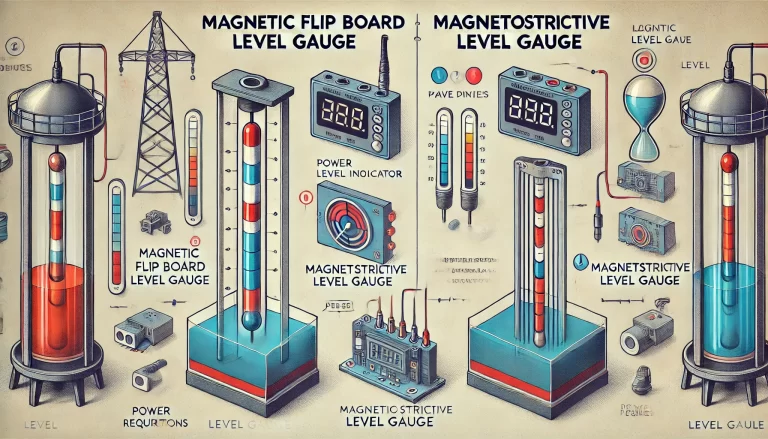

Accurately measuring liquid levels is crucial in various industries such as oil and gas, chemical processing, and power generation. Two commonly used devices for liquid level measurement are Magnetic Flip Board Level Gauges (also known as Magnetic Float Level Gauges) and Magnetostrictive Level Gauges. This article provides a comprehensive comparison of these two technologies across several key aspects, including working principles, measurement accuracy, functional features, applicable scenarios, and installation/maintenance considerations.

1. Working Principle

Magnetic Flip Board Level Gauge:

The Magnetic Flip Board Level Gauge operates based on the principles of buoyancy and magnetic coupling. When the liquid level inside a container rises or falls, a magnetic float inside the gauge body tube moves accordingly. The float contains a permanent magnet that interacts with an external visual indicator consisting of red and white flipping columns. As the float moves, it causes the columns to flip 180°, indicating the actual liquid level based on the interface between red and white colors.

Key Characteristics:

Visual display based on magnetic coupling

Direct observation without power requirements

Suitable for high-temperature and high-pressure applications

Magnetostrictive Level Gauge:

The Magnetostrictive Level Gauge works on the principle of pulse transmission and magnetic field interaction. An electronic circuit generates an initial pulse, which travels through a waveguide wire inside the probe. When the pulse interacts with the magnetic field from the float, it generates a torsional strain via the magnetostrictive effect. This strain is converted into an electrical signal by a pickup sensor, and the time difference between pulses is used to precisely calculate the liquid level.

Key Characteristics:

High precision with real-time electronic measurement

Requires power supply

Capable of multi-level measurement

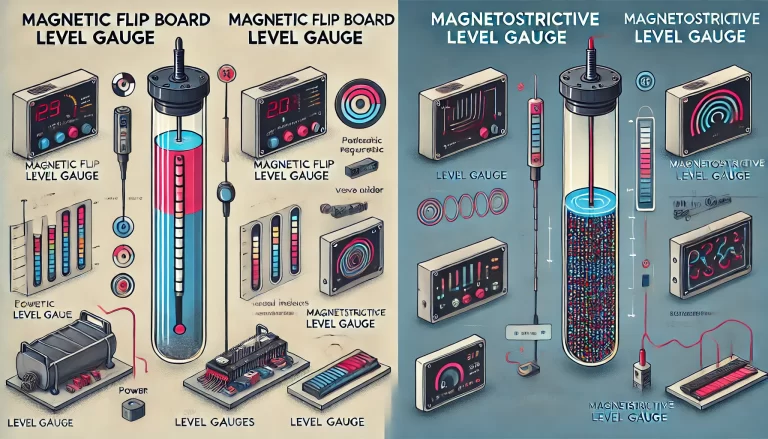

2. Measurement Accuracy

Magnetic Flip Board Level Gauge:

Measurement accuracy is relatively low compared to electronic methods.

Typically suitable for applications where high precision is not required.

Accuracy: approximately ±10mm.

Magnetostrictive Level Gauge:

Provides high precision and resolution, making it suitable for demanding applications.

Offers a resolution of up to 0.1mm, ensuring reliable and consistent measurements.

Less affected by environmental factors such as pressure and temperature changes.

3. Functional Features

Magnetic Flip Board Level Gauge:

Advantages:

Provides direct, on-site visual observation.

Simple design with no need for electrical power.

Can include optional reed switch transmitters for remote monitoring.

Resistant to clogging and leakage, ideal for harsh environments.

Limitations:

Limited to single-level measurement.

No digital data storage capabilities.

Manual observation required.

Magnetostrictive Level Gauge:

Advantages:

High-precision continuous level measurement.

Digital display via LCD screens for easy remote access.

Can store data and integrate into automation systems.

Suitable for detecting multiple liquid layers.

Limitations:

Higher cost compared to flip board gauges.

Requires periodic calibration and maintenance.

4. Application Scenarios

Magnetic Flip Board Level Gauge:

Widely used in:

Petroleum, chemical, and power industries.

Suitable for measuring liquid levels in large storage tanks, pressure vessels, and boilers.

Ideal for outdoor installations due to robust design and visibility.

Magnetostrictive Level Gauge:

Preferred for:

High-precision applications such as chemical storage and oil inventory management.

Tank farms where real-time monitoring is required.

Suitable for detecting multiple fluid interfaces in stratified liquids.

5. Installation and Maintenance

Magnetic Flip Board Level Gauge:

Should be installed vertically to ensure accurate readings.

Placement should avoid areas near inlet/outlet pipes to prevent measurement disturbances.

Regular maintenance includes cleaning the main tube to prevent buildup.

Magnetostrictive Level Gauge:

Typically installed through existing tank nozzles on the top or side.

Requires minimal maintenance compared to mechanical gauges.

Calibration may be required periodically to ensure accuracy.

Conclusion

Both the Magnetic Flip Board Level Gauge and the Magnetostrictive Level Gauge have their own unique advantages and are suited for different applications. The choice between the two depends on factors such as required accuracy, budget, ease of maintenance, and environmental conditions.

Choose Magnetic Flip Board Level Gauge if you need a cost-effective, visual, and durable solution for large industrial tanks with moderate accuracy requirements.

Choose Magnetostrictive Level Gauge if high precision, data logging, and remote monitoring are essential for your operations.

Understanding the differences and selecting the right device based on operational needs can optimize efficiency and cost-effectiveness in liquid level monitoring systems.