Hose clamps (also known as clamps or hose clips) are essential components widely used in various industries, including automotive, plumbing, agricultural, and industrial systems, to secure hoses and piping. They provide tight sealing, reduce the risk of leakage, and maintain structural integrity. This article explores the different types of hose clamps, their common applications, and specific sizes to help you choose the right clamp for your project.

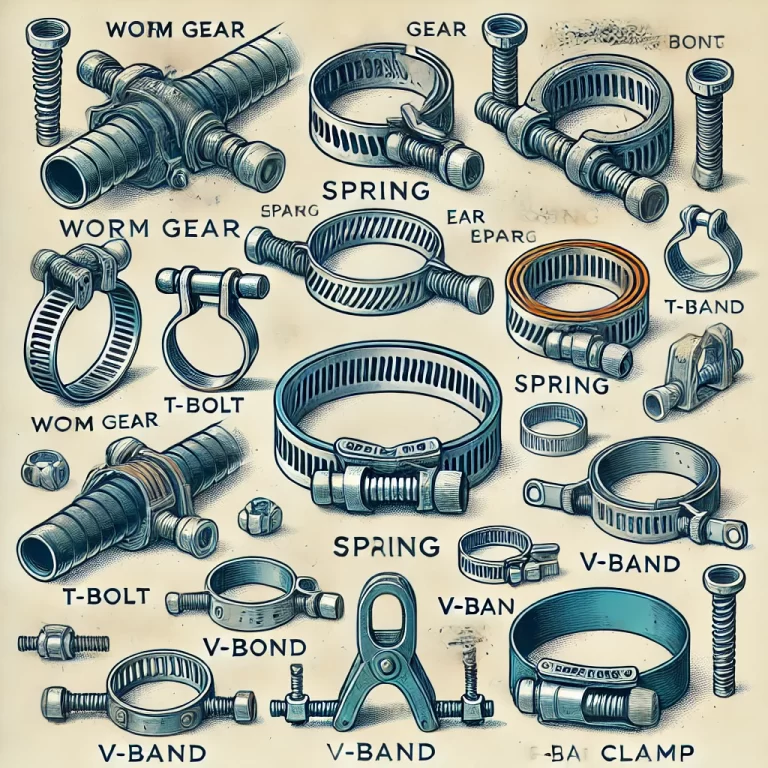

1. Types of Hose Clamps

There are several types of hose clamps, each designed for different applications and pipe materials. The following are the most commonly used types:

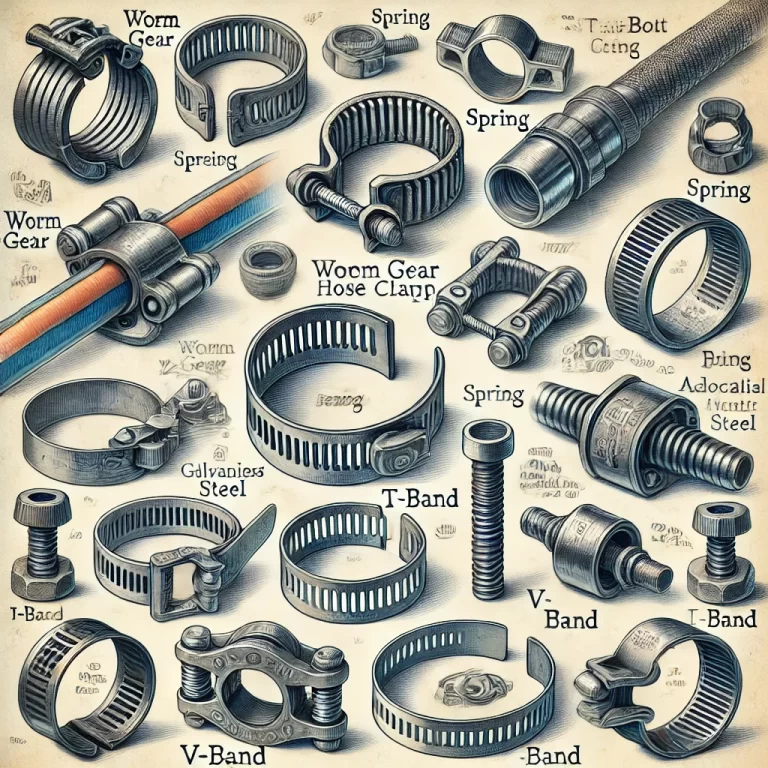

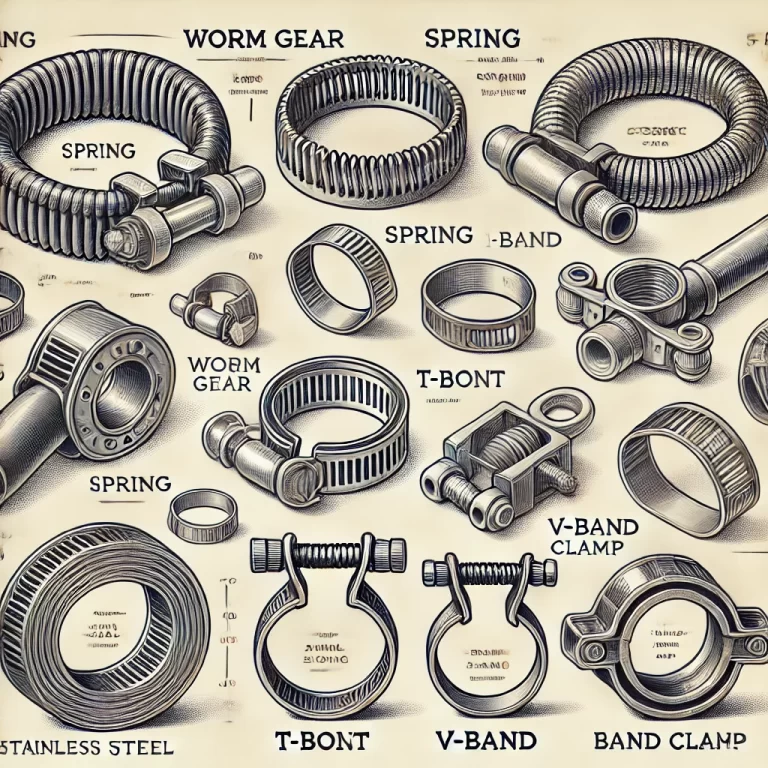

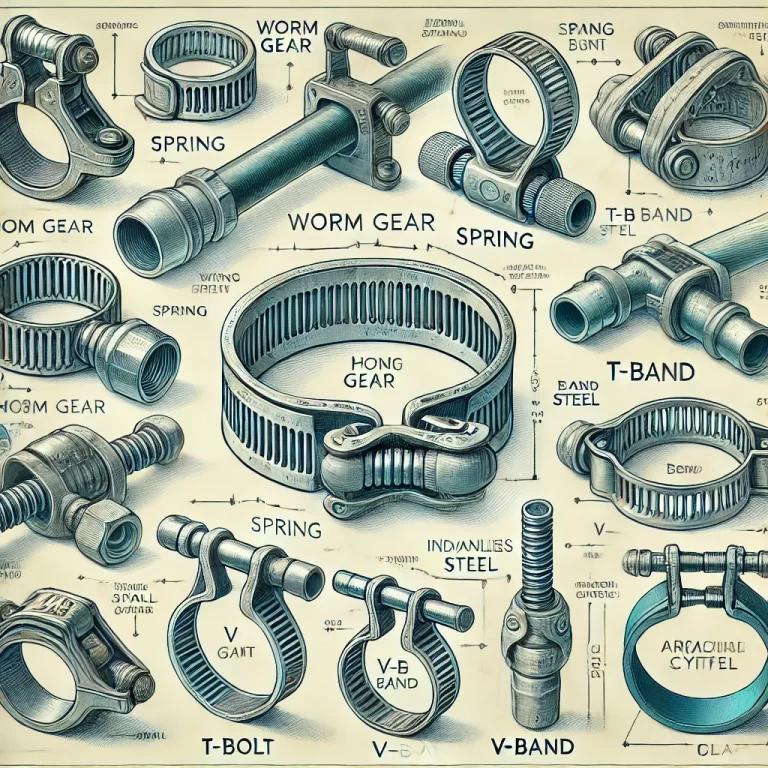

1.1 Worm Gear (Screw) Hose Clamp

- Design: This is one of the most widely used hose clamps. It features a metal band with a screw-threaded housing. By turning the screw, the band tightens or loosens, allowing for secure attachment.

- Application: Worm gear hose clamps are ideal for connecting hoses to pipes or fittings in vehicles (e.g., cooling systems, fuel lines) and household appliances such as washing machines and dishwashers.

- Material: Typically made of stainless steel or galvanized steel to resist corrosion.

- Common Sizes:

- Small: 8-12mm (hose diameter)

- Medium: 16-25mm

- Large: 30-45mm, with sizes available up to 100mm or more.

1.2 Spring Hose Clamp

- Design: Made from spring steel, this type uses its own elasticity to exert pressure on a hose, ensuring a firm grip. The clamp is applied by pinching the ends together with pliers and releasing them over the hose.

- Application: Spring hose clamps are used in low-pressure applications, such as automotive cooling systems and heating systems. They are especially favored in environments with temperature fluctuations, where materials tend to expand and contract.

- Material: Typically constructed from carbon steel or stainless steel.

- Common Sizes:

- Small: 12-16mm

- Medium: 16-20mm

- Large: 20-32mm

1.3 Ear (Oetiker) Clamp

- Design: This clamp has two small ears that are crimped with a tool to tighten it. Once applied, the clamp creates a consistent and leak-proof seal.

- Application: Ear clamps are often used in fuel lines, air hoses, and other fluid and gas systems in industries like automotive and plumbing. Their simple design ensures a reliable seal.

- Material: Usually made of stainless steel, offering good resistance to corrosion.

