Overview

Control system inspections are essential for preventing failures and ensuring system reliability. A standardized process should be established across three main aspects: hardware, software, and functionality.

1. Preparation for Inspection

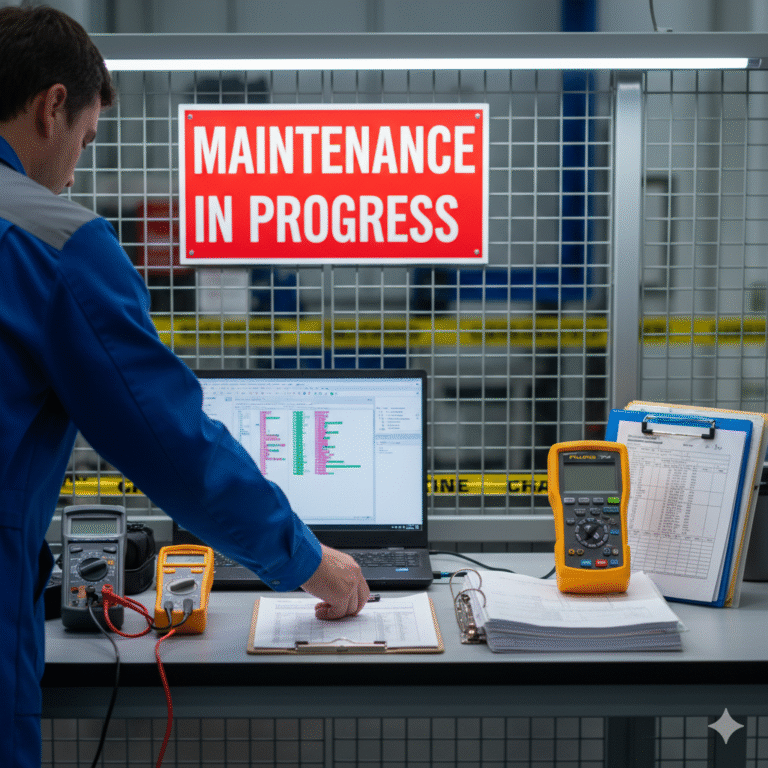

Tools and Instruments:

Multimeter

Signal generator

Programming software (e.g., PLC programming software)

Calibration instruments (e.g., Fluke 754)

Documents:

Control system schematics

I/O list

Inspection checklist

Historical fault records

Safety Measures:

Ensure the system is in a non-operational state or isolated before inspection.

Hang a “Maintenance in Progress” sign.

If dealing with high-risk processes, obtain a work permit as required.

