Introduction and Objectives

Background:

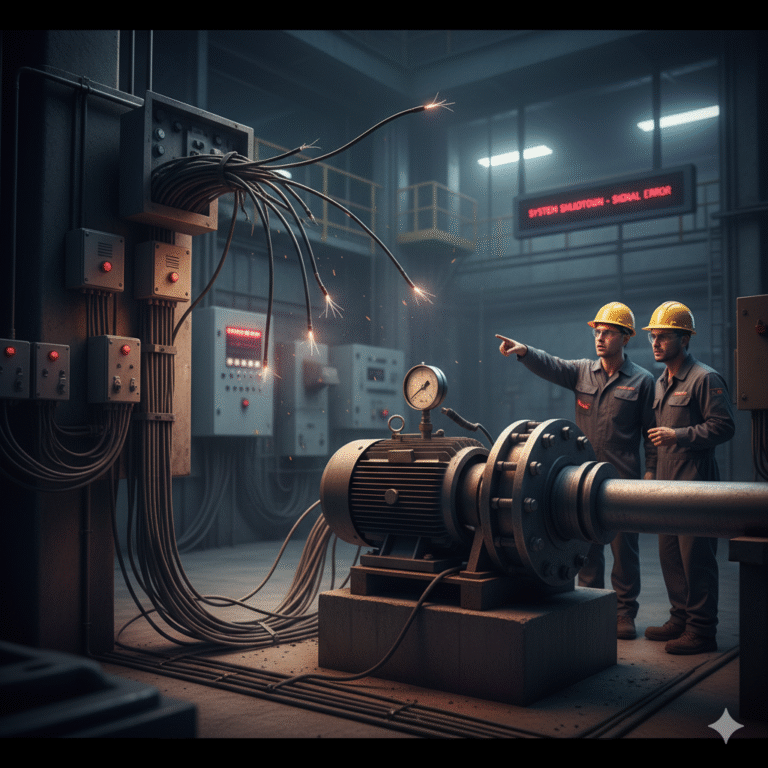

In industries such as chemical production, thermal power generation, metallurgy, and mining, equipment like pumps, coal mills, and turbines often generate high-frequency vibrations. These vibrations pose significant risks to the reliability of instrument wiring. Loose, improperly connected, or broken wires can cause measurement signal fluctuations and distortions, leading to false alarms, system shutdowns, and severe safety and production issues.

Objective:

This solution aims to address wiring issues caused by high-frequency vibrations by implementing a set of advanced connection technologies, special materials, system architecture optimization, and program redundancy. The primary goals are to:

Prevent unplanned shutdowns caused by vibrations.

Reduce the failure rate of instrument wiring.

Improve signal measurement quality and system reliability.

Ensure ease of equipment maintenance and cost-effectiveness.

Measures and Benefits Analysis

The corrective measures follow a “layered defense” strategy, combining both hardware and software solutions to create reliable protection.

Layer 1: Mechanical Reinforcement (Eliminating Physical Loosening)

This layer focuses on the physical properties of the connection points, serving as the foundation and key defense line.

