1. Introduction

In modern industrial automation and precision manufacturing, instruments play a crucial role in measuring, monitoring, and controlling various physical parameters such as temperature, pressure, and level.

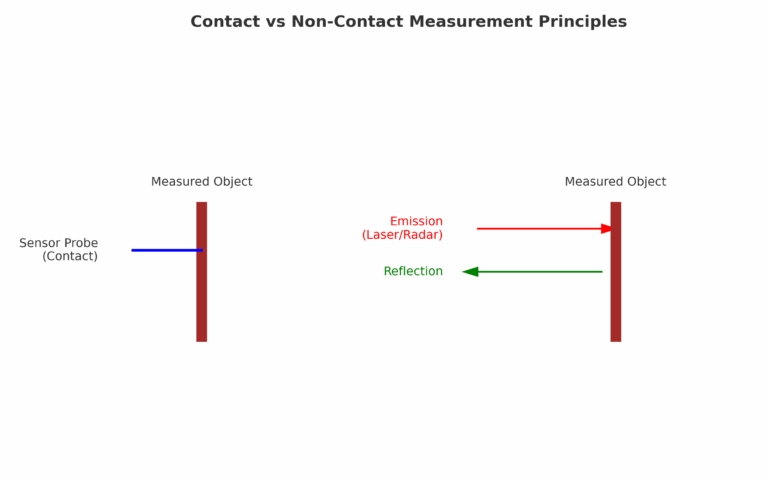

Based on the measurement method, industrial instruments can be classified into contact-type and non-contact types. Contact-type instruments acquire data by physically touching the target, whereas non-contact instruments measure remotely using electromagnetic, optical, or acoustic technologies.

This article explains the working principles, advantages and disadvantages, and typical applications of both types, followed by a direct comparison.

2. Contact-Type Industrial Instruments

Definition: Instruments that obtain measurement data through direct contact with the measured medium or object.

Typical Examples:

Temperature sensors: Thermocouples, RTDs (Resistance Temperature Detectors), thermistors.

Pressure sensors: Diaphragm-based pressure transmitters, bourdon tubes.

Level instruments: Tuning fork level switches, magnetic float level gauges, capacitive level sensors.

Dimension and material testers: Calipers, micrometers, hardness testers, tensile testers.

2.1 Working Principle

Contact-type instruments detect physical changes (voltage, resistance, displacement, etc.) caused by direct interaction with the target medium.

Temperature Measurement: Contact thermocouples and RTDs detect temperature-dependent changes in voltage or resistance.

Pressure Measurement: Diaphragms deform under fluid pressure, with the displacement converted into an electrical signal.

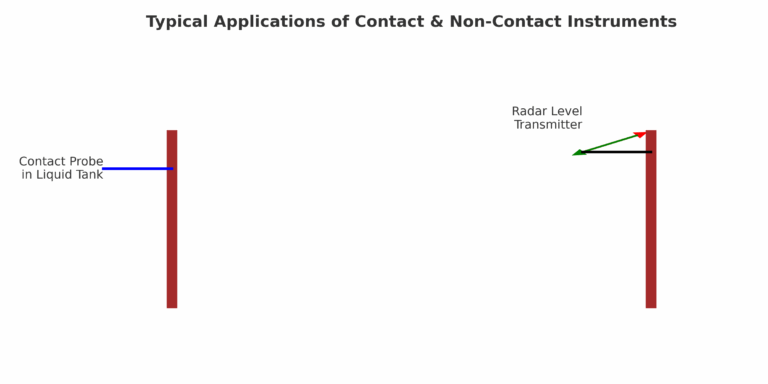

Level Measurement: Probes directly interact with liquids or solids; changes in vibration, capacitance, or buoyancy indicate level variation.

2.2 Advantages

High accuracy in stable conditions.

Mature technology with relatively low manufacturing cost.

Good stability due to simple working principles.

