In industrial automation, the accuracy and stability of instrumentation and control systems are paramount to ensuring efficient and safe operations. A thorough examination of these systems is essential to prevent costly errors and potential safety risks. This article outlines the key areas for review, including control system hardware and software, instrumentation accuracy and installation, and the safety interlock system. Each component requires careful inspection to ensure optimal performance and reliability.

1. Control System: Hardware Configuration and Software Functionality

Hardware Configuration Verification

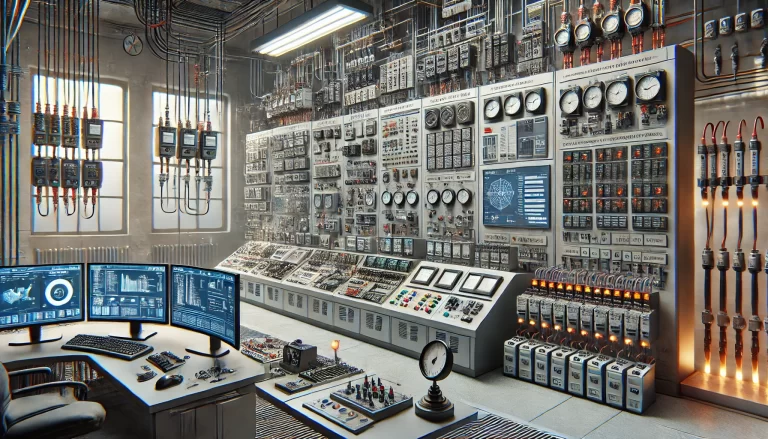

The control system’s hardware configuration forms the backbone of the entire system, including critical components such as controllers, Input/Output (I/O) modules, and other connected devices. Verifying that these components match the design specifications is crucial. This involves checking whether the correct number and type of controllers and I/O modules have been installed and confirming that they are compatible with the system architecture.

For example, a mismatch between I/O module types and the actual requirements could result in data processing errors or delayed control responses. It is essential to ensure that all hardware is not only correctly specified but also installed in compliance with industry standards, including proper wiring and grounding. The physical integrity and durability of the hardware are important to prevent malfunctions due to environmental conditions like vibration or temperature changes.

Software Functionality Review

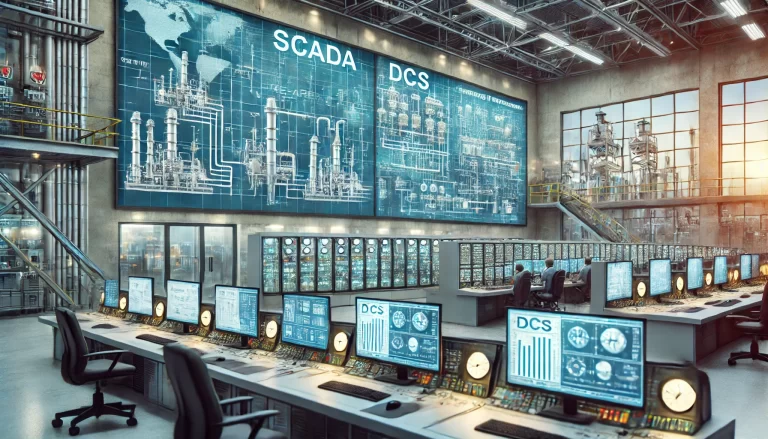

Control system software handles all automation tasks, including executing control logic, managing alarms, and integrating with external systems. The logic implemented within the software must be reviewed to ensure that it performs as expected in all operational conditions.

Alarm management is another critical aspect of the software. Properly configured alarms help operators respond quickly to abnormal conditions, reducing downtime and preventing accidents. However, poorly set alarms (either too many or too few) can lead to alarm fatigue or missed signals. A graded alarm system—where alarms are prioritized by severity—can greatly enhance system usability and safety.

Communication Network Stability

The communication network is the nerve center of modern control systems, facilitating the exchange of data between various components. Any disruption in this communication could lead to serious control failures. It is essential to verify that the communication protocols used (such as Modbus, PROFIBUS, or Ethernet/IP) are correctly implemented and that network traffic is stable and free of bottlenecks.

High-availability communication networks, especially in systems that rely on real-time data (such as continuous process control), should be rigorously tested. Network redundancy measures—such as using dual-ring networks or backup communication links—can help ensure that even in the case of hardware failures, data flow remains uninterrupted. Checking for data packet loss, latency, and jitter during routine network operation helps confirm that the system is performing as expected.

2. Instrumentation: Accuracy, Installation, and Signal Integrity

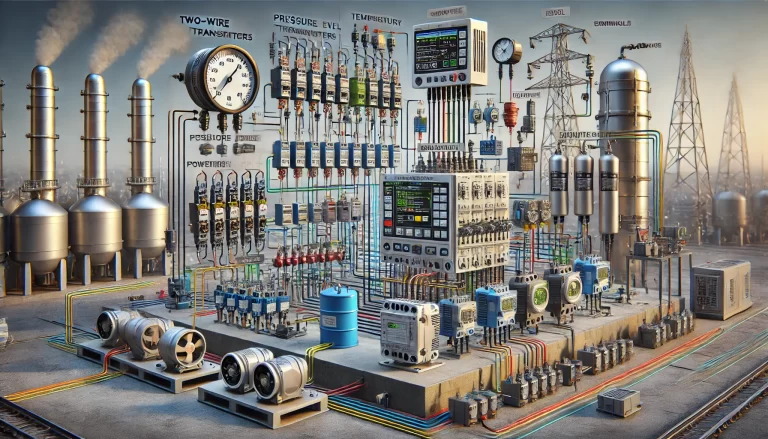

Instrument Accuracy and Range

Instrumentation is used to measure vital parameters such as pressure, temperature, flow, and level within a process. The accuracy and range of these instruments must match the process requirements. If the chosen instruments are not sensitive enough or are incorrectly calibrated, they could provide erroneous data, leading to inefficient operation or, worse, safety hazards.

