In thermal control systems, proper wiring plays a crucial role in ensuring the stability of signal transmission and the safe operation of equipment. However, due to improper design, poor maintenance, or incorrect installation practices, common wiring issues often arise. These problems can lead to signal interference, equipment malfunctions, and even safety hazards. Below are some of the most frequent wiring issues encountered in thermal control systems, along with recommended solutions to mitigate their impact.

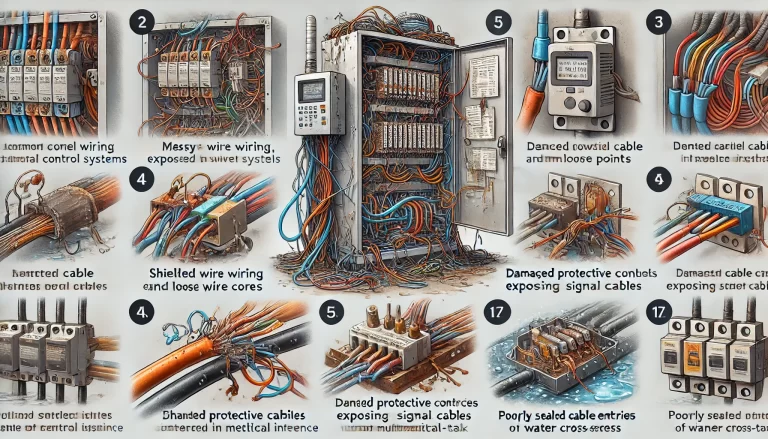

1. Improper Wiring Inside Control Cabinets

One common issue is that the exposed length of wire cores inside control cabinets is too long. This can lead to:

Increased risk of short circuits between wires.

Loose connections, which can cause unreliable signal transmission.

Solution:

Ensure that the exposed wire length is minimized and properly insulated.

Use ferrules or terminal lugs to secure the wire connections and prevent loosening over time.

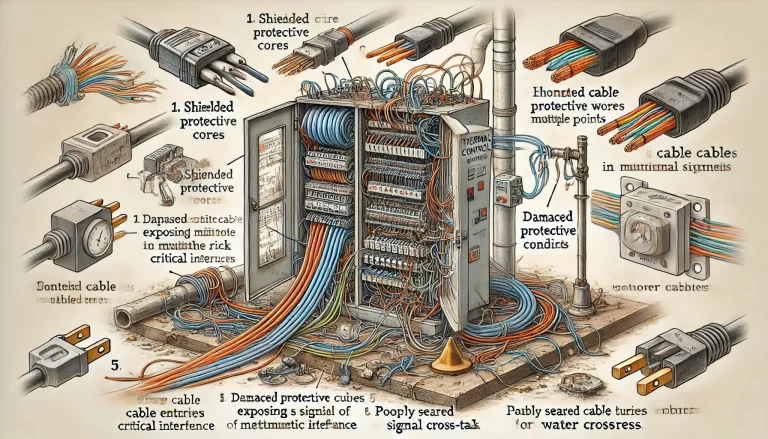

2. Multiple Grounding Points for Shielded Cables

Shielded cables are used to protect signals from electromagnetic interference. However, if a shielded cable is grounded at multiple points, it can create ground loops, leading to:

Increased noise interference in signals.

Unstable readings and erroneous data in control systems.

Solution:

Always use a single-point grounding method to minimize interference.

Ensure that the shield is only grounded at the designated location, typically at the control panel or grounding bar.

3. Damage or Loss of Protective Conduit for Signal Cables

In field installations, signal cables are usually enclosed in protective conduits to prevent physical damage. When these conduits are damaged or missing, cables are exposed to:

Mechanical wear and tear, increasing the likelihood of breakage.

Moisture ingress, which can lead to short circuits and signal degradation.

Solution:

Regularly inspect protective conduits and replace any damaged sections.

Use high-quality, weather-resistant conduit materials to ensure long-term durability.

4. Corrosion and Rusting of Junction Boxes and Control Cabinets

Environmental factors such as humidity, chemicals, and extreme temperatures can lead to rust and corrosion in electrical enclosures, resulting in:

Poor electrical conductivity due to corroded terminals.

Increased risk of short circuits and equipment failures.

Solution:

Use stainless steel or corrosion-resistant enclosures for outdoor and harsh environments.

Apply protective coatings or anti-rust treatments to prevent deterioration.

Ensure proper sealing of cabinets and junction boxes to limit moisture ingress.

5. Improper Separation of Signal and Power Cables

Signal cables and power cables should be routed separately to prevent electromagnetic interference (EMI). However, in many installations, they are placed too close together, leading to:

Signal distortions due to EMI from power cables.

Unstable temperature sensor readings in thermal control systems.

Solution:

Maintain a sufficient separation distance between power and signal cables.

Use shielded signal cables and properly grounded metal conduits to minimize interference.

6. Overloading Multiple Critical Signals in a Single Cable

When multiple important signals share a single cable, it increases the risk of:

Signal cross-talk and interference, reducing signal accuracy.

A single point of failure that can affect multiple critical functions.

Solution:

Distribute important signals across multiple cables to prevent interference.

Use individually shielded twisted pairs for sensitive signals to minimize cross-talk.

7. Inadequate Cable Entry Protection Leading to Water Ingress

Poor cable entry methods in junction boxes or cabinets can allow water and moisture to enter, resulting in:

Short circuits and equipment damage.

Corrosion of internal wiring and terminals.

Solution:

Use proper cable glands and sealing materials to prevent water ingress.

Ensure all entry points are weatherproof and properly installed.

Conclusion

Addressing these common wiring issues in thermal control systems is essential for maintaining signal integrity, equipment reliability, and operational safety. By following best practices in wiring, grounding, shielding, and environmental protection, organizations can minimize potential risks and ensure long-term system stability. Regular inspections and proactive maintenance are also key to preventing these issues before they escalate into serious problems.