Thermocouples are essential temperature sensors widely used in industrial applications. They work by generating a voltage that corresponds to temperature changes. Thermocouples can be classified into several categories based on different criteria. This article provides a comprehensive overview of the various classification methods, including material types, structure, installation, and measurement forms, helping readers understand their applications and selection criteria.

1. Classification by Electrode Materials

Thermocouples can be categorized based on the materials used for the electrodes. The most common types are:

Precious Metal Thermocouples (Platinum-Rhodium Alloys)

R-Type (Platinum-Rhodium 13% – Platinum): This thermocouple is suitable for high-temperature applications, ranging from 0°C to 1450°C. It offers high accuracy, excellent stability, and is ideal for high-precision measurements.

S-Type (Platinum-Rhodium 10% – Platinum): It is also used in high-temperature environments (0°C to 1450°C), with a long-term operating temperature of up to 1300°C, and a short-term limit of 1600°C. It is known for its stable performance and is commonly used in standard instruments.

B-Type (Platinum-Rhodium 30% – Platinum-Rhodium 6%): Designed for extremely high temperatures (0°C to 1700°C), the B-type thermocouple has a minimal thermoelectric voltage and is used in ultra-high-temperature measurements.

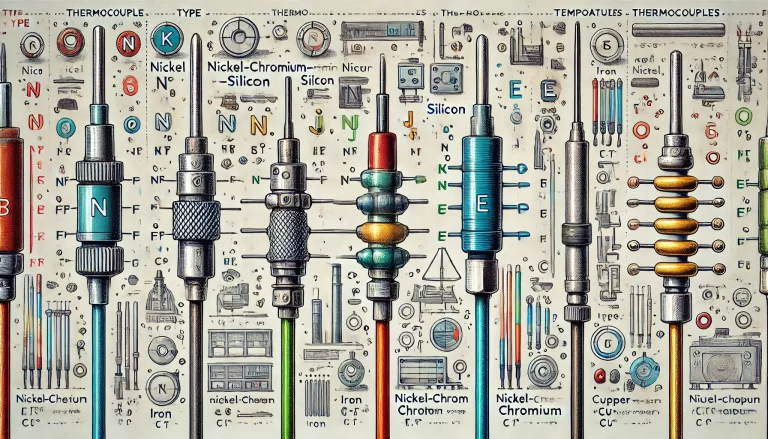

Base Metal Thermocouples

K-Type (Nickel-Chromium – Nickel-Silicon/Nickel-Aluminum): This thermocouple has a temperature range of -200°C to 1250°C (short-term up to 1372°C). It features excellent linearity, strong oxidation resistance, and high stability. However, it has lower accuracy at low temperatures and is prone to corrosion in reducing environments.

N-Type (Nickel-Chromium-Silicon – Nickel-Silicon-Magnesium): With a range of -270°C to 1300°C, the N-type thermocouple is an improvement over the K-type, offering better stability in the 300°C to 800°C range and superior oxidation resistance and high-temperature stability.

J-Type (Iron – Copper-Nickel/Constantan): Ideal for temperatures ranging from 0°C to 750°C, the J-type thermocouple is highly sensitive and cost-effective but prone to oxidation, limiting its use to non-oxidizing environments.

E-Type (Nickel-Chromium – Copper-Nickel/Constantan): This thermocouple offers the highest sensitivity among standard thermocouples, with a temperature range of -200°C to 900°C. Its large thermoelectric voltage makes it suitable for vacuum and inert gas environments.

T-Type (Copper – Copper-Nickel/Constantan): With a temperature range of -200°C to 350°C, the T-type thermocouple excels in low-temperature applications, offering good stability and high accuracy. However, copper is prone to oxidation at higher temperatures.

2. Classification by Structure

Thermocouples can be categorized based on their structural forms, each designed for different applications and environmental conditions:

General Thermocouple

A typical thermocouple consists of a thermoelement, an insulating tube, a protective sheath, a junction box, and terminals. The insulating tube prevents short circuits between the thermoelements, and the material is selected based on the temperature range. The protective sheath safeguards the thermoelements from chemical corrosion and mechanical damage. However, adding a protective sheath can slow down the thermocouple’s dynamic response.