2.3 Disadvantages

Surface influence: Contact may damage delicate surfaces or cause contamination.

Limited environmental tolerance: Susceptible to damage under extreme temperature, pressure, or corrosive conditions.

Maintenance requirement: Probes can wear or foul, requiring regular calibration and cleaning.

2.4 Typical Applications

Quality control in machining (e.g., dimensional checks with calipers).

Material hardness and tensile strength testing.

Liquid and bulk solid level monitoring in chemical, petrochemical, and food industries.

3. Non-Contact Industrial Instruments

Definition: Instruments that measure physical quantities without physically touching the medium, typically using electromagnetic waves, lasers, or ultrasonic waves.

Typical Examples:

Laser rangefinders

Infrared thermometers

Radar level transmitters

Ultrasonic level meters

Laser displacement sensors

3.1 Working Principle

Laser Rangefinding: Measures the time of flight of a laser beam reflected from the target.

Infrared Temperature Measurement: Detects infrared radiation emitted by the object.

Radar Level Measurement: Uses microwave radar signals to detect level based on echo time.

Ultrasonic Measurement: Measures time delay of ultrasonic echoes reflected from a surface.

3.2 Advantages

No contact damage: Suitable for fragile, hot, or moving objects.

Extreme environment adaptability: Performs well under high temperature, high pressure, or corrosive conditions.

Remote measurement capability: Allows safe monitoring of hazardous or inaccessible areas.

3.3 Disadvantages

Environmental influence on accuracy: Dust, steam, and turbulence may affect readings.

Higher cost: More complex technology with higher initial investment.

Requires precise alignment and configuration.

3.4 Typical Applications

High-temperature measurement in steelmaking using infrared thermometers.

Remote monitoring in hazardous areas (petrochemical plants).

Level measurement in high-pressure or corrosive tanks.

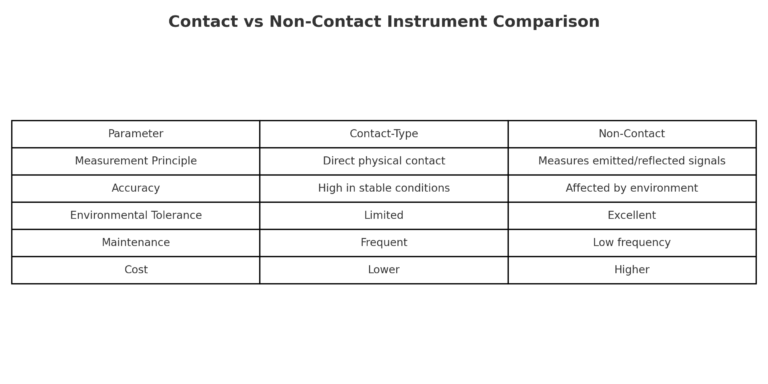

4. Contact vs. Non-Contact Instruments — Comparison Table

| Parameter | Contact-Type Instruments | Non-Contact Instruments |

|---|---|---|

| Measurement Principle | Direct physical contact with target | Measures emitted/reflected energy (laser, radar, ultrasound) |

| Accuracy | High under stable conditions | May be affected by environmental factors |

| Environmental Tolerance | Limited (can be damaged by high temp/pressure/corrosion) | Excellent — suitable for extreme environments |

| Maintenance | Requires regular calibration and cleaning | Lower maintenance frequency |

| Cost | Generally lower | Higher initial cost |

| Typical Applications | Dimensional checks, hardness testing, direct immersion level measurement | Remote level measurement, high-temperature monitoring, hazardous area monitoring |

5. Conclusion

Both contact-type and non-contact industrial instruments are indispensable in modern industry.

Contact-type devices are ideal for high-accuracy measurements where direct interaction is feasible.

Non-contact devices excel in hostile environments and remote measurement scenarios.

Choosing the right instrument depends on application environment, accuracy requirements, and budget considerations.