1. Fundamental Principle

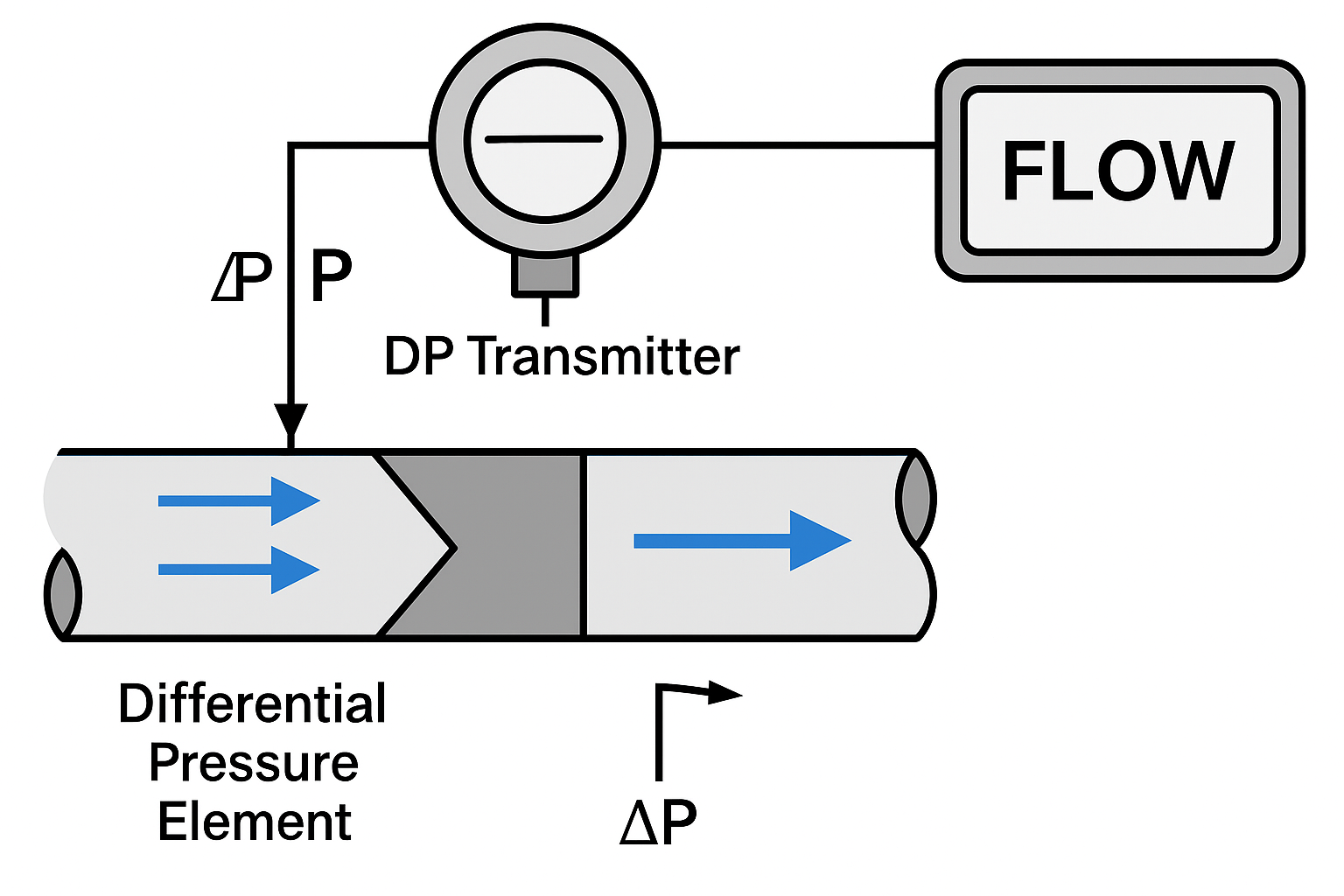

Differential pressure (DP) flow meters operate on the throttling principle, derived from the Bernoulli equation. They calculate flow rate by measuring the static pressure difference generated as the fluid passes through a restriction (such as an orifice plate or venturi tube), and combining it with known physical parameters.

1.1 Working Principle

When a fluid flows through a throttling device (e.g., orifice plate, nozzle, venturi tube), the flow accelerates and pressure drops at the constriction, generating a pressure difference (ΔP) proportional to the square of the flow rate.

