Ultrasonic flow meters are widely used for accurate measurement of fluid flow in pipelines. The two primary installation methods are the Z-method and the V-method. Each has unique characteristics, making them suitable for different pipeline conditions and diameters. This article explores their features, advantages, and installation considerations in detail.

1. Overview of Installation Methods

V-Method Installation

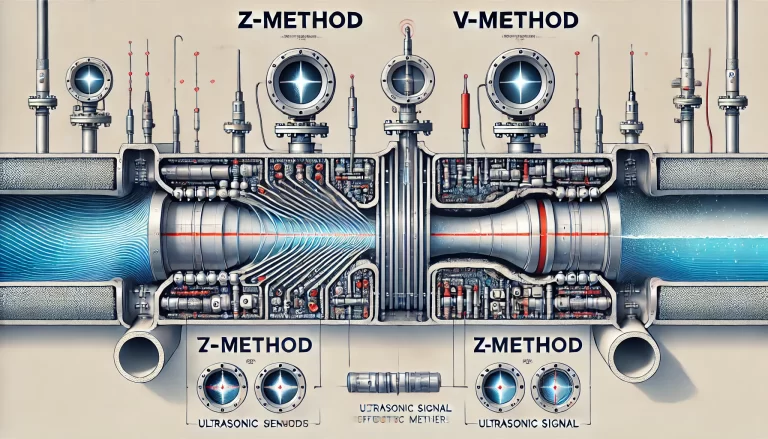

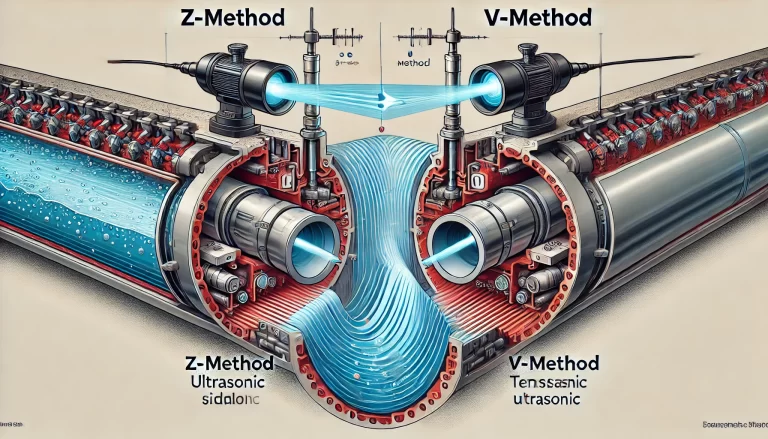

The V-method involves aligning two sensors horizontally, with their centerlines parallel to the pipeline’s axis. The ultrasonic signal reflects off the pipe wall during transmission, traveling along a longer path.

Z-Method Installation

The Z-method positions the sensors directly across from each other on opposite sides of the pipeline. The ultrasonic signal travels in a straight line through the medium, minimizing signal attenuation.

2. Applicability and Use Cases

V-Method

Pipe Diameter: Ideal for smaller pipelines, typically ranging from DN15 to DN200. In some cases, it can accommodate up to DN400.

Applications: Preferred for low-flow velocities and low-noise environments where precision is paramount.

Z-Method

Pipe Diameter: Suited for larger pipelines, generally from DN200 to DN6000. Also effective for smaller diameters under challenging conditions (e.g., high turbidity or heavy scaling inside the pipeline).

Applications: Ideal for scenarios requiring high signal quality, such as pipelines with impurities, bubbles, or significant scaling.

3. Features and Installation Characteristics

V-Method Characteristics

Sensor Alignment: Sensors are horizontally aligned, and the signal reflects off the pipe wall before reaching the receiver.

Signal Path: A longer transmission path due to wall reflection.

Ease of Installation: Quick and straightforward, requiring no pipe disassembly.

Environmental Suitability: Effective in low-flow and clean pipeline conditions.

Limitations: Signal strength may weaken due to rough pipe walls, scaling, or suspended particles, leading to potential accuracy issues.

Z-Method Characteristics

Sensor Alignment: Sensors are installed directly opposite each other on the same axial plane.

Signal Path: A direct, single-path transmission through the medium (no reflection).

Signal Strength: Higher signal intensity with minimal attenuation.

Precision: High accuracy in complex environments, such as turbulent or contaminated fluid conditions.

Installation Complexity: More demanding, requiring precise sensor alignment.

Cost Implications: Higher installation costs due to stricter alignment requirements and potentially more preparation time.

4. Advantages and Disadvantages

V-Method

Advantages:

Simpler and faster to install.

Non-invasive, with no need for pipe modifications.

Suitable for clean pipelines and small diameters.

Disadvantages:

Lower signal strength.

Susceptible to signal interference from internal pipe conditions.

Z-Method

Advantages:

High signal strength and measurement precision.

Effective in challenging environments, such as scaled or contaminated pipes.

Disadvantages:

Requires meticulous sensor alignment.

Higher installation costs and complexity.

5. Installation Guidelines and Best Practices

Pipeline Conditions

Avoid areas with strong magnetic fields, vibrations, or eddy currents.

Ensure the pipeline is fully filled with fluid and that flow is stable.

Sensor Placement

For horizontal pipelines, install sensors at the midpoint of the pipe’s height to avoid bubbles (at the top) or sediment (at the bottom).

Surface Preparation

Clean the pipe surface thoroughly to remove paint, rust, or debris.

Ensure tight contact between the sensor and the pipe.

Signal Quality Management

For weak V-method signals, switch to the Z-method for stronger signal transmission.

Use coupling agents to enhance signal transmission and minimize losses.

6. Additional Recommendations

Use Case Analysis: Conduct a site survey to determine the most suitable installation method based on pipeline size, condition, and flow characteristics.

Quality Assurance: Verify sensor alignment during and after installation using alignment tools.

Regular Maintenance: Periodically inspect sensors and pipe conditions to ensure consistent performance.

7. Conclusion

Choosing between the Z-method and V-method for ultrasonic flow meter installation depends on pipeline size, fluid conditions, and measurement accuracy requirements. The V-method offers ease of installation and is optimal for small, clean pipelines. In contrast, the Z-method provides higher precision and reliability for larger or more challenging pipelines. Proper planning, installation, and maintenance are crucial to achieving accurate and reliable flow measurement.