In industrial production processes, float level indicators are commonly used instruments for measuring liquid levels. Accurate readings are critical for stable operations, and any abnormalities in level indication can lead to production issues and quality control problems. This article explores the possible causes of abnormal float level indicator readings and provides practical case studies to highlight solutions.

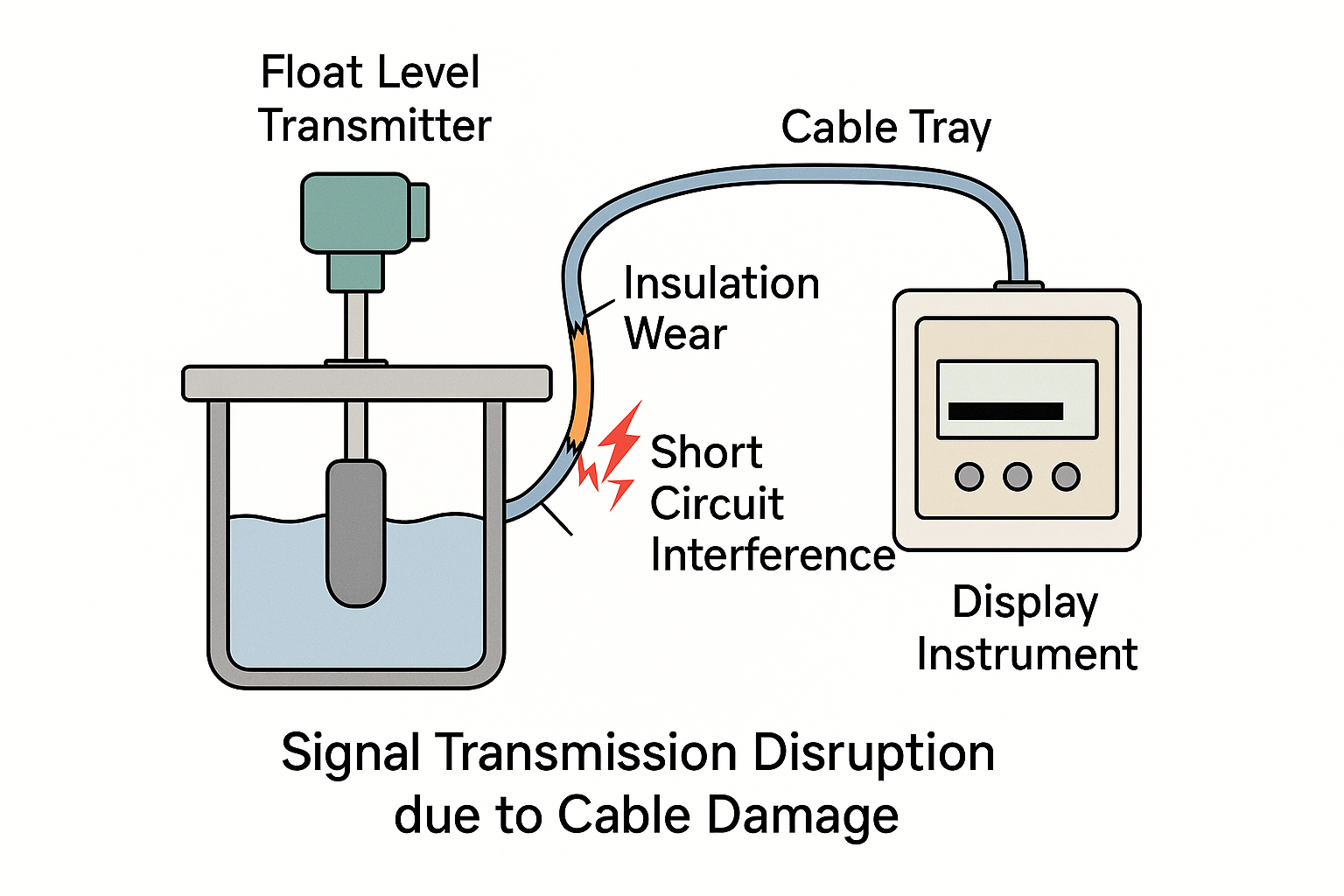

1. Incorrect Input Signals to the Display Instrument

If the display instrument receives inaccurate input signals, it directly results in abnormal level readings. This issue often arises from problems in the signal transmission line, such as damage, short circuits, or open circuits. For instance, in a chemical manufacturing plant, the float level indicator’s display instrument suddenly showed significant fluctuations in readings. Upon investigation, it was discovered that the signal cable connecting the float level transmitter to the display instrument was damaged at a corner of the cable tray due to long-term mechanical friction. This caused signal interference and occasional short circuits. To resolve this, the damaged section of the cable was repaired, ensuring stable and accurate signal transmission.

2. DCS Control System Interface Signal Issues

In systems controlled by a Distributed Control System (DCS), interface signal issues are common causes of abnormal level readings. DCS communicates with the float level indicator via specific interfaces, and any failure in signal conversion or transmission at these interfaces can result in inaccurate readings. A major refinery experienced discrepancies between the DCS display and the actual level indicated by the float level indicator. Upon investigation, the interface module responsible for receiving the float level signal in the DCS system was found to be malfunctioning, causing signal loss or errors during conversion and transmission. The solution involved checking and repairing the interface module, as well as recalibrating the communication parameters to ensure accurate signal reception by the DCS.

3. Inaccurate Zero Position of the Float Level Indicator

The zero position of the float level indicator can also cause abnormal readings. Over time, accumulated impurities or dirt inside the float can shift its initial position, leading to inaccurate zero calibration. For example, in a power plant’s boiler drum level measurement system, the float level indicator consistently indicated a higher level than the actual liquid level. After inspection, it was found that impurities in the boiler water had accumulated inside the float, causing a shift in the zero position. By following standard procedures to flush out the float and recalibrate the zero position, the indicator’s accuracy was restored.

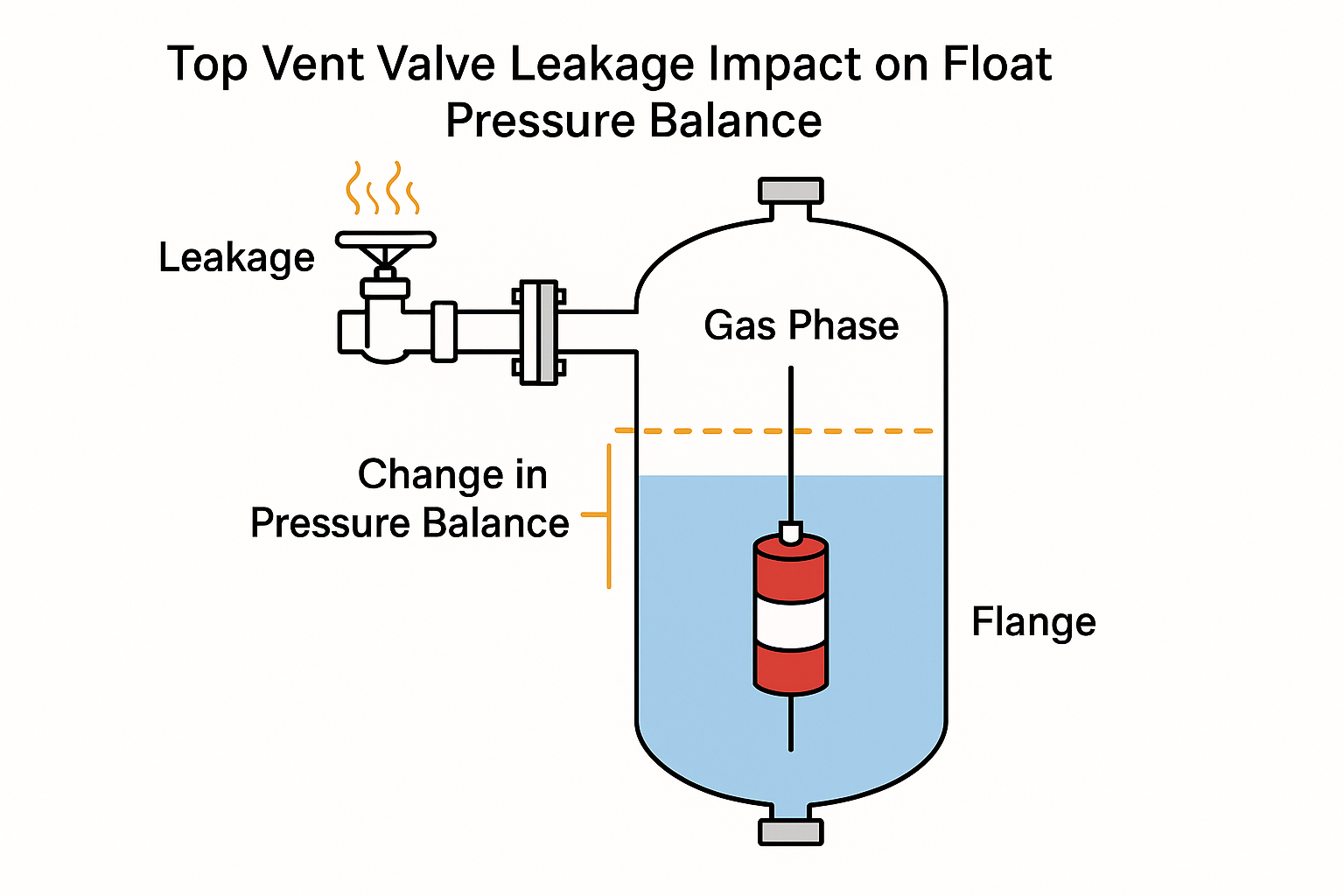

4. Leakage at the Top Vent Valve or Gas Phase Flange

If there is leakage at the top vent valve or gas phase flange of the float level indicator, it can alter the pressure environment around the float, impacting the measurement accuracy. At a petrochemical company’s raw material tank, a float level indicator displayed frequent and inaccurate readings. After on-site inspection, it was found that the vent valve’s sealing gasket was degraded, causing slight leakage. This disrupted the gas phase pressure above the float, affecting the buoyancy force on the float and leading to abnormal readings. Replacing the sealing gasket and checking the gas phase flange for leaks restored proper functioning of the float level indicator.

5. False Readings in Glass Level Indicators

False readings in glass level indicators may occur due to blockages in the pressure tapping valve, preventing normal fluid flow, or leakage in the top vent valve, which affects pressure balance inside the level indicator. For example, in a fertilizer plant’s liquid ammonia storage tank, the glass level indicator showed readings significantly different from those of the float level indicator. Upon inspection, it was found that the pressure tapping valve was blocked by crystallized ammonia salts, preventing fluid flow into the level indicator. After cleaning the tapping valve, the glass level indicator’s readings aligned with the float level indicator.

6. Significant Changes in Process Medium Density

Significant changes in the density of the process medium can also impact the accuracy of float level indicator readings. Float level indicators operate based on Archimedes’ principle, and the measurement is directly affected by the medium’s density. A decrease in density can reduce the buoyancy force on the float, causing the level to appear higher than it actually is. For example, in a pharmaceutical plant, a change in the composition of materials in a reaction kettle led to a reduction in the medium’s density. The float level indicator displayed a higher level than the actual level, as the reduced density led to lower buoyancy force on the float. In such cases, the float level indicator’s range and parameters must be recalculated and adjusted according to the new medium density to ensure accurate readings.

Conclusion

The causes of abnormal readings in float level indicators are multifaceted, involving issues with the instrument itself, signal transmission, installation, maintenance, and the characteristics of the process medium. In practice, when facing abnormal readings, it’s essential to systematically investigate and consider all potential causes. By combining theoretical analysis with practical case studies, this article provides useful insights into troubleshooting float level indicator issues and ensuring reliable operation to maintain stable and safe industrial production.