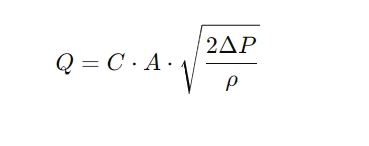

1.2 Core Equation

Where:

Q: Volumetric flow rate

C: Flow coefficient (dependent on the device geometry and Reynolds number)

A: Throat cross-sectional area

ρ: Fluid density

ΔP: Differential pressure

2. Types of DP Flow Meters and Throttling Devices

| Type | Structure & Characteristics | Advantages | Limitations | Applications |

|---|---|---|---|---|

| Orifice Plate | Simple concentric bore | Standardized, low cost, wide usage | High pressure loss, lower accuracy | Clean gases/liquids |

| Flow Nozzle | Curved inlet, cylindrical outlet | Higher accuracy, wear-resistant | Costlier, more complex | High-speed/high Re number fluids |

| Venturi Tube | Converging-throat-diverging profile | Minimal pressure loss, high accuracy | Bulky, expensive, space-intensive | Water utilities, low energy loss |

| Wedge Meter | Sharp V-shaped wedge | Strong anti-clogging, for viscous fluids | Requires calibration, custom design | Slurry, particle-laden fluids |

| Averaging Pitot (Annubar) | Multiple pressure ports | Low pressure loss, easy to install | Lower accuracy, sensitive to flow profile | Steam, clean gas, large pipes |

3. System Components

A DP flow meter system typically includes:

Primary Element (Restriction Device): Generates ΔP.

Differential Pressure Transmitter: Converts ΔP, temperature, and pressure into standardized signals (e.g., 4–20 mA, HART, Modbus), with density compensation for gases/steam.

Display and Calculation Unit: Computes instantaneous and totalized flow; supports local display, remote communication, or integration into DCS.

4. Technical Characteristics

Advantages

High Versatility: Suitable for gases, liquids, steam under extreme conditions (–200°C to +850°C, 0–40 MPa).

Standardized Design: Complies with ISO 5167, GB/T 2624; standard designs do not require calibration.

Proven Technology: Widely accepted and field-proven.

Limitations

Pressure Loss: Notably high for orifice plates, increasing energy cost.

Limited Turn-down Ratio: Typically 3:1 to 5:1; proper sizing is crucial.

Installation Sensitivity: Requires long upstream/downstream straight pipe runs.

Media Sensitivity: Clogging risk with dirty fluids; requires density, viscosity compensation.

5. Installation Guidelines

Straight Pipe Requirements

Orifice Plate: ≥10D upstream (no elbows), ≥30D (with elbows), ≥5D downstream.

Venturi Tube: ≥10D upstream, ≥5D downstream.

Pressure Tapping Methods

Orifice: Corner taps, flange taps.

Venturi: D and D/2 taps.

Orientation

Horizontal: Side taps for liquids, top taps for gas.

Vertical: Flow must be upward.

Sealing and Centering

Gaskets must not protrude into flow; device must be coaxial with pipe.

6. Application Industries

Oil & Gas: Crude oil, refined products, natural gas, steam.

Power Generation: Boiler air, main steam, cooling water.

Metallurgy & Cement: Blast furnace gas, slurry, compressed air.

Water Utilities: Potable and irrigation water (Venturi recommended).

Energy Management: Industrial gases, steam flow measurement.

7. Maintenance and Troubleshooting

Routine Maintenance

Inspect pressure lines for blockages or leaks.

Drain condensate in gas service.

Calibrate transmitter zero, check signal stability.

Clean throttling elements periodically (e.g., blowback, offline cleaning).

Common Issues

| Symptom | Possible Causes |

|---|---|

| Low/unstable ΔP | Clogged tap lines, eroded elements, leaks |

| Zero shift | Transmitter drift, temperature/pressure effects |

| Poor accuracy | Short pipe runs, turbulent flow, low Re numbers |

8. Key Selection Considerations

Medium Characteristics:

Cleanliness, viscosity, corrosiveness → Material selection (e.g., 316L, Hastelloy).

Phase: gas, liquid, steam.

Process Conditions:

Pipe size (DN15–DN2000+), flow range, temperature, pressure.

Accuracy Requirements:

Orifice (±1%–2%), Nozzle (±0.5%–1%), Venturi (±0.5%).

Pressure Loss Constraints:

Use Venturi/Nozzle for low-loss applications.

Installation Space:

Consider required straight runs and maintenance access.

9. Comparison with Other Flow Meters

| Type | Advantages | Disadvantages | Typical Applications |

|---|---|---|---|

| DP Flow Meter | Widely applicable, standardized | High pressure loss, narrow turn-down | Multiphase and harsh fluids |

| Vortex Flow Meter | No moving parts, wide range | Sensitive to vibration, low Re accuracy | Clean liquids/gases (e.g., air, water) |

| Electromagnetic Meter | No pressure loss, for conductive liquids | Not suitable for non-conductive media | Wastewater, corrosive fluids |

| Ultrasonic Flow Meter | Non-invasive, ideal for large pipes | Accuracy affected by pipe condition | Water metering, large pipelines |

10. Development Trends

Smart Capabilities: Integrated temperature/pressure compensation, online diagnostics, wear detection, advanced signal processing for turn-down ratio >10:1.

Low Power & Wireless: Battery + wireless modules for remote locations (e.g., natural gas pipelines).

Custom Throttling Designs: Twin-wedge, hybrid elements for complex fluids.

Digital Verification: CFD simulation for optimized design and reduced calibration cost.

Conclusion

Differential pressure flow meters remain a cornerstone of industrial flow measurement due to their versatility, standardization, and reliability. Despite challenges such as pressure loss and installation constraints, they are ideal for multipurpose flow measurement across industries. With smart features and digital enhancements, their role will continue to evolve toward higher efficiency and intelligence.