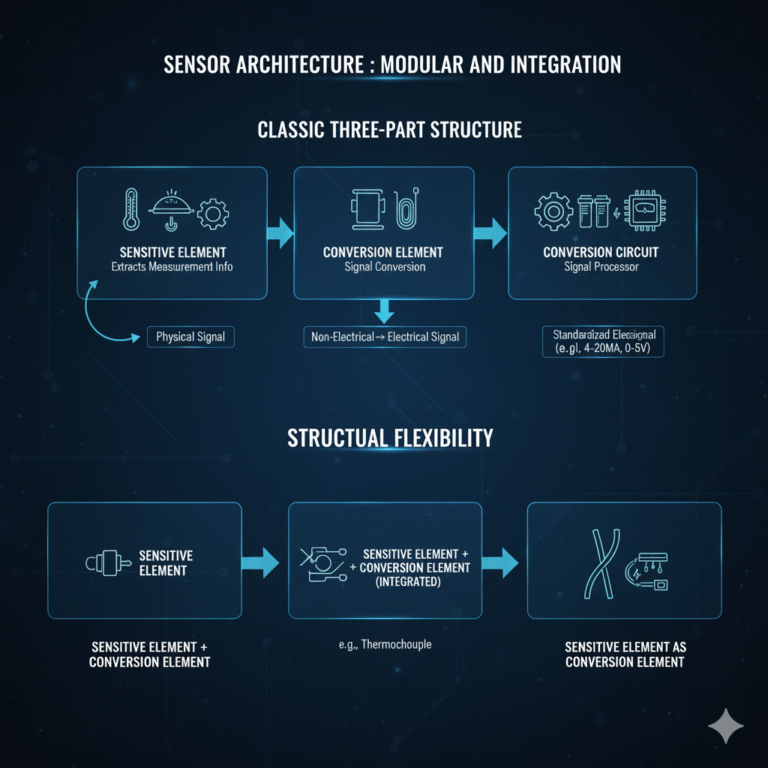

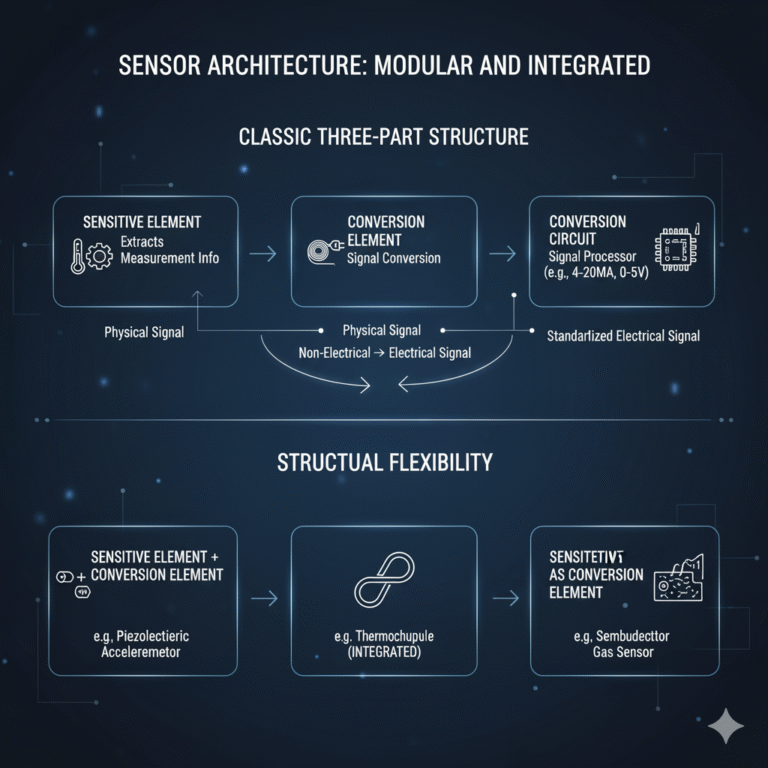

The classic sensor model consists of three components: “sensitive element,” “conversion element,” and “conversion circuit.” However, the actual structure may vary significantly depending on the sensor’s principle and purpose. Not all sensors contain all three components.

Classic Three-Part Structure and Functions

Sensitive Element (“Direct Sensor”): This part directly contacts the measured object, detects changes in the measured quantity, and outputs the corresponding physical signal. Its main task is to “extract the measurement information.” The output is typically a non-electrical physical quantity (e.g., displacement, force, or temperature change). For example, a thermometer’s “sensing bulb” detects temperature changes and causes expansion, and a pressure sensor’s “elastic diaphragm” detects pressure changes and undergoes deformation.

Conversion Element (“Signal Converter”): The conversion element converts the non-electrical signal from the sensitive element into an electrical signal suitable for transmission and measurement. It is the key link between “non-electrical signals” and “electrical signals,” performing the “signal conversion.” For example, in a pressure sensor, the deformation of the “elastic diaphragm” (sensitive element) is converted into a “resistance change signal” by a “strain gauge” (conversion element).

Conversion Circuit (“Signal Processor”): The conversion circuit processes the raw electrical signals from the conversion element (such as small variations in resistance, charge, or voltage) into standard, stable, and usable electrical quantities (such as 4-20mA current or 0-5V voltage). Common conversion circuits include bridge circuits, amplification circuits, filtering circuits, and modulation-demodulation circuits. For example, a “charge amplifier” in a piezoelectric sensor converts the weak charge output from the piezoelectric element into a stable voltage signal.

2. Flexibility of Sensor Structure

Not all sensors adhere strictly to the three-part structure. Based on the sensor’s principle and accuracy requirements, the components may be integrated or simplified:

Sensitive Element + Conversion Element (without a conversion circuit): Some sensors do not require a separate conversion circuit, and the signal from the conversion element can be directly transmitted. For instance, in a piezoelectric accelerometer, the “mass” (sensitive element) detects acceleration and generates an inertial force, which is directly converted into an electrical charge by the “piezoelectric element” (conversion element).

Sensitive Element + Conversion Element + Conversion Circuit (integrated): Some sensors combine all three components into one, making it difficult to distinguish them. For example, a thermocouple’s metal wire acts as both the “sensitive element” (detecting temperature changes) and the “conversion element” (converting temperature differences into thermoelectric potential), with the output directly fed into the measurement circuit.

Sensitive Element as the Conversion Element (without a separate conversion element): Some semiconductor sensors directly convert the measured quantity into an electrical signal without the need for an intermediate conversion step. For example, in a semiconductor gas sensor, the “semiconductor material” (sensitive element) directly detects gas concentration changes, causing a change in its resistance, which is then converted into an electrical signal.

Conclusion

The sensor’s composition is not a “fixed template” but a flexible architecture designed to efficiently complete the conversion from “measured quantity to usable signal.” The core principle is “sensing → conversion → processing,” and the components are theoretically divided based on function. In practice, the structure can be simplified or integrated depending on the principle, precision requirements, and application scenarios.

The key principle is that, regardless of the structure’s complexity, the sensor must meet the “input (measured quantity) → output (usable signal)” correspondence and achieve the specified precision. This is the core criterion for evaluating sensor performance.

Understanding the sensor’s composition is essentially understanding the complete chain from “sensing physical changes” to “outputting standard signals,” which is the foundation for learning about sensor classification, selection, and application.