Bimetallic thermometers are widely used in industrial temperature measurement due to their simplicity, reliability, and independence from power supply. However, their accuracy and service life depend heavily on proper daily maintenance. This guide outlines a comprehensive maintenance strategy across four key dimensions: cleaning, inspection, calibration, and environmental protection.

1. Cleaning and Component Inspection

1.1 Surface Cleaning

Use a soft brush to remove dust from the dial. For greasy or oily stains, gently wipe with a cloth dampened in high-purity alcohol. Avoid abrasive tools such as steel wool or any chlorine-based cleaners to prevent scratching the glass or corroding the casing.

1.2 Critical Component Checks

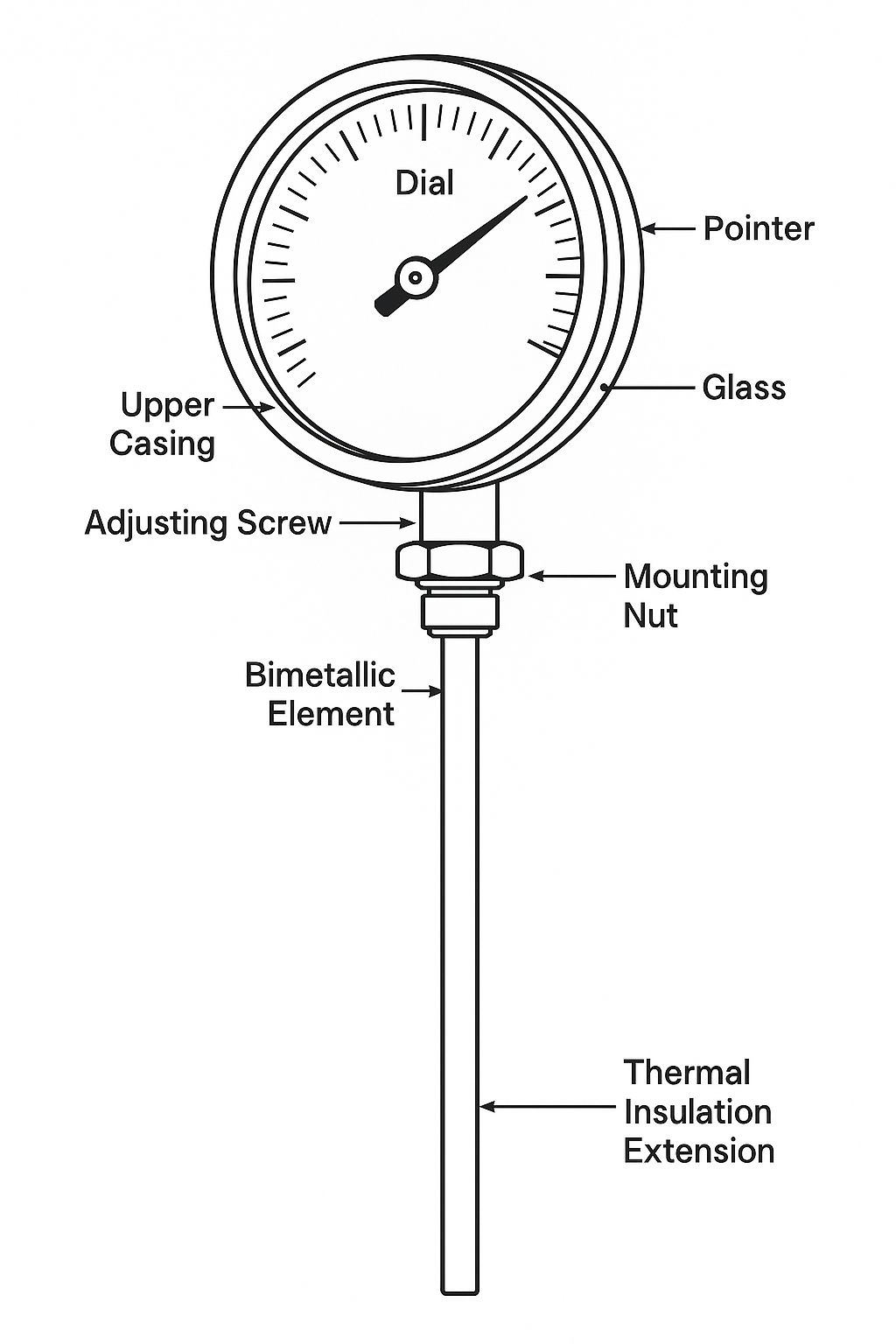

Pointer Alignment: Rotate the dial and observe if the pointer consistently stays 1–2 mm above the scale plate. If deviation exceeds 0.5 mm, realignment is required.

Tightness of Fasteners: Turn the mounting nut clockwise until snug. If you detect wobbling or stripped threads, replace damaged components immediately.

Seal Condition: Gently press the waterproof rubber ring. If it becomes hardened, cracked, or deformed, replace it with a new seal to maintain environmental protection.

2. Accuracy Calibration

2.1 Zero Point Check

Submerge the thermometer in an ice-water mixture for 30 minutes. The pointer should point close to 0°C (32°F). If deviation is significant, adjust the zeroing screw (turn clockwise to increase, counterclockwise to decrease).

2.2 Full-Scale Calibration

Place the thermometer in its maximum rated temperature environment (e.g., 200°C / 392°F), and compare with a standard thermometer. If the reading is off, loosen the pointer nut and reposition it precisely on the scale after temperature stabilizes.

2.3 Mid-Scale Validation

Measure a midpoint temperature (e.g., 100°C / 212°F). If consistent over- or under-reading is observed, this could indicate bimetallic element aging. Record the error and apply reading compensation as needed.

3. Special Environmental Maintenance

3.1 High-Vibration Areas

Use rubber dampers and ensure firm installation.

In high-vibration conditions, calibrate monthly to prevent long-term drift.

3.2 Corrosive Environments

Clean the thermometer housing weekly.

Use stainless steel for general corrosion, or special alloy cases for highly corrosive media.

Reapply protective coatings if peeling is observed.

3.3 High-Temperature Conditions

If the dial body is exposed to temperatures above 60°C (140°F), install a thermal insulation extension stem to avoid sticking or mechanical distortion due to heat buildup.

4. Maintenance During Storage or Downtime

Always power down and document mounting position before removing the instrument.

Store in a dry, ventilated space with temperatures between 10–30°C (50–86°F) and low humidity.

Avoid storing with volatile chemicals.

Once the pointer returns to zero, fix it with a rubber band to prevent movement during transport.

💡 Pro Tip:

By following this step-by-step maintenance plan, you can significantly extend the life of your bimetallic thermometer, maintain its measurement accuracy, and reduce unexpected failures on-site.