In the industrial field, radar level meter process connection gasket is a very important accessory, which is mainly used for sealing and isolating the connection between pipelines, valves, pumps and other equipment, in order to prevent media leakage and external impurities from entering the system.

In this article, we will introduce in detail the use, classification and importance of process connection gasket in the industrial field.

Process connection gaskets are mainly used in the connections between various pipelines, valves, pumps and other equipment, and their role is to provide reliable sealing performance to prevent media leakage and external impurities from entering the system. The use of gaskets can greatly improve the reliability and safety of the equipment, reduce the frequency of maintenance and replacement, reduce the production costs of enterprises.

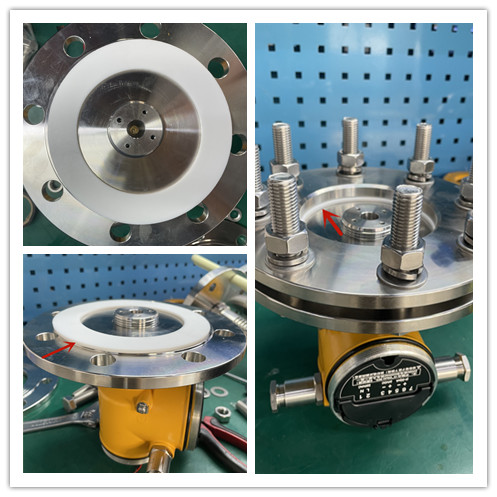

Process connection gasket has a variety of different types, the following is one of several common classification: process connection gasket according to material can be divided into metal gasket, non-metallic gasket and semi-metallic gasket.

Metal gaskets including stainless steel, copper, aluminum and other metal materials made of gaskets; non-metallic gaskets including rubber, polytetrafluoroethylene (PTFE), asbestos and other materials made of gaskets; semi-metallic gaskets refers to a combination of metal and non-metallic materials gaskets. Process connection gaskets can be divided into flat gaskets, O-shaped gaskets, winding gaskets and so on according to the shape.

Flat gasket is the most common type of gasket, mainly used for flange connection; O-shaped gasket is mainly used for round pipe connection; winding gasket is made of metal and non-metallic tape spiral winding, has good compression and resilience. Process connection gasket according to the use of temperature can be divided into low-temperature gaskets, room temperature gaskets and high-temperature gaskets.

Low-temperature gaskets are suitable for low-temperature environments, such as gaskets made of polytetrafluoroethylene; room-temperature gaskets are suitable for room-temperature environments, such as rubber gaskets; high-temperature gaskets are suitable for high-temperature environments, such as high-temperature-resistant asbestos gaskets.

Process connection gasket according to the use of pressure can be divided into low-pressure gaskets, medium pressure gaskets and high-pressure gaskets. Low-pressure gaskets are suitable for low-pressure pipeline connections; medium-pressure gaskets are suitable for medium-pressure pipeline connections; high-pressure gaskets are suitable for high-pressure pipeline connections, such as petrochemical pipelines.

The role of process connection gaskets is very important in industry. First of all, it can ensure the normal operation of the equipment, and prevent media leakage and external impurities into the system, thus ensuring the stability and safety of production.

Secondly, the use of a process connection gasket can extend the service life of the equipment, reduce the frequency of maintenance and replacement, and reduce the production cost of enterprises.

In addition, high-quality gaskets can also improve the sealing performance of the equipment, reduce the waste of energy, and create more economic benefits for the enterprise.