1. Introduction

Solenoid valves are widely used actuators in industrial process control. Their performance and safety characteristics are closely related to the type of power supply. The two most common options are 24V DC (direct current) and 220V AC (alternating current) solenoid valves. This article provides a systematic comparison between the two, covering power supply, safety, electrical characteristics, noise, reliability, and application suitability, followed by practical selection guidelines.

2. Power Supply and Safety

24V DC Solenoid Valve

Requires a dedicated DC power supply.

Operates at low voltage, reducing the risk of electric shock and providing higher safety compliance.

220V AC Solenoid Valve

Can be connected directly to standard industrial AC mains without additional conversion.

Operates at high voltage, which increases the risk of safety incidents if protective measures are inadequate.

3. Electrical Characteristics

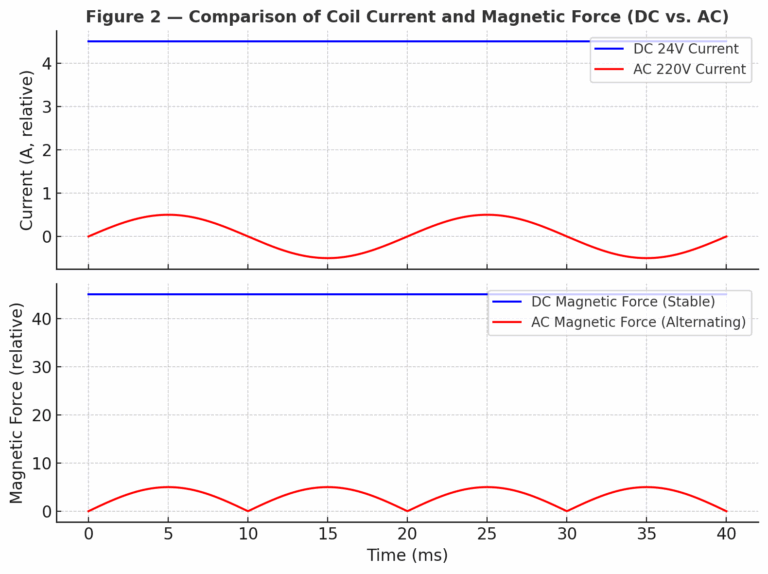

Current Consumption

For the same rated power, a 24V DC coil requires approximately nine times more current than a 220V AC coil.

AC coils draw smaller current, making them more suitable for long-distance wiring.

Magnetic Force Profile

DC: Initial pull force is relatively weak but becomes stronger and more stable after engagement.

AC: Magnetic force fluctuates with the alternating current waveform, resulting in less stability and noticeable vibration.

4. Structure and Reliability

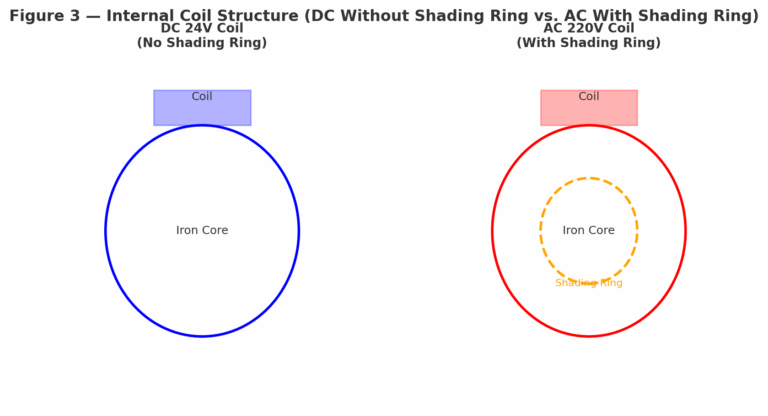

Coil Design

AC solenoids include a short-circuit (shading) ring to reduce electromagnetic vibration.

DC solenoids do not require a shading ring.

Failure Modes

AC: Coil noise and overheating may occur if the valve mechanism sticks, stroke mismatch exists, or if the shading ring becomes loose or damaged. Such issues can quickly lead to coil burnout.

DC: Coil heating may still occur under blockage, but the risk is generally lower compared to AC types.

5. Noise and Heating

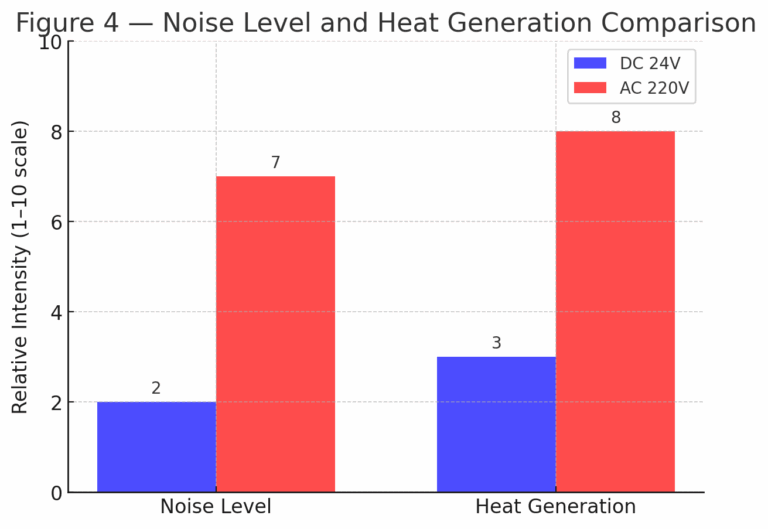

Noise

AC solenoids tend to generate a humming sound during operation due to alternating force.

DC solenoids operate much more quietly.

Heating

Both AC and DC coils heat up during extended energization.

AC solenoids are more prone to rapid overheating and failure; continuous energization should be avoided.

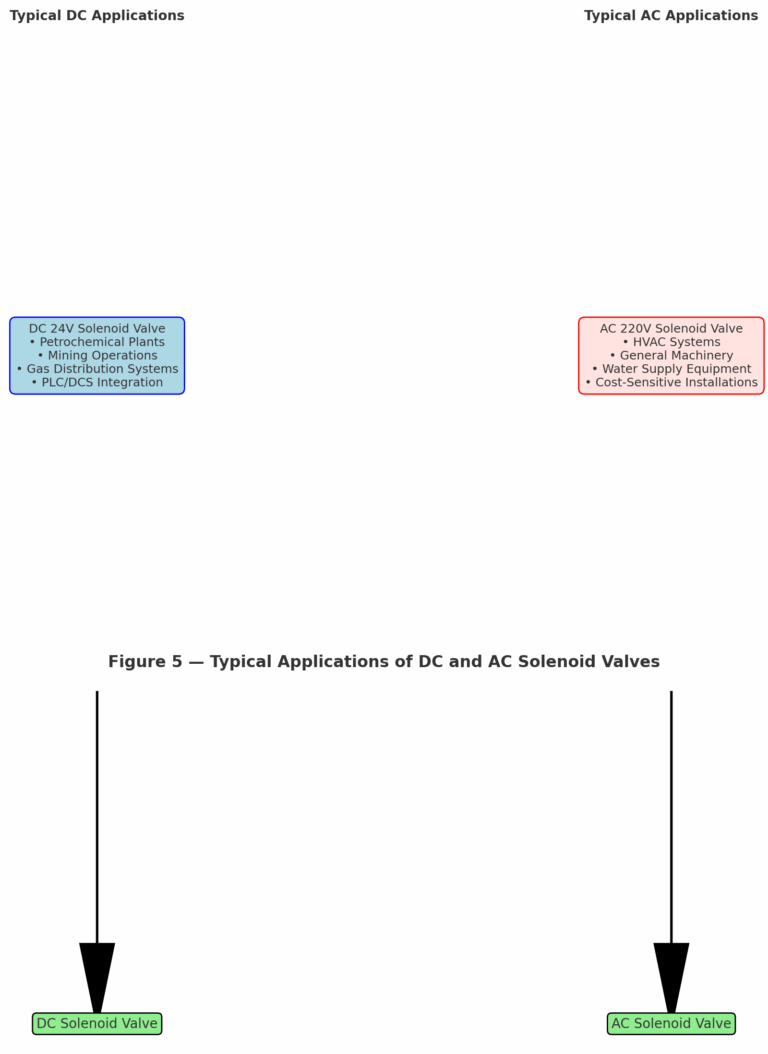

6. Application Scenarios

24V DC Solenoid Valve

Preferred in environments requiring high safety standards, such as petrochemical plants, mining sites, and gas distribution systems.

Compatible with PLC, DCS, and other low-voltage control systems.

220V AC Solenoid Valve

Suitable for general-purpose industrial applications where AC power is readily available.

Commonly used in HVAC systems, general machinery, and low-cost installations.

7. Selection Guidelines

Prioritize 24V DC solenoid valves when safety is the primary concern.

Use 220V AC solenoid valves when DC power supply capacity is insufficient or unavailable, ensuring that additional safety measures (e.g., insulation sleeves, protective enclosures) are implemented.

Electrical design recommendations:

Route AC and DC wiring separately to minimize interference and risks.

Reinforce protection for AC220V circuits.

For long service life, select solenoids with surge suppression and low operating current.

8. Conclusion

Safety: 24V DC offers higher intrinsic safety.

Electrical Characteristics: DC consumes higher current but delivers stable magnetic force; AC consumes lower current but exhibits alternating force.

Reliability: AC solenoids are vulnerable to shading ring failures; DC solenoids are comparatively more stable.

Noise: DC solenoids are significantly quieter.

Application Fit: Choose 24V DC where safety and low-voltage integration are critical; use 220V AC where power availability and cost efficiency dominate.

👉 Engineering best practice: Avoid continuous energization of solenoids to prevent excessive heating and premature coil failure.