Bimetal thermometers are widely used mechanical temperature measurement devices known for their robust design, wide temperature range, and ability to function without external power supply. Based on the principle of thermal expansion, they convert temperature changes into mechanical displacement via bimetallic strips, which drive a pointer on a dial for direct reading. Due to their simplicity, durability, and cost-effectiveness, they are extensively applied across industrial, civil, and special-purpose scenarios.

1. Industrial Applications

● Petrochemical Industry

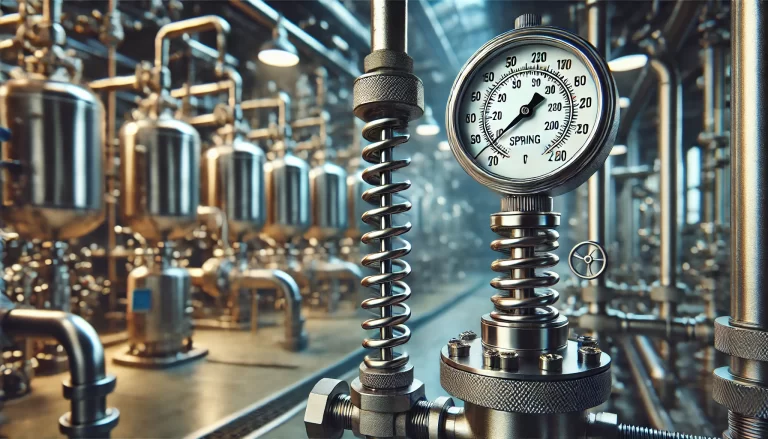

Bimetal thermometers are essential for temperature monitoring of reaction vessels, storage tanks, and pipelines, especially in high-temperature and high-pressure environments. In refineries, for instance, they are used to monitor the temperature of fluid catalytic cracking (FCC) units to ensure process stability and safety.

● Steel and Metallurgy

They are used to measure and control the temperature in blast furnaces, continuous casting machines, and rolling mills. Real-time temperature monitoring ensures optimal metalworking conditions and prevents process deviations that could affect product quality.

● Power and Energy Sector

Bimetal thermometers are used for temperature control in generators, transformers, and other high-power equipment. Monitoring ensures preventive maintenance and helps avoid overheating-related failures.

2. Civil and Infrastructure Applications

● Food Processing

Precise temperature control is crucial in processes such as baking, sterilization, fermentation, and pasteurization. Bimetal thermometers are widely used in production lines for dairy products, baked goods, and canned foods.

● Household Appliances

These thermometers are often integrated into appliances such as air conditioners, water heaters, ovens, and refrigerators, enabling automatic thermal regulation and safety cutoffs.

● District Heating Systems

In urban heating networks and residential hot water systems, bimetal thermometers are used to monitor circulating water temperature, ensuring energy efficiency and comfortable indoor environments.

3. Special Application Scenarios

● Hazardous or Explosion-Prone Environments

Explosion-proof (Ex) models are designed for use in chemical plants, refineries, gas pipelines, and underground mining, where flammable gases or vapors may be present. These instruments comply with IECEx, ATEX, or national Ex standards.

● Automation and Data Acquisition

Bimetal thermometers can be integrated with temperature transmitters or signal converters, enabling real-time data acquisition, feedback, and integration with DCS/PLC systems in automated production lines.

4. Technical Advantages

Wide Operating Temperature Range

Standard models can operate reliably from -40°C to +550°C, making them suitable for both cryogenic and high-temperature conditions.Power-Free Operation

Mechanical design eliminates the need for external power, enhancing reliability and reducing maintenance costs.High Mechanical Strength & Vibration Resistance

The rugged construction and sealed casing allow stable operation under vibrating, humid, or dusty conditions.Accuracy

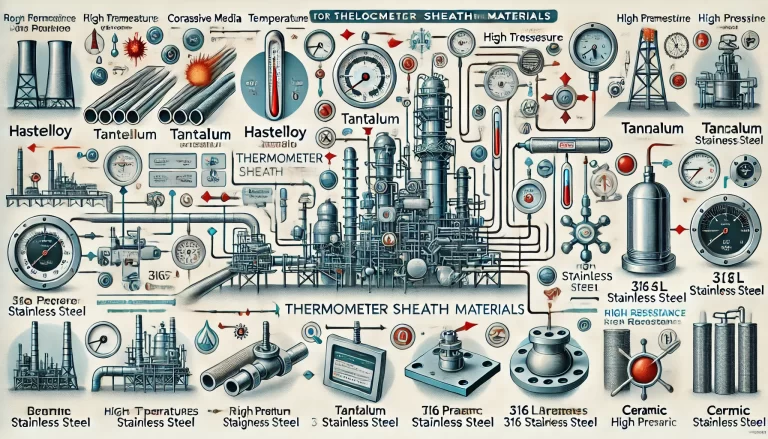

Typical accuracy classes are ±1.0% or ±1.5% of full scale, complying with national or international standards such as EN 13190 or GB/T 12149.Corrosion-Resistant Materials

Available in 304/316 stainless steel, PTFE-coated stems, or special alloys for corrosive environments, ensuring compatibility with a wide range of industrial media.Customization Options

Dial size, stem length, mounting thread, protective sheath, and pointer design can be tailored to suit specific site conditions or user requirements.

Conclusion

Bimetal thermometers remain a cost-effective and practical solution for temperature measurement in numerous fields. Their durability, ease of use, and maintenance-free operation make them a preferred choice for both traditional and modern industries. When integrated with automation systems or designed for explosion-proof environments, their applicability becomes even broader.