Introduction

The differential pressure (DP) flowmeter is one of the oldest and most widely used flow measurement devices. Despite the emergence of advanced electronic flowmeters, such as electromagnetic and vortex flowmeters, the orifice flowmeter remains prevalent in various industries. This guide provides an in-depth understanding of orifice flowmeters, their working principles, components, installation, and maintenance practices.

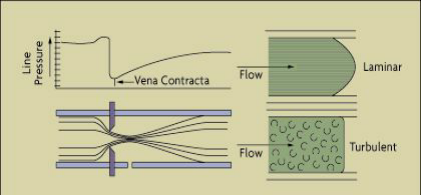

Principle of Operation

An orifice flowmeter operates based on the principle of flow restriction. When a fluid flows through a pipeline containing an orifice plate, the flow is constricted, causing a pressure drop across the plate. The differential pressure generated is directly proportional to the square of the flow rate, allowing flow measurement by monitoring the pressure difference.

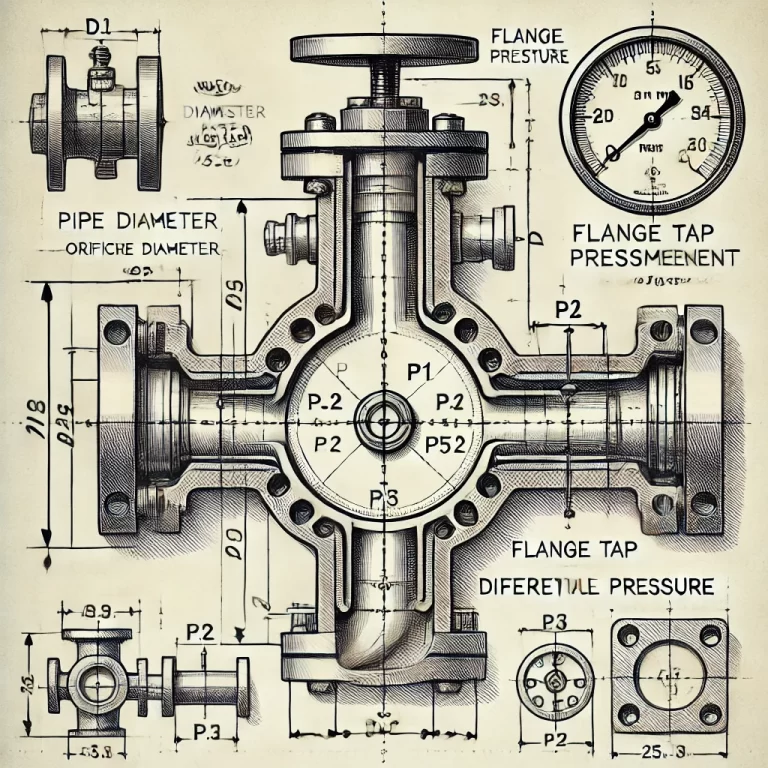

Components of an Orifice Flowmeter System

A typical orifice flowmeter system consists of the following key components:

Orifice Plate: A thin metal plate with a precisely machined hole at the center.

Pipeline: The conduit through which the fluid flows.

Differential Pressure Transmitter: Measures the pressure difference across the orifice plate.

Impulse Lines: Connect the pressure taps to the transmitter.

Standard Orifice Plates

Several types of standard orifice plates are commonly used, including:

Concentric Orifice Plate: The most widely used type with a central hole.

Eccentric Orifice Plate: Designed for measuring fluids containing solid particles.

Segmental Orifice Plate: Used for slurry and dirty fluid measurements.

Structure of a Standard Orifice Plate

A standard orifice plate is a circular metal disc with a sharp-edged hole at the center. The upstream side of the plate has a cylindrical opening, while the downstream side features a conical expansion. Key specifications include:

Plate Thickness: Typically ranges from 3 mm to 10 mm.

Conical Angle: Generally between 30° and 45°.

Edge Sharpness: Maintained to ensure minimal flow disturbances.

Operational Conditions

For accurate measurement, the following conditions must be met:

Full Pipe Flow: The fluid must completely fill the pipeline.

Stable Flow Profile: The flow should be steady and free of turbulence.

Single-phase Fluid: The fluid should not undergo phase changes.

No Debris Accumulation: Regular cleaning is required to prevent blockages.

Differential Pressure Transmitter

The differential pressure transmitter is a crucial component of the system, converting the pressure difference into an electrical signal (commonly 4-20 mA DC). Modern transmitters utilize capacitive sensing technology, providing high accuracy and long-term stability.