Armored Thermocouple

This type uses a metal sheath, ceramic insulation, and thermoelements. The outer diameter generally ranges from 2 to 8 mm. It is filled with magnesium oxide between the thermoelements and the sheath for insulation. Armored thermocouples are highly durable and resistant to vibration and mechanical shock, offering fast thermal response and excellent performance in complex environments like measuring temperatures in curved pipes.

Thin Film Thermocouple

These thermocouples utilize thin-film technology to integrate thermoelement materials onto the surface of the measured object. They are ideal for micro-space and quick-response applications, providing millisecond-level response times (e.g., ≤50 ms). Thin-film thermocouples are known for their high accuracy and minimal impact on the thermal characteristics of the measured surface.

Multipoint Thermocouple

This thermocouple type consists of several thermocouples of different lengths assembled using a porous insulating tube. It is commonly used in industrial processes, such as measuring temperatures at different heights in reactors or in applications like hydrogenation reactors.

Explosion-Proof Thermocouple

Explosion-proof thermocouples are similar to general thermocouples but feature explosion-proof junction boxes for use in hazardous environments. These thermocouples are required in explosive or flammable areas to prevent ignition.

Surface-Mount Thermocouple

Used to measure the surface temperature of objects, surface-mount thermocouples are mechanically fixed or adhered to the measured surface. While they provide fast response times, they are more susceptible to heat transfer influences from the surface.

Wear-Resistant Cutting Thermocouple

Designed for harsh environments with high wear and corrosion, these thermocouples are commonly used in refineries, chemical plants, and power plants. The protective head is spray-welded with a nickel-tungsten carbide (Ni+WC35) coating, increasing its hardness and wear resistance.

Probe Thermocouple

This type consists of a probe and cable. Depending on the application, the probe can be designed in various forms, such as probe-type, patch-type, screw-type, or threaded for fixed installations.

3. Classification by International Standards

The International Electrotechnical Commission (IEC) categorizes thermocouples into two broad groups: standardized and non-standardized.

Standardized Thermocouples

Standard thermocouples have a unified temperature conversion table and interchangeability. IEC 60584 defines eight types of standardized thermocouples:

- Precious Metal Thermocouples: S, R, B

- Base Metal Thermocouples: K, N, E, J, T

Since 1988, China has adopted IEC standards and uses these thermocouples in industrial applications.

Non-Standardized Thermocouples

These thermocouples are designed for specific applications and do not have a unified temperature conversion table. Examples include:

Tungsten-Rhenium Series (W-Re3/W-Re25): Suitable for temperatures up to 2800°C in inert or vacuum environments but prone to oxidation in oxygen-rich conditions.

Platinum-Rhodium High-Temperature Thermocouples (e.g., PtRh20-PtRh5): Ideal for extremely high temperatures (above 1800°C) and have excellent thermal shock resistance.

Iridium-Rhodium Thermocouples (e.g., Ir-Rh): Used for ultra-high-temperature measurements (above 2000°C) in vacuum or inert environments.

4. Classification by Installation Method

Thermocouples can also be categorized by their installation methods, each suited to specific measurement environments:

- Non-Fixed Type: Used for temporary or mobile measurements.

- Threaded, Flanged, or Movable Flanged Types: Suitable for fixed installations in industrial settings.

5. Classification by Measurement End Forms

Thermocouples can be further classified based on the form of their measurement end:

Sheath Type: In this type, the thermocouple junction is connected to the probe wall, allowing for rapid heat transfer. However, it is more susceptible to electromagnetic interference.

Insulated Type: The thermocouple junction is separated from the probe wall, offering slower response times but providing electrical isolation and strong resistance to electromagnetic interference.

Exposed End Type: The thermocouple junction is exposed to the surrounding environment, providing the best response times but limited to dry, non-corrosive, and non-pressurized applications.

Conclusion

Selecting the right thermocouple depends on various factors, including the temperature range, accuracy requirements, response speed, environmental conditions (oxidizing/reducing, corrosive, vacuum, etc.), explosion-proof requirements, and cost. By understanding the different classification methods, users can better determine the thermocouple best suited for their specific application needs.