Flow measurement is a critical process in various industries such as oil and gas, chemicals, and manufacturing. Among the many types of flowmeters available, turbine flowmeters and vortex flowmeters are widely used due to their reliability and precision. This article compares these two types of flowmeters, focusing on their design principles, application fields, structural characteristics, and measurement accuracy.

Design Principles

Turbine Flowmeters:

Turbine flowmeters operate based on the rotation of a turbine placed within the flow path of a fluid. When fluid passes through the meter, it strikes the turbine blades, generating a torque that causes the turbine to spin. The rotational speed of the turbine is proportional to the velocity of the fluid.

By detecting the rotational speed, typically through magnetic or optical sensors, the flow rate can be accurately calculated. In essence, turbine flowmeters harness the kinetic energy of the fluid to drive the turbine, translating this motion into a flow measurement.

Vortex Flowmeters:

Vortex flowmeters are designed based on the Kármán vortex street principle. When fluid flows past a bluff body, such as a triangular prism, alternating vortices are generated downstream of the bluff body. The frequency of these vortices is directly proportional to the flow velocity.

Sensors placed in the flowmeter detect these vortices, converting the frequency into a flow rate. This method is highly effective for measuring various types of fluids, as the vortex frequency is largely unaffected by changes in fluid properties.

Application Fields

Turbine Flowmeters:

Turbine flowmeters find extensive application in measuring the flow of clean, low-viscosity fluids. Typical applications include:

Petroleum products (e.g., gasoline, diesel, and kerosene)

Organic and inorganic liquids

Liquefied gases and natural gas

Cryogenic fluids

These meters are valued for their simplicity, lightweight design, and ability to handle high-pressure and high-temperature conditions. However, they require regular maintenance in applications where fluid properties, such as viscosity, can vary significantly.

Vortex Flowmeters:

Vortex flowmeters are versatile instruments used to measure the flow of liquids, gases, and steam. Common applications include:

Industrial process control for gas and steam flow

Measurement of fluids in chemical and petrochemical industries

Utility management in power plants

The key advantages of vortex flowmeters are their minimal pressure loss, wide range of measurable flow rates, and high accuracy. They are particularly effective in environments where fluid density, viscosity, pressure, or temperature might fluctuate.

Structural Characteristics

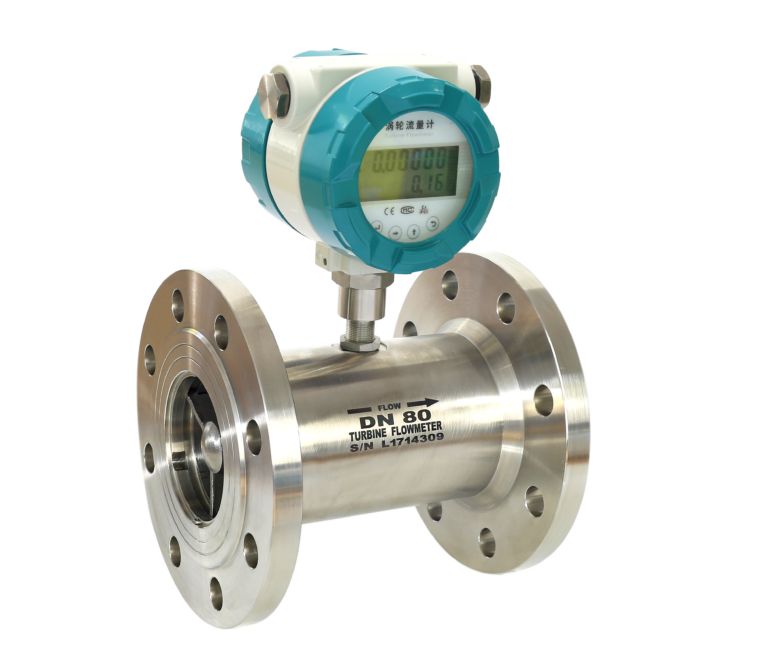

Turbine Flowmeters:

Turbine flowmeters typically consist of the following components:

Turbine Rotor: Positioned within the flow path and supported by bearings.

Guide Mechanism: Ensures stable fluid flow.

Housing: Protects the internal components from external damage.

Signal Transmitter: Converts turbine rotations into readable flow data.

The design is relatively simple, but precision-engineered components, such as the turbine blades and bearings, ensure accurate measurements. Maintenance is critical to prevent wear and tear, especially in high-pressure or abrasive environments.

Vortex Flowmeters:

Vortex flowmeters include:

Bluff Body: Generates alternating vortices.

Sensor System: Detects vortex frequency.

Flow Transmitter: Converts sensor data into flow measurements.

Their robust construction allows for reliable operation across a wide range of applications. The bluff body and sensor placement are optimized to reduce errors and ensure consistent performance.

Measurement Accuracy

Turbine Flowmeters:

Turbine flowmeters are highly precise, with typical accuracy ranging between ±0.5% and ±1%. However, their performance can be influenced by fluid properties such as viscosity, temperature, and pressure. Careful calibration is necessary to maintain accuracy.

Vortex Flowmeters:

Vortex flowmeters generally have a slightly lower accuracy than turbine flowmeters, with an error range of ±1% to ±2%. However, they are less sensitive to changes in fluid properties and can handle fluids with impurities, such as dust, particles, or bubbles, making them ideal for broader industrial applications.

Choosing the Right Flowmeter

When deciding between a turbine flowmeter and a vortex flowmeter, consider the following factors:

Fluid Type: Use turbine flowmeters for clean, low-viscosity fluids and vortex flowmeters for mixed or impure fluids.

Operating Conditions: Turbine flowmeters excel under stable conditions, while vortex flowmeters are better suited for fluctuating environments.

Accuracy Requirements: Both meters are accurate, but turbine flowmeters might be preferable when ultra-high precision is required.

Maintenance Needs: Vortex flowmeters generally require less maintenance, making them more suitable for challenging industrial applications.

Conclusion

Both turbine and vortex flowmeters are indispensable tools in modern fluid measurement. While turbine flowmeters offer high precision and are well-suited for clean fluids, vortex flowmeters provide versatility and reliability in more varied conditions. Understanding their design principles, applications, and limitations is essential for selecting the most appropriate meter for specific operational needs. By considering the unique characteristics of each, industries can achieve accurate and efficient flow measurement tailored to their requirements.