Working Principle

The transmitter consists of two chambers separated by a diaphragm filled with a transmission fluid (silicone or fluorocarbon oil). When pressure is applied, the diaphragm deflects, causing changes in capacitance, which are converted into electrical signals.

Common Issues and Solutions

High Output Readings

Causes:

Blocked impulse lines.

Electrical connection issues.

Solutions:

Inspect impulse lines for blockages or leaks.

Verify circuit connections and power supply.

Low or No Output

Causes:

Leaks in impulse lines.

Faulty electronic components.

Solutions:

Check for leaks and clear any obstructions.

Replace faulty components if necessary.

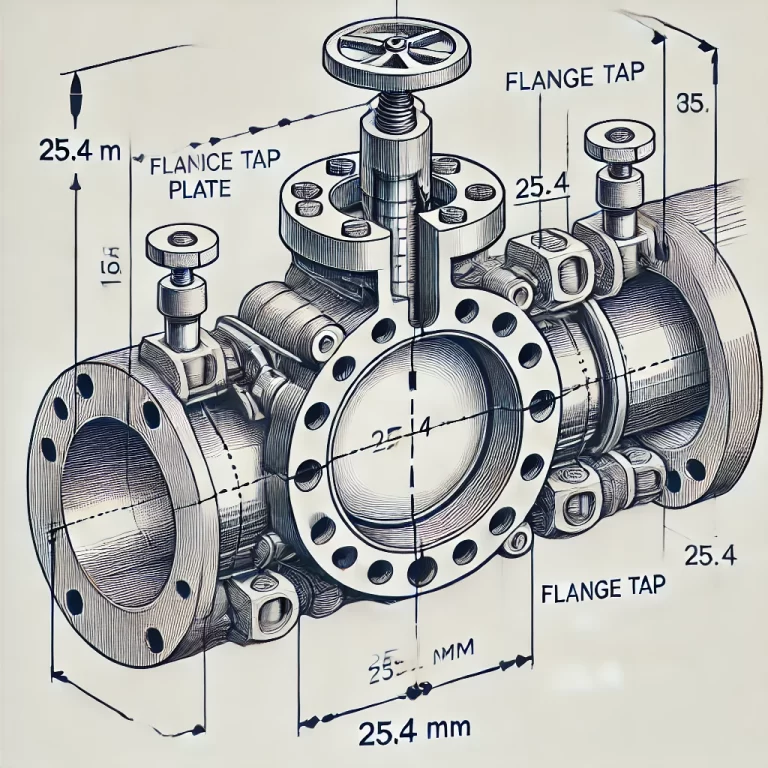

Installation Guidelines

Proper installation is critical for accurate flow measurement. The following best practices should be observed:

Orifice Plate Alignment:

Ensure the plate is centered and perpendicular to the pipeline.

The sharp edge of the orifice must face the flow direction.

Straight Pipe Requirements:

Sufficient straight pipe lengths are required upstream and downstream to avoid turbulence.

Reference installation manuals for specific pipe length recommendations.

Impulse Line Positioning:

For liquid flow measurement, impulse taps should be located at the lower half of the pipe.

For gas flow measurement, taps should be positioned at the top to avoid liquid accumulation.

Steam applications require condensate pots to protect the transmitter.

Three-Valve Manifold Installation:

A three-valve manifold should be installed near the transmitter for calibration and maintenance.

Proper startup and shutdown procedures must be followed to prevent damage.

Maintenance Practices

Regular maintenance ensures the longevity and accuracy of the orifice flowmeter system.

Routine Inspection Checklist

Visual Inspection:

Check for corrosion and wear on the orifice plate.

Inspect impulse lines for leaks or blockages.

Cleaning:

Regularly clean the orifice plate to remove debris and deposits.

Use appropriate cleaning solutions based on the fluid type.

Calibration:

Periodic calibration of the differential pressure transmitter to ensure measurement accuracy.

Seal Integrity:

Verify the integrity of gaskets and seals to prevent leaks.

Advantages and Limitations

Advantages

Simple and robust design.

Low installation and maintenance costs.

Standardized manufacturing ensures repeatability.

Suitable for a wide range of fluids (liquids, gases, steam).

Limitations

Pressure drop can lead to energy losses.

Susceptible to clogging with dirty or viscous fluids.

Requires regular maintenance to ensure accuracy.

Conclusion

Orifice flowmeters continue to be a reliable and cost-effective solution for flow measurement in various industrial applications. By understanding their working principles, installation requirements, and maintenance practices, operators can optimize performance and achieve accurate flow measurements. Proper adherence to guidelines will help maximize the lifespan and efficiency of the system.