Abstract

Orifice plates and nozzles are two of the most widely used primary elements in differential pressure (DP) flow measurement. Both create a localized constriction in the pipeline to generate a pressure drop, which is then related to flow rate using Bernoulli’s and continuity equations. Despite sharing the same principle, they differ significantly in geometry, hydrodynamic performance, accuracy, durability, cost, and application suitability. This paper provides a six-dimension comparative analysis to support engineering selection and design decisions.

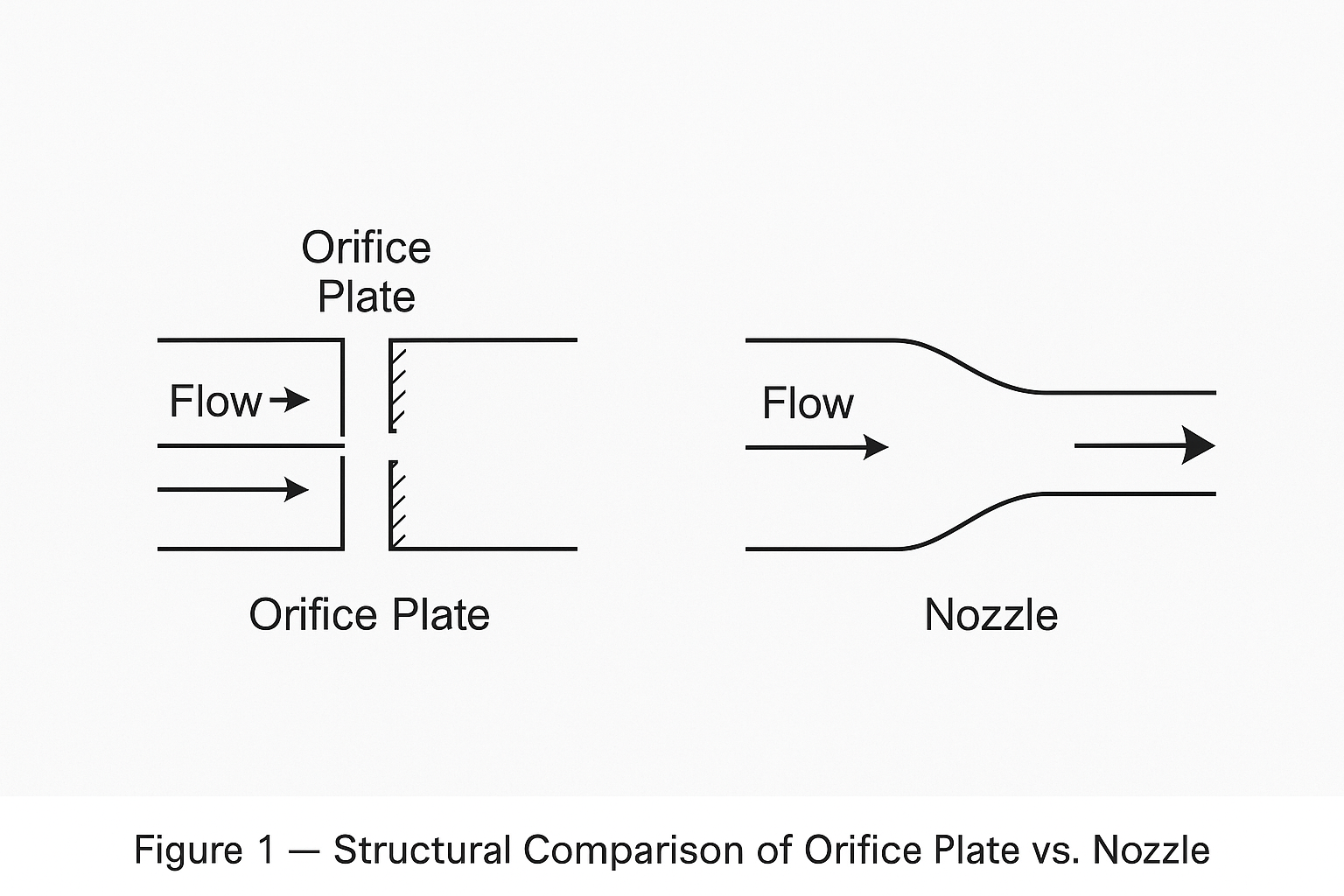

1. Structural and Geometric Characteristics

Orifice Plate

Simplest structure: a thin metal plate with a sharp-edged circular hole at the center.

Small thickness, with the sharp edge being the most critical feature.

