Introduction

Relays are essential components in modern industrial automation and power systems. They act as switching and protection devices, enabling safe and efficient control of electrical circuits. Depending on the application—whether for signal amplification, overload protection, safety shutdown, or high-frequency switching—different types of relays are used. This article provides a structured overview of the most common industrial relays and their applications.

