Introduction

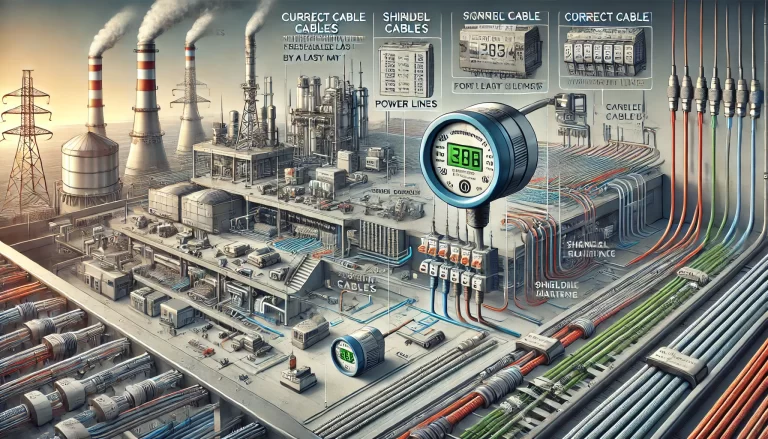

In petrochemical production, automation instruments are the nervous system of the process. They play a critical role in ensuring operational stability, safety, and efficiency. Failures or inaccuracies in these instruments can lead to production losses or even severe safety hazards. This article presents a comprehensive methodology for troubleshooting typical issues in temperature, flow, pressure, and level measurement systems, emphasizing practical field diagnosis.

1. General Troubleshooting Philosophy

Instrumentation issues can generally be divided into two categories:

Process-related issues: Instruments correctly reflect actual abnormal process conditions.

Instrument-related issues: Faults or malfunctions in the instrument or measurement circuit cause incorrect readings.

Since both scenarios often present similar symptoms, technicians must combine their understanding of the measurement system with knowledge of the process conditions to make accurate judgments. A successful diagnosis relies on proficiency in instrument principles and structures, familiarity with the process medium, and collaboration with operations personnel.

2. Temperature Instrument Troubleshooting

2.1 Common Symptoms

Indications too high or too low

Readings are static or change very slowly

Sudden jumps or oscillations

2.2 Typical Causes and Analysis

Sudden temperature increase: May be due to broken thermocouple wires, terminal loosening, or open circuits. Use a multimeter to measure resistance or millivolts at multiple points.

Sudden temperature drop: Often caused by short circuits or sensor element failure. Focus on cable joints and bends.

Unstable temperature readings: Might be linked to process fluctuations or control loop issues.

2.3 Field Diagnosis Checklist

Confirm correct sensor installation (liquid/gas phase)