Flow contracts suddenly, forming a clear vena contracta downstream.

Nozzle

More complex, streamlined construction.

Smooth rounded inlet (elliptical or quarter-circle) converging to a cylindrical throat.

Throat length ≈ 0.3–0.5 × diameter.

Flow contracts progressively and reaches minimum cross-section in the throat.

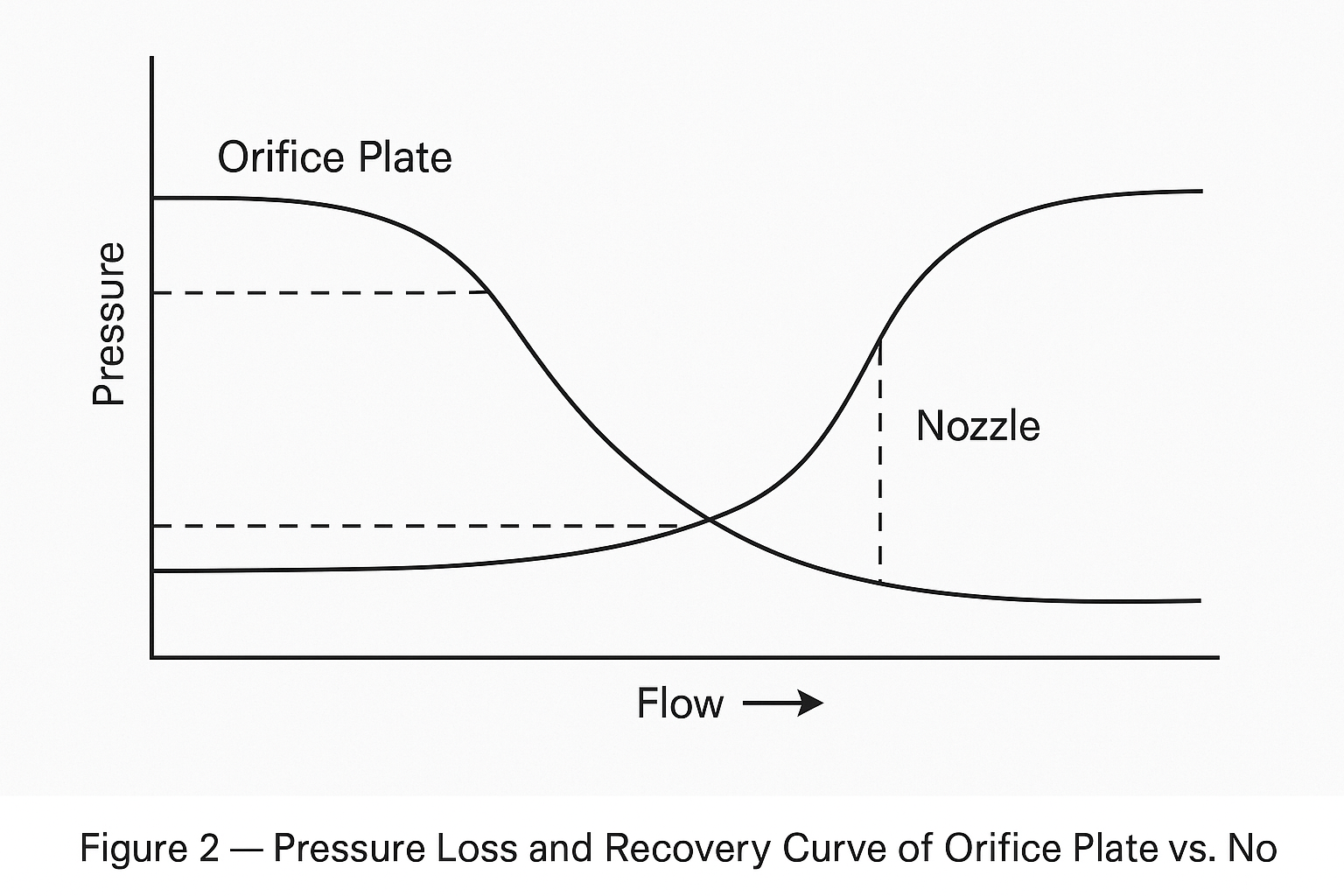

2. Hydrodynamic Characteristics and Pressure Loss

Orifice Plate

Sudden contraction and expansion generate strong vortices and turbulence.

High permanent pressure loss: ~40–80% of differential pressure is lost.

Low pressure recovery.

Nozzle

Streamlined profile guides fluid smoothly, reducing turbulence.