- Common Sizes:

- Small: 10-12mm

- Medium: 15-18mm

- Large: 18-21mm

1.4 T-Bolt Clamp

- Design: T-bolt clamps have a T-shaped bolt and nut that tighten the clamp around the hose with a more uniform pressure, providing high strength and security. These clamps are ideal for heavy-duty applications where traditional worm gear clamps may fail.

- Application: Used in high-pressure environments, such as turbocharger systems, agricultural machinery, and industrial pipelines. They are also suitable for large-diameter hoses.

- Material: Constructed from durable stainless steel or carbon steel.

- Common Sizes:

- Medium: 30-45mm

- Large: 50-70mm

- Extra Large: 90-120mm

1.5 V-Band Clamp

- Design: The V-band clamp consists of a V-shaped metal ring that applies uniform pressure around the hose or piping. This clamp type is often paired with a gasket for enhanced sealing.

- Application: It is used in high-pressure and high-temperature applications, such as exhaust systems, turbocharger connections, and pressure vessels.

- Material: Often made of high-temperature-resistant materials such as stainless steel.

- Common Sizes:

- Medium: 38mm

- Large: 51mm

- Extra Large: 89mm

1.6 Band Clamps (Strap Clamps)

- Design: Band clamps consist of a flexible steel band that wraps around the hose or object, tightened with a screw mechanism. They are commonly used for temporary or adjustable connections.

- Application: These clamps are useful in general-purpose applications such as irrigation, household plumbing, and even automotive systems. They are flexible and can be adjusted to various sizes.

- Material: Typically made of stainless steel or plastic for lower-pressure applications.

- Common Sizes:

- Small: 20-25mm

- Medium: 25-32mm

- Large: 32-50mm

| Clamp Type | Size Range (mm) | Suitable Hose Outer Diameter (mm) |

|---|---|---|

| Worm Gear Clamp | 8-12, 12-22, 25-40 | Small diameter hoses and pipes |

| Spring Hose Clamp | 12-16, 16-20 | Small to medium hose connections |

| Ear Clamp | 10-12, 18-21 | Fuel lines, air hoses, and small pipes |

| T-Bolt Clamp | 30-45, 50-70, 90-120 | High-pressure or large-diameter pipes |

| V-Band Clamp | 38, 51, 89 | High-temperature and high-pressure systems |

| Band Clamp | 20-25, 25-32, 32-50 | Plumbing, irrigation, and general use |

2. Applications of Hose Clamps

Hose clamps are indispensable in many industries due to their versatility and reliability. Below are some common applications:

2.1 Automotive Industry

Hose clamps are widely used in vehicle systems to secure hoses in place and prevent fluid leaks. They are commonly found in:

- Cooling systems (radiator hoses)

- Fuel lines (gasoline and diesel)

- Air conditioning systems

- Exhaust systems (using V-band clamps for high temperatures)

2.2 Plumbing and HVAC Systems

In residential and commercial plumbing systems, hose clamps secure pipes and tubing that carry water or air. They are used for:

- Water supply lines (e.g., washing machines, dishwashers)

- Drainage systems

- HVAC systems (heating and air conditioning ducts)

2.3 Industrial Applications

Industries that deal with high-pressure fluids or gases rely on heavy-duty clamps like T-bolt and V-band clamps. These are used in:

- Chemical plants (corrosive material transport)

- Oil and gas pipelines

- Food and beverage processing (to seal hoses in sanitary conditions)

2.4 Agricultural and Irrigation Systems

In agriculture, hose clamps are used in irrigation systems to secure hoses and pipes. Their applications include:

- Water distribution systems (securing hoses to sprinklers and water outlets)

- Fertilizer distribution lines

3. Choosing the Right Hose Clamp Size

Choosing the appropriate size is crucial for ensuring the hose clamp provides a proper seal and avoids damage. The clamp’s diameter should match the outer diameter (OD) of the hose, including the fitting or nipple it’s attached to. Most manufacturers provide size ranges for each type of clamp to accommodate various hose diameters.

For example:

- Worm Gear Clamp: If your hose’s OD is 20mm, select a clamp that fits a range of 16-25mm.

- Ear Clamp: If your hose has a diameter of 15mm, choose an ear clamp that fits 15-18mm.

- T-Bolt Clamp: For high-pressure hoses with a 50mm diameter, choose a clamp in the 50-70mm range.

4. Material Considerations

Selecting the right material for your hose clamp is as important as selecting the size. The clamp material should be resistant to corrosion, chemicals, and environmental factors. Stainless steel is a popular choice for its corrosion resistance, while galvanized steel may be used in less demanding environments. In specific situations, plastic clamps may be used for lower-pressure systems.

Conclusion

Hose clamps are essential tools in ensuring the safety and efficiency of piping systems across industries. Understanding the different types, applications, and specific sizes will help you make informed decisions when choosing the right hose clamp for your needs. By selecting the appropriate clamp type, material, and size, you can ensure a secure and reliable connection for any hose or piping application.