1. Introduction to Common Stainless Steels (201, 202, 301, 304, 316)

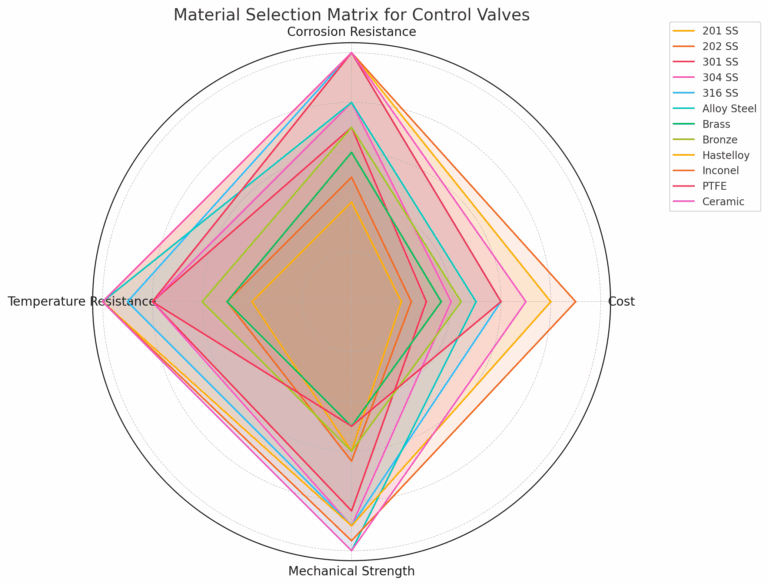

Stainless steels are widely used in industrial valve applications due to their corrosion resistance, strength, and thermal stability. Among them, grades 201, 202, 301, 304, and 316 represent the most commonly used options. The selection depends on environmental conditions, mechanical demands, and cost-performance tradeoffs.

| Grade | Density (g/cm³) | Thermal Conductivity (W/m·K at 100°C) | Thermal Expansion (20-100°C, µ10^-6/K) | Electrical Resistivity (Ω·mm²/m at 20°C) |

|---|---|---|---|---|

| 202 | 7.74 | 16.3 | 15.5 | 0.65 |

| 304 | 7.93 | 16.3 | 16.0 | 0.73 |

| 316 | 7.98 | 20.5 | 16.0 | 0.75 |

Key Differences:

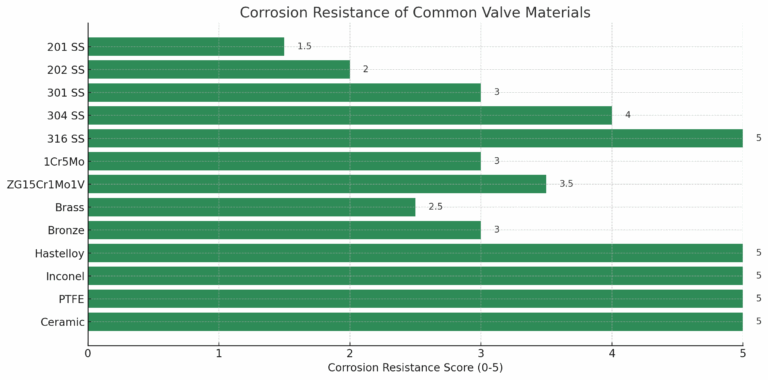

304: Widely used, excellent corrosion resistance, suitable for food-grade and chemical environments.

316: Enhanced with Mo, best for marine and chloride-rich environments.

201/202: Lower cost alternatives, limited corrosion resistance.

301: Good strength and heat resistance, used for springs and structural components.

2. Magnetic Properties

Austenitic stainless steels (e.g., 304, 316) are generally non-magnetic.

Martensitic and ferritic stainless steels (e.g., 410, 430) are magnetic.

Cold working can introduce magnetic properties even in austenitic steels.

3. Rusting in Stainless Steels

Despite their name, stainless steels can rust under:

Long-term exposure to saline or humid environments.

Surface contamination with iron particles.

Improper cleaning or chemical exposure.

4. Application in Control Valves

4.1 Stainless Steel Applications

| Grade | Performance Summary | Valve Component Examples | Typical Applications |

| 201 | Low Ni, lower corrosion resistance | Body of low-cost indoor valves | Clean water, air in mild conditions |

| 202 | Moderate corrosion resistance | Light-duty auxiliary valves | Food processing, auxiliary chemicals |

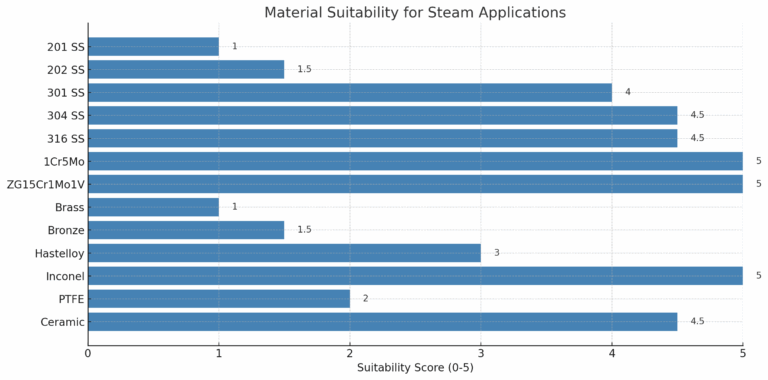

| 301 | High strength, good corrosion and heat resistance | Valve springs, stems | Steam lines, high-pressure valve parts |

| 304 | Excellent all-around performance | Valve bodies, covers, seats | Chemical, food, pharmaceutical valves |

| 316 | Superior corrosion resistance, especially to chlorides | Valve internals in harsh environments | Marine, paper, desalination, acid-handling systems |

4.2 Extended Materials for Valves

Alloy Steels:

1Cr5Mo / 1Cr9Mo: Suitable for 400–700°C, high strength and oxidation resistance.

ZG15Cr1Mo1V: Used in high-pressure, high-temperature steam systems.

Copper Alloys:

Brass (H62, H68): Good for low-pressure water and anti-static applications.

Bronze (QSn4-3): Resistant to ammonia, ideal for marine valves.

Nickel-Based Alloys:

Hastelloy C-276, B-2: Extreme resistance to strong acids (HCl, H2SO4).

Inconel 625: Excellent for high temperature and chloride exposure.

Non-Metallic Materials:

PTFE (Teflon): Chemically inert, ideal for pharmaceutical and high-purity systems.

Ceramics (Alumina, Silicon Nitride): Best for abrasive or erosive services.

5. Conclusion

The correct material selection for control valves depends on operating temperature, pressure, corrosion level, and media composition. Stainless steels such as 304 and 316 offer high performance for most general and corrosive services, while specialized alloys or non-metals are used for extreme conditions. Material selection should always align with long-term safety, maintenance cost, and system reliability goals.