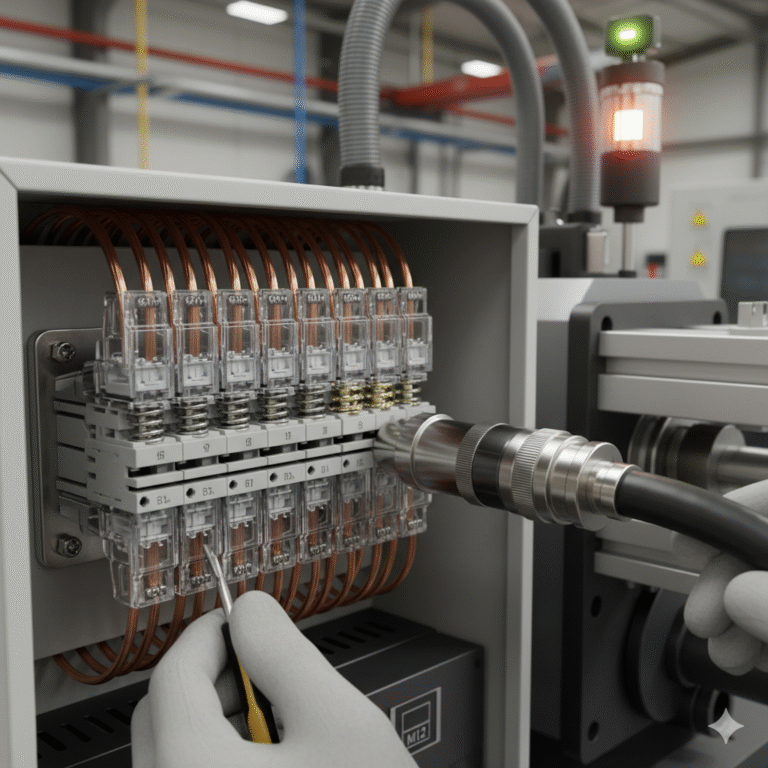

Spring-loaded Terminal Blocks:

Solution: Replace traditional screw-type terminal blocks with vibration-resistant spring-loaded terminals in all vibration-prone areas such as instrument junction boxes, intermediate wiring boxes, and system cabinets.

Advantages: The spring continuously tightens the connection as vibration occurs, ensuring a secure connection that resists loosening.

Challenges: Higher initial investment costs than traditional terminals and requires special tools for installation and removal.

Spring Washers:

Solution: Install spring washers or combination washers at all screw connections between terminal lugs and terminal blocks.

Advantages: Simple implementation, low cost, and effective in preventing loosening from vibration.

Challenges: May fail under continuous heavy vibration, requiring regular inspection and replacement.

Industrial-grade Connectors:

Solution: For highly vibrating or frequently serviced equipment, prioritize using standard M12/M8 industrial connectors with aerospace-grade contacts.

Advantages: Excellent vibration resistance, quick connect/disconnect for easy maintenance, and sealed for waterproof and dustproof performance.

Challenges: Higher cost and need for compatible sockets and cables.

Layer 2: Material Solidification (Eliminating Relative Motion)

This layer uses materials to bond multiple components into a single unit, preventing relative movement.

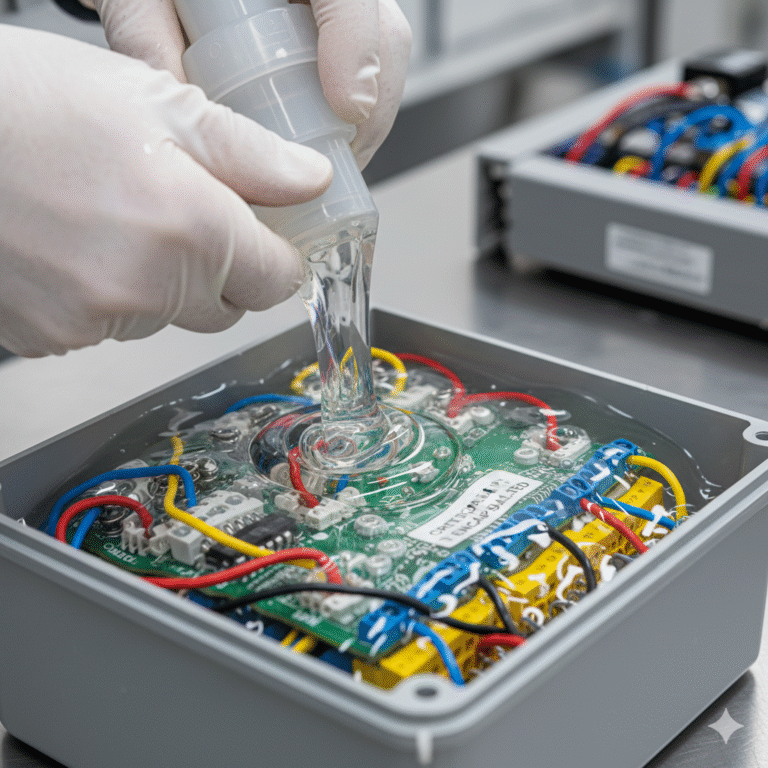

Silicone Gel Encapsulation:

Solution: For critical measurement point junction boxes with high failure rates, use flexible silicone gel for encapsulation.

Advantages: Eliminates relative motion between components, excellent waterproof and corrosion-resistant properties, and effectively addresses stubborn vibration issues.

Challenges: Difficult to maintain, as it requires destructive removal for repairs. Not suitable for high-temperature environments, and modifications are nearly irreversible.

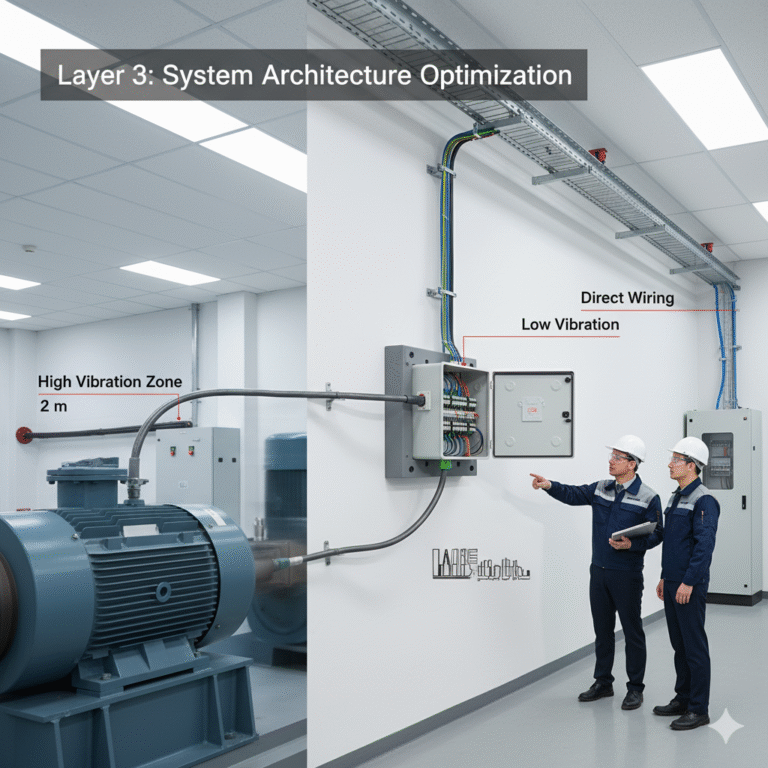

Layer 3: System Architecture Optimization (Isolating Risks)

This layer aims to limit vibration impact within specific areas by optimizing the system layout.

Vibration Isolation Junction Boxes:

Solution: Place intermediate junction boxes in areas with low vibration, but close to vibration sources, to separate permanent connections in high-vibration areas from maintainable connections in low-vibration zones.

Advantages: Enhances system reliability and ease of maintenance, simplifying troubleshooting.

Challenges: Requires additional space, investment, and introduces more complexity to the system.

Direct Wiring Connections:

Solution: Directly connect sensor wires from the equipment to the junction box, bypassing intermediate terminals, for reliable and low-resistance connections.

Advantages: Simple implementation, low cost, and eliminates terminal loosening failures.

Challenges: Requires cutting wires for maintenance, making them shorter over time. Doesn’t comply with certain standards requiring disconnectable test points.

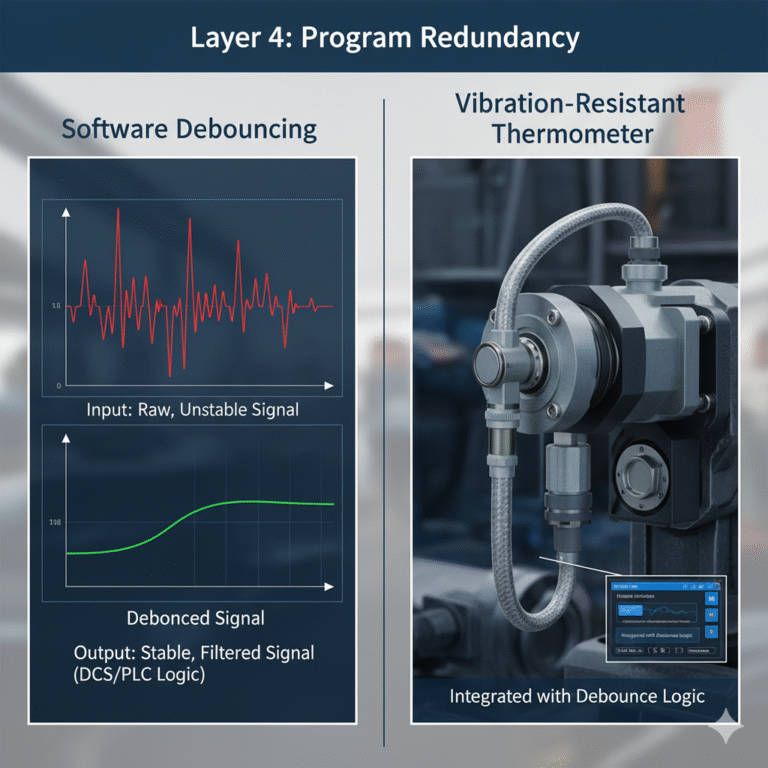

Layer 4: Program Redundancy (Enhancing System Fault Tolerance)

This layer addresses the inherent limitations of hardware by tolerating temporary faults through control logic.

Signal Debouncing Software:

Solution: Implement software filters (e.g., delay, rate limiting, moving averages) in DCS/PLC systems for all critical analog signals to reduce spurious readings.

Advantages: Cost-effective, simple, and highly effective in distinguishing between real faults and connection issues.

Challenges: Potential to mask actual process anomalies, requiring careful parameter tuning to avoid over-filtering.

Vibration-Resistant Thermometers:

Solution: Use specially designed vibration-resistant thermometers for temperature measurements, in combination with signal debouncing software.

Advantages: Improved mechanical durability and protection against vibration.

Challenges: Higher cost and requires program integration for maximum effectiveness.

Key Considerations

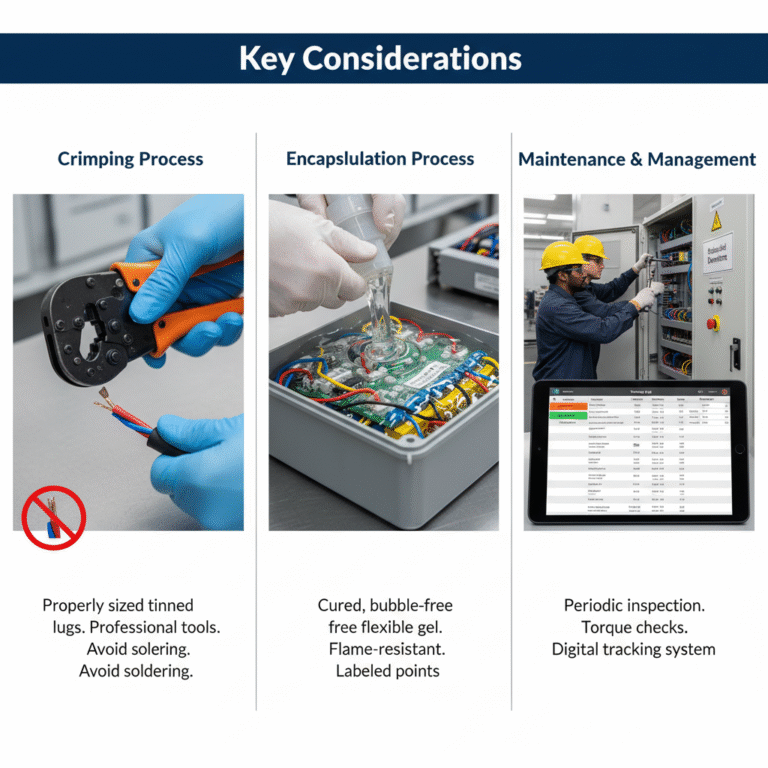

Crimping Process:

Requirements: Never use tin-plating on multi-strand copper wires, as soldered joints lack elasticity and are prone to fatigue and breakage under vibration. Use appropriately sized tinned copper lugs and professional crimping tools to ensure secure connections with low contact resistance.

Encapsulation Process:

Requirements: Ensure correct wiring before encapsulation and label each point for identification. Use flexible, flame-resistant, low-stress silicone gel to guarantee long-term vibration resistance without cracking. Ensure the encapsulation is filled properly, with no air bubbles.

Maintenance and Management:

Preventive Maintenance: Even with the measures above, periodic inspections and tightening of connections in vibration-prone areas are still necessary during scheduled downtime.

Tracking System: Create a log for modified measurement points, especially those with gel encapsulation or aerospace connectors, including the date and method of correction for future reference.

Conclusion

Addressing wiring issues in high-frequency vibration environments requires a comprehensive, multi-layered approach. This strategy integrates mechanical reinforcement, system isolation, material solidification, and program redundancy. Through these combined measures, we can build a highly reliable and maintainable wiring system, ensuring long-term operational stability and safety.