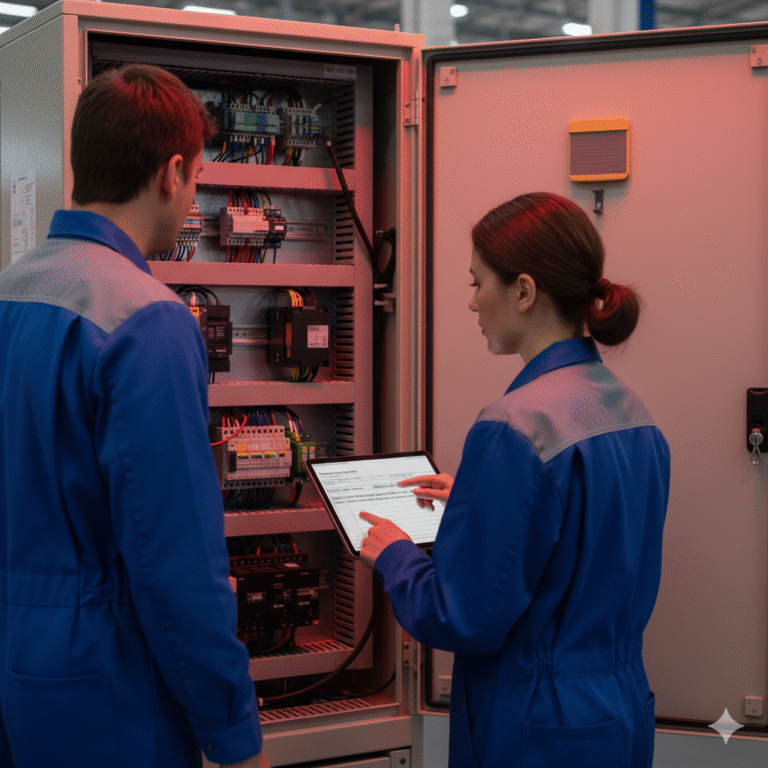

2. Inspection Items and Frequency

Inspection items should cover all critical components of the control system. The frequency of inspections should be defined based on the manufacturer’s recommendations, system complexity, and past fault history.

Regular checks on the following should be included:

Power supply

CPU status

Signal integrity

Control module health

Communication interfaces

3. Abnormal Handling and Records

Problem Classification:

Urgent Issues (e.g., power failure, CPU crash): Immediately shut down and repair the system.

General Issues (e.g., signal deviation): Record the issue and address it within a specified period (e.g., 24 hours).

Inspection Record:

Fill in the Control System Inspection Form, which includes:

Inspection items

Results

Descriptions of abnormalities

Responsible personnel

Resolution times

This form serves as a maintenance record for the equipment.

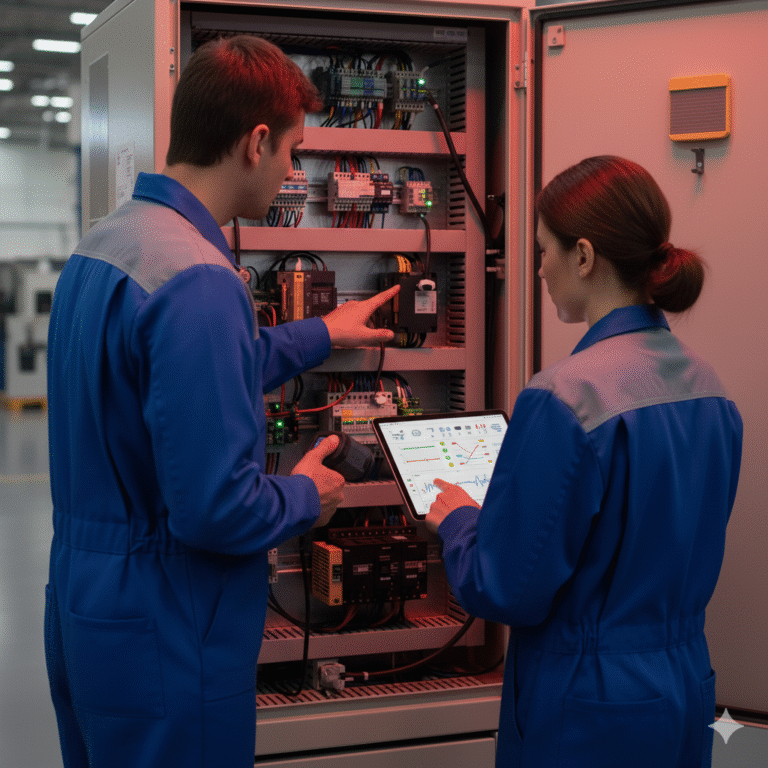

4. Advanced Inspection Strategies

Predictive Maintenance:

Use vibration sensors and temperature sensors to monitor critical components within the control cabinet (e.g., power modules). This approach helps to detect potential failures before they occur.Personnel Training:

Regularly conduct training for inspection personnel, focusing on the use of tools like oscilloscopes and logic analyzers. Emphasize troubleshooting processes for common failures such as communication disruptions and module damage.

Conclusion

A well-executed control system inspection process enhances system reliability, reduces downtime, and extends the service life of the equipment. By incorporating predictive maintenance and continuous training, organizations can minimize the risk of unexpected failures and optimize operational efficiency.