Inspect wiring for damage or incorrect polarity

Compare local measurements with control room display

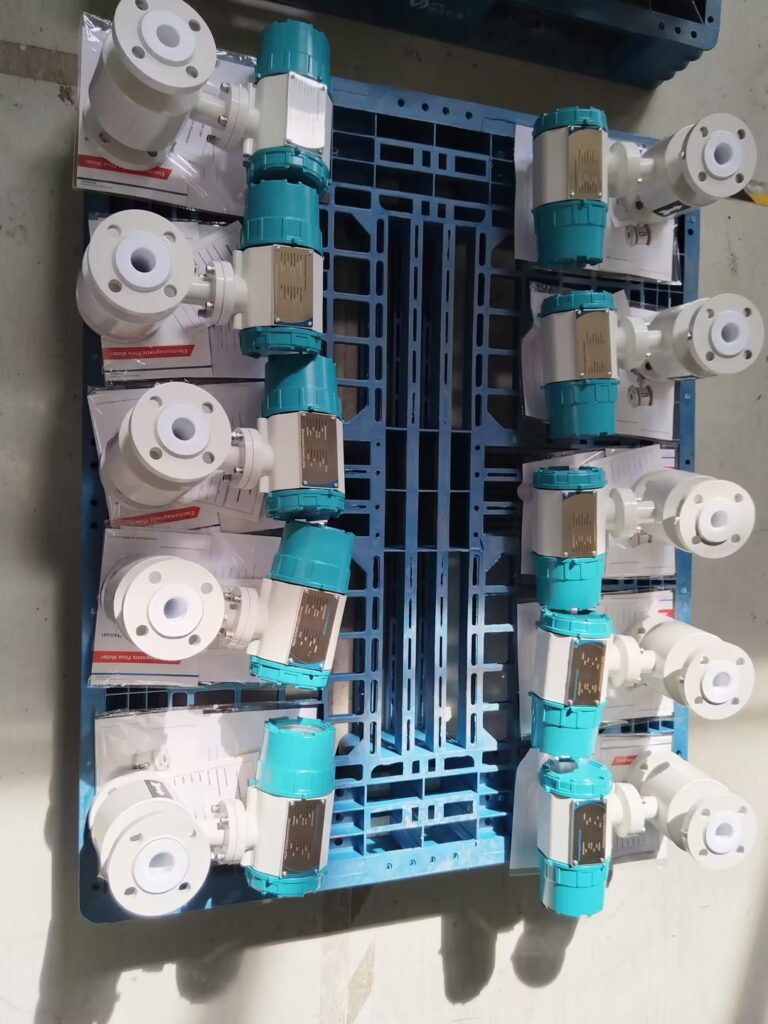

3. Flow Instrument Troubleshooting

3.1 Common Symptoms

Indications zero, unusually high or low

Signal fluctuates or is unstable

3.2 Typical Causes and Analysis

Zero flow indication: May result from blocked impulse lines, faulty primary element (e.g., orifice plate), or transmitter power failure

Full-scale reading: Often due to vacuum side blockage or leakage

Fluctuating flow readings: Could be due to trapped air, cavitation, improper tuning of PID loop, or pump instability

3.3 Diagnostic Tips

Cross-check with pump operation and valve positions

Inspect both positive and negative impulse lines for blockages

Look for pressure imbalances or trapped bubbles in differential pressure systems

4. Pressure Instrument Troubleshooting

4.1 Common Symptoms

No response, flat line, or irregular jumps

Output drifts suddenly

4.2 Typical Causes and Analysis

Sudden changes or no indication: Likely blockage in impulse lines or isolation valves. Seasonal freezing or clogging due to process medium is also common.

Large pressure swings: Often a process-induced issue, but may also involve control loop oscillations

4.3 Inspection Points

Check root valves and vent lines

Inspect for leaks or corrosion in tubing

Verify transmitter zero-point and range

5. Level Instrument Troubleshooting

5.1 Common Symptoms

Static or frozen reading

Indication mismatch with local sight glass

Large variations in reading

5.2 Typical Causes and Handling

Indication too high: Air pockets or liquid shortages in negative impulse line

Indication too low: Positive line blockage or balance valve fully closed

Mismatch between DCS and field indicator: Could be due to calibration drift or installation issues

5.3 Corrective Measures

Drain and refill impulse lines using consistent procedures

Manually simulate level changes and observe sensor response

Adjust or recalibrate transmitters if necessary

6. Simple Control Loop Faults

6.1 Common Issues

Erratic loop behavior

Overshoot or slow response

6.2 Causes and Troubleshooting Steps

Confirm loop architecture (sensor – controller – valve)

Evaluate PID parameters and retune if necessary

Inspect air supply, signal wiring, and valve positioner

7. Common Control Valve Faults

7.1 Typical Faults and Causes

Valve not moving: No signal pressure, actuator failure, stem jamming

Valve moves but no control effect: Detached plug, blocked flow path

Valve unstable or oscillates: Oversized valve, improper flow direction, or mechanical wear

Valve sticks or lags: Packing friction, actuator leaks, or internal fouling

Excessive leakage: Damaged seats or foreign particles lodged in sealing surfaces

Conclusion

Effective troubleshooting requires a holistic view of the process and instrument systems. Collaboration with operations personnel and a structured diagnostic approach helps narrow down issues quickly. By integrating field experience with technical knowledge, instrumentation teams can minimize downtime, improve accuracy, and ensure safe, continuous operations.