For example, a pressure sensor used in a high-pressure system must have a sufficient range to handle potential pressure spikes. Instruments should also be checked regularly for calibration accuracy, ensuring that they deliver precise measurements over time. Regular calibration against a known standard will help maintain instrument reliability.

Installation and Signal Types

Instrumentation should be installed in locations that allow for easy access during maintenance while ensuring the instruments are not exposed to excessive heat, dust, or other damaging environmental factors. Poor installation practices can reduce the lifespan of instruments and make routine checks more difficult.

Signal types used by instruments—whether analog (e.g., 4-20 mA current loops) or digital—must also be correct for the intended control system. The wiring configuration must be checked to avoid noise interference, which can distort readings. In noisy environments, using shielded cables or separating power and signal lines can reduce interference. Moreover, grounding techniques should be implemented correctly to avoid ground loops that may introduce errors into sensitive measurements.

Environmental Protection and Hazardous Areas

Instruments are often installed in harsh environments where they are exposed to moisture, dust, extreme temperatures, or corrosive substances. In such cases, instruments must meet specific protection ratings, such as IP (Ingress Protection) ratings for water and dust protection or NEMA ratings for industrial environments. Ensuring that the selected instruments meet these protection standards helps prolong their life and reliability.

In hazardous locations (such as areas with flammable gases or dust), instruments must also comply with safety certifications such as ATEX or IECEx. These certifications ensure that the instruments can operate safely without igniting surrounding materials.

3. Safety Interlock System: Logic, Devices, and Testing

Safety Interlock Logic Verification

A safety interlock system is designed to prevent unsafe conditions by shutting down equipment or processes when predefined conditions are breached. The logic governing these interlocks should be thoroughly reviewed to ensure it responds appropriately to unsafe situations. This includes simulating emergency scenarios to ensure that the interlocks engage as expected.

For instance, a chemical reactor may have temperature interlocks that prevent overheating. If the logic governing these interlocks is not correctly implemented, the system may fail to stop the reactor, leading to catastrophic failure. Therefore, regular simulations and tests of the interlock logic are essential for verifying its robustness.

Interlock Device Responsiveness and Reliability

In addition to software-based logic, physical devices such as emergency stop buttons, limit switches, and pressure relief valves form a critical part of the safety interlock system. These devices must be tested to ensure that they trigger immediately when activated. A non-responsive or delayed action in these devices could render the safety system ineffective.

Physical wear and tear can reduce the reliability of these devices, so periodic inspections and maintenance are necessary. Tests should include not only routine functionality checks but also stress tests under real or simulated fault conditions.

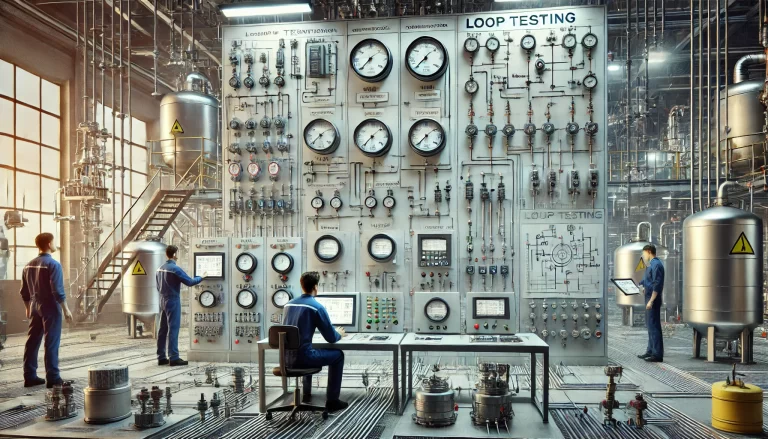

Testing and Validation Documentation

A properly functioning safety interlock system requires thorough testing and validation before being deployed in the field. All test procedures should be documented, detailing the conditions under which the tests were conducted, the results, and any corrective actions taken. The system’s logic and hardware should be validated against safety standards such as ISO 13849 or IEC 61508, which govern the safety integrity levels (SIL) for industrial systems.

Maintaining detailed test records ensures that the system’s safety performance can be audited, providing a paper trail for regulatory compliance. These records should also be reviewed regularly to identify patterns in test failures that may indicate underlying issues with system design or maintenance.

Conclusion

The reliable and safe operation of instrumentation and control systems is critical in industrial processes, where any failure can lead to production losses or severe safety incidents. By rigorously checking hardware configurations, verifying software functionality, ensuring instrumentation accuracy, and thoroughly testing safety interlocks, operators can mitigate risks and enhance system performance. Routine maintenance and testing, combined with thorough documentation, provide the necessary framework for long-term system reliability and regulatory compliance.