Lower permanent pressure loss: only ~10–20% of differential pressure is lost.

Better pressure recovery.

3. Accuracy and Rangeability

Orifice Plate

Accuracy highly dependent on sharp edge condition.

Sensitive to upstream flow disturbance; requires longer straight runs.

Typical rangeability: 3:1 to 4:1.

Accuracy deteriorates at low Reynolds numbers.

Nozzle

Flow coefficient more stable, less affected by wear or fouling.

Less sensitive to upstream disturbance; shorter straight runs are acceptable.

Higher accuracy, especially in medium flow ranges.

Rangeability up to 4:1 to 5:1, maintaining accuracy at lower Reynolds numbers.

Table 1 — Comparative Accuracy and Rangeability of Orifice Plate vs. Nozzle

| Parameter | Orifice Plate | Nozzle |

|---|---|---|

| Accuracy | Strongly dependent on sharp edge condition; easily affected by wear, fouling, and edge rounding | More stable due to streamlined profile; less sensitive to wear and fouling |

| Sensitivity to Upstream Disturbance | High; requires longer upstream straight runs (≥10–20D typical) | Lower; can operate with shorter upstream straight runs (≈5–10D typical) |

| Performance at Low Reynolds Number | Accuracy deteriorates rapidly; limited stability | Maintains better accuracy and stability at low Reynolds numbers |

| Rangeability (Max/Min Flow Ratio) | 3:1 to 4:1 | 4:1 to 5:1 |

| Repeatability | Moderate; influenced by installation and edge condition | High; stable flow coefficient with good repeatability |

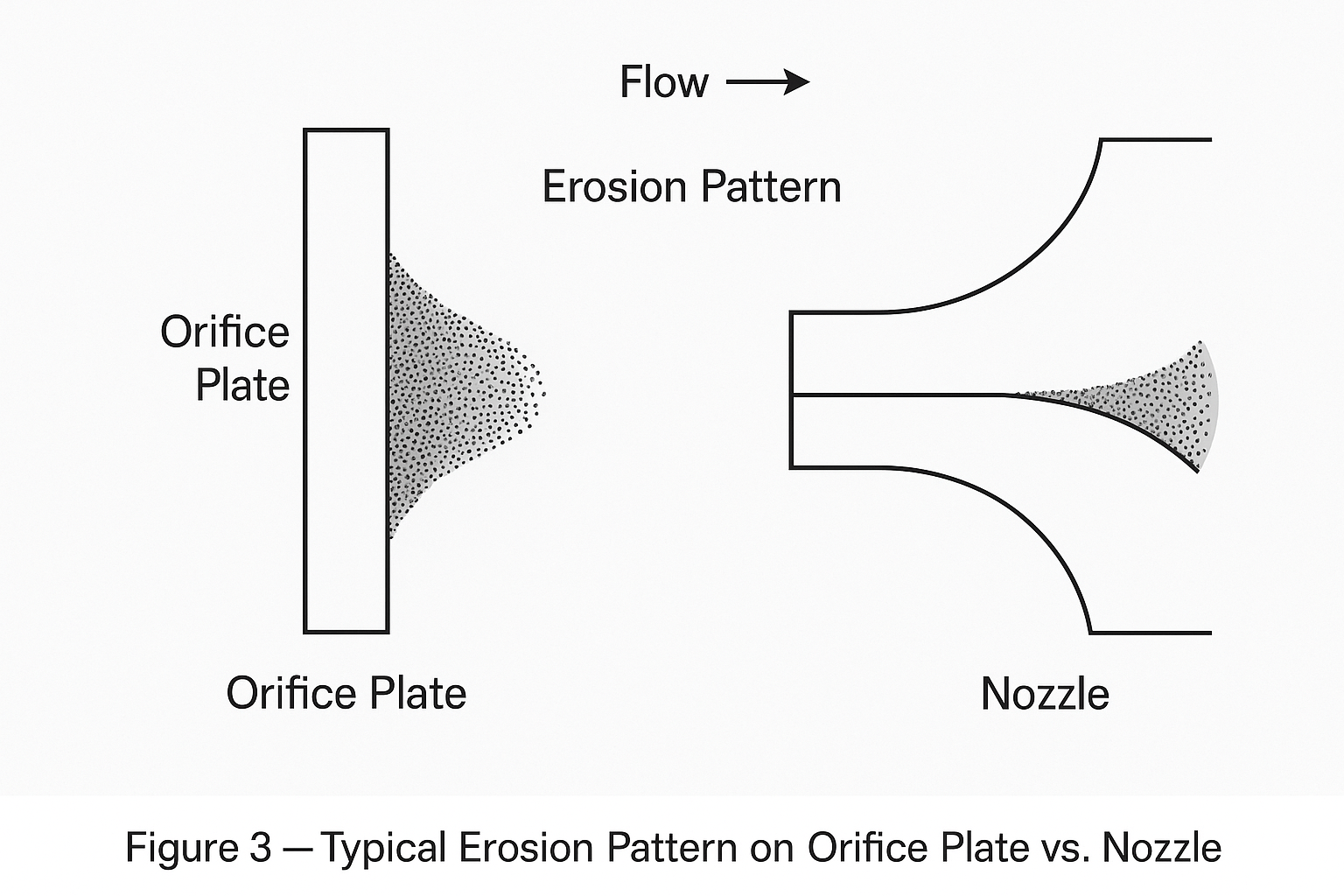

4. Wear and Corrosion Resistance

Orifice Plate

Sharp edge prone to erosion and corrosion, especially with solids or corrosive fluids.

Frequent inspection and replacement required.

Deposits easily form on edges.

Nozzle

Smooth curved inlet more resistant to erosion and fouling.

Self-cleaning effect in many cases.

Generally longer service life.

5. Cost Considerations

Orifice Plate: Lowest cost, easy to manufacture.

Nozzle: More complex and costly due to precision machining requirements.

Table 2 — Cost and Maintenance Frequency Comparison

| Parameter | Orifice Plate | Nozzle |

|---|---|---|

| Initial Manufacturing Cost | Very low — simple thin plate with sharp-edged bore | Significantly higher — requires precision machining of curved inlet and throat |

| Installation Cost | Low; easy to install and replace | Higher; requires careful alignment and higher machining tolerances |

| Maintenance Frequency | High — sharp edge wears quickly; frequent inspection and replacement needed | Low — streamlined profile resists erosion and fouling; less frequent replacement |

| Service Life | Shorter; typically months to a few years depending on fluid conditions | Longer; often several years even under harsh operating conditions |

| Lifecycle Cost | Low initial cost but high long-term maintenance cost | Higher initial cost but reduced maintenance yields lower lifecycle cost |

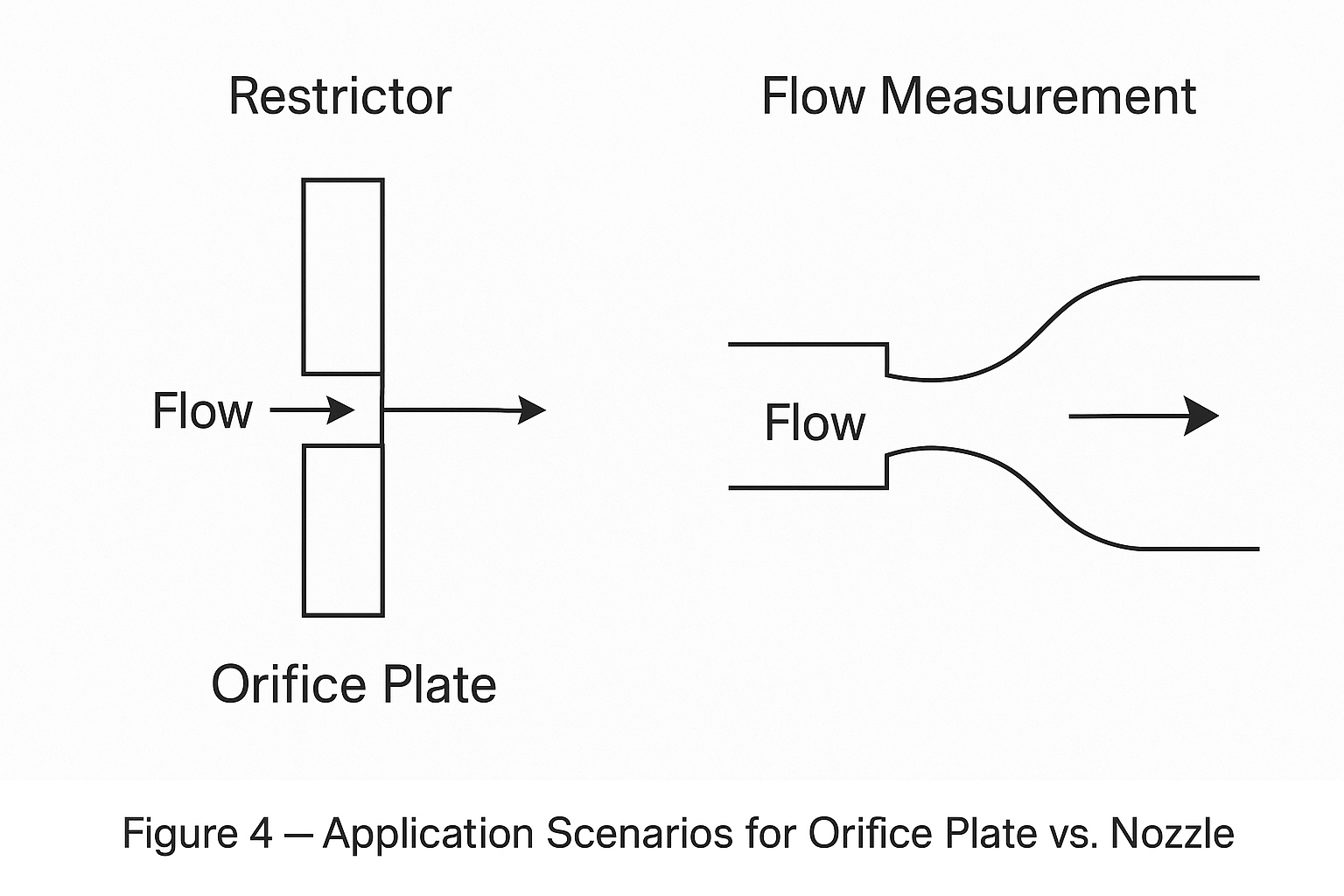

6. Typical Application Scenarios

Orifice Plate

Cost-sensitive projects.

Clean fluids (liquids or gases).

Large pipelines where cost advantage is significant.

Applications where permanent pressure loss is not critical.

Widely standardized (ISO 5167, ASME MFC-3M).

Nozzle

Applications requiring higher accuracy and repeatability.

Energy-sensitive systems requiring lower permanent pressure loss (e.g., steam flow).

High-temperature, high-pressure, or high-velocity fluids.

Fluids containing small amounts of solids or prone to fouling.

Installations with limited upstream straight run.

7. Summary Comparison Table

| Dimension | Orifice Plate | Nozzle |

|---|---|---|

| Structure | Thin plate, sharp edge | Streamlined curved inlet, throat |

| Pressure Loss | High (40–80%) | Low (10–20%) |

| Accuracy | Edge-condition dependent, lower stability | Higher stability and repeatability |

| Rangeability | 3:1–4:1 | 4:1–5:1 |

| Durability | Prone to erosion and fouling | Resistant, self-cleaning |

| Cost | Low | Higher |

| Applications | Cost-driven, clean fluids, large pipe sizes | Steam, high-pressure/high-velocity fluids, energy-sensitive, fouling fluids |

Table 3 — Six-Aspect Comparison of Orifice Plate vs. Nozzle

| Dimension | Orifice Plate | Nozzle |

|---|---|---|

| Structure & Geometry | Thin flat plate with sharp-edged bore; sudden contraction; simple design | Streamlined curved inlet and cylindrical throat; gradual contraction; more complex design |

| Hydrodynamic Characteristics & Pressure Loss | High turbulence and vortices; permanent pressure loss ~40–80%; poor pressure recovery | Smooth flow guidance; permanent pressure loss ~10–20%; better pressure recovery |

| Accuracy & Rangeability | Accuracy highly dependent on sharp edge; sensitive to flow profile; rangeability 3:1–4:1 | Higher accuracy and repeatability; less sensitive to flow disturbances; rangeability 4:1–5:1 |

| Wear & Corrosion Resistance | Edge prone to erosion, corrosion, and fouling; frequent inspection/replacement required | More resistant to wear and fouling; self-cleaning effect; longer service life |

| Cost | Lowest cost; easy to manufacture and replace | Higher cost due to precision machining and complex design |

| Typical Applications | Cost-sensitive projects, clean fluids, large-diameter pipelines, non-critical energy loss conditions | High-accuracy steam/energy-sensitive flows, high T/P fluids, fouling or particulate-laden fluids, limited straight-run installations |

Conclusion

Orifice plates are cost-effective, simple, and widely standardized, but they suffer from higher energy losses, greater wear sensitivity, and limited rangeability. Nozzles, though more expensive, provide higher accuracy, lower permanent pressure loss, better durability, and are suitable for demanding operating conditions.

The selection between these two devices should be based on fluid properties, process conditions, required accuracy, available installation space, and budget constraints.