1. Basic Concept Comparison

| Item | Spray-Coated PTFE | Sintered PTFE |

|---|---|---|

| Principle | PTFE dispersion liquid or powder is sprayed onto the metal surface to form a coating. | PTFE powder is fused and sintered at high temperatures to form a solid (either whole or as a coating). |

| Base Material | Metal substrates (steel, aluminum, stainless steel, etc.) | Can be made from whole PTFE products (rod, plate, tube) or a PTFE coating on a substrate. |

| Processing Temperature | Typically 350–400°C to melt PTFE and form a film. | 370–400°C to melt and cool the PTFE. |

| Coating Thickness | Usually 20–100 μm (micron level) | Can reach 0.5–10 mm or even thicker. |

| Surface Characteristics | Smooth, low friction, corrosion-resistant, easy to clean | Excellent chemical resistance, high mechanical strength, pressure-resistant. |

| Typical Applications | Mold anti-stick, food machinery coatings, bolt corrosion protection, rail sliding layers | Chemical linings, sealing gaskets, bearing bushings, internal tubes. |

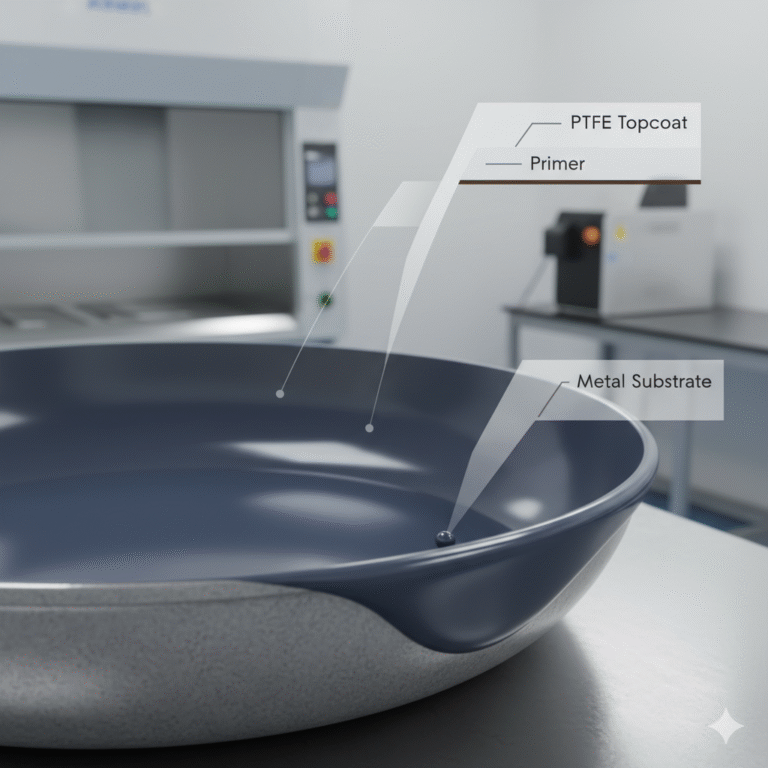

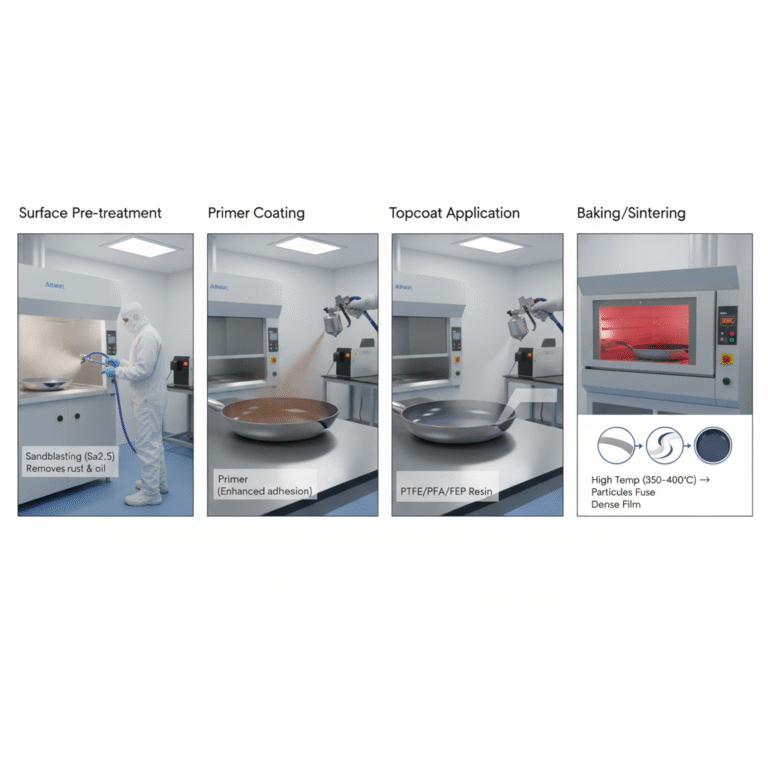

2. Detailed Process of Spray-Coated PTFE

1. Process Flow

Surface Pre-treatment

Purpose: Enhance coating adhesion.

Method: Sandblasting (Sa2.5 grade) or chemical treatment to remove rust and oil.Primer Coating

Contains modified resins to improve bonding with the metal.Topcoat Application

PTFE, PFA, or FEP resin is sprayed.Baking/Sintering

Heated to 350–400°C, where PTFE particles melt and fuse to form a continuous film.

2. Film Formation Mechanism

High temperatures melt the PTFE → Particles merge → Cooling forms a dense, non-stick coating.

3. Key Features

Advantages:

Extremely low friction coefficient (0.04–0.10)

Excellent acid and alkali resistance, high-temperature tolerance (-180 to +260°C)

Excellent non-stick properties (e.g., frying pans, molds)

Multiple layers can be applied in various colors.

Disadvantages:

Thin coating, not suitable for wear or pressure-bearing environments.

Adhesion depends on the quality of substrate treatment.

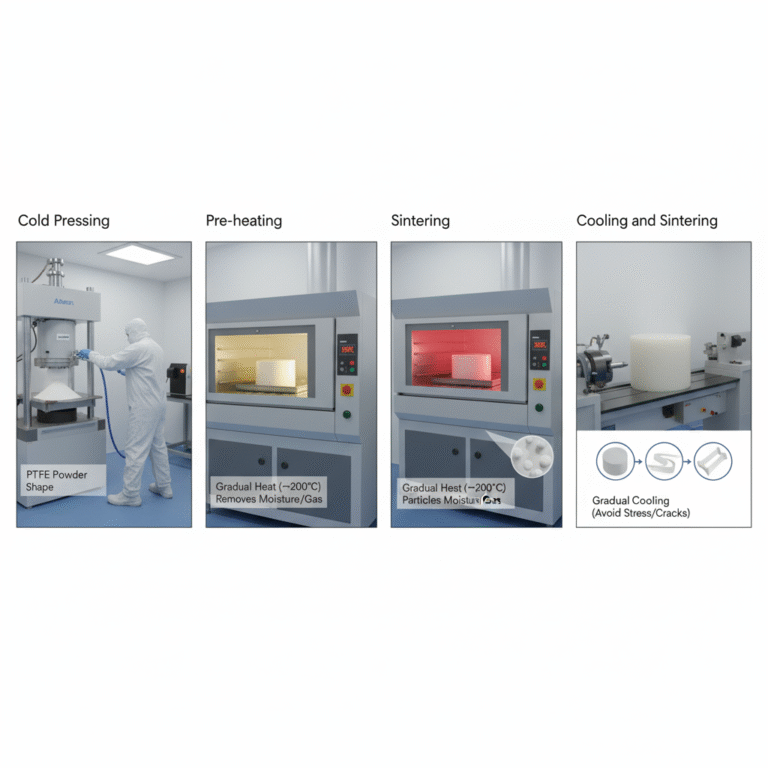

3. Detailed Process of Sintered PTFE

1. Process Flow (For Solid Parts)

Cold Pressing

Compress PTFE powder into the desired shape (rod blanks, plate blanks, or internal tube blanks).Degreasing and Pre-heating

Gradually heat up to approximately 200°C to remove residual moisture and gas.Sintering

Heat to 360–380°C (above the melting point of 327°C), allowing PTFE particles to melt and fuse.Cooling and Shaping

Gradually cool to avoid internal stress or cracks.

2. Sintered Coating Process (e.g., Steel-lined PTFE Tubes)

PTFE powder or preformed film is applied to the metal substrate; the whole assembly is sintered.

The molten PTFE bonds physically (no chemical bond) with the metal.

3. Key Features

Advantages:

Thick coatings with excellent wear and pressure resistance.

Extremely strong chemical resistance (can withstand almost all chemical agents).

Used for chemical equipment linings, corrosion-resistant pipelines, valve seats, and sealing gaskets.

Disadvantages:

Longer processing time and higher cost.

Requires advanced equipment (large sintering furnace).

Lacks strong chemical bonding to metals; only mechanical adhesion.

4. Performance Comparison Summary

| Performance Item | Spray-Coated PTFE | Sintered PTFE |

|---|---|---|

| Thickness | Thin (20–100 μm) | Thick (0.5–10 mm) |

| Adhesion Method | Spray + Baking/Sintering | Pressing + Sintering (Mechanical Bond) |

| Wear Resistance | Moderate | Excellent |

| Corrosion Resistance | Excellent | Superior |

| Cost | Relatively Low | Relatively High |

| Operating Temperature | ≤260°C | ≤260°C (Same as above) |

| Surface Finish | Very smooth | Depends on molding or polishing |

| Application Fields | Molds, food machinery, anti-corrosion bolts | Chemical pipelines, reactors, sealing components |

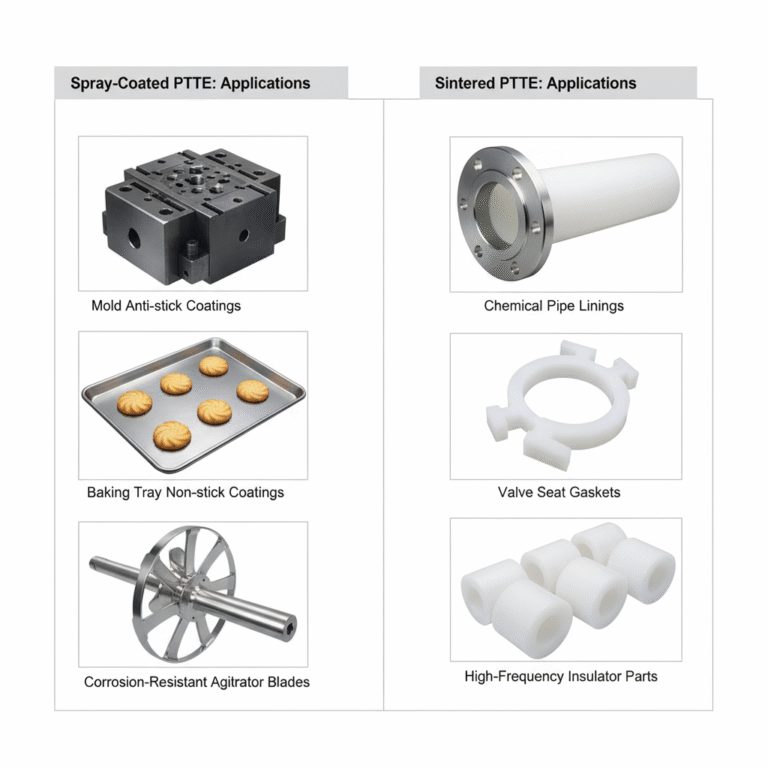

5. Application Examples

| Industry | Spray-Coated PTFE | Sintered PTFE |

|---|---|---|

| Food Machinery | Mold anti-stick coatings, baking tray non-stick coatings | Stainless steel-lined PTFE barrels |

| Chemical Equipment | Corrosion-resistant coatings on agitator blades | Reactor linings, valve seat bushings |

| Pharmaceuticals | Non-stick molds, material conveyors | Pipe linings, anti-corrosion gaskets |

| Electrical Industry | Insulation, anti-stick coatings | High-frequency insulator parts, lining tubes |

6. Simplified Summary (Layman’s Version)

Spray-Coated PTFE: “It’s like putting a non-stick coat on metal.” Thin, smooth, low friction.

Sintered PTFE: “It’s like making a solid piece from PTFE itself.” Thick, corrosion-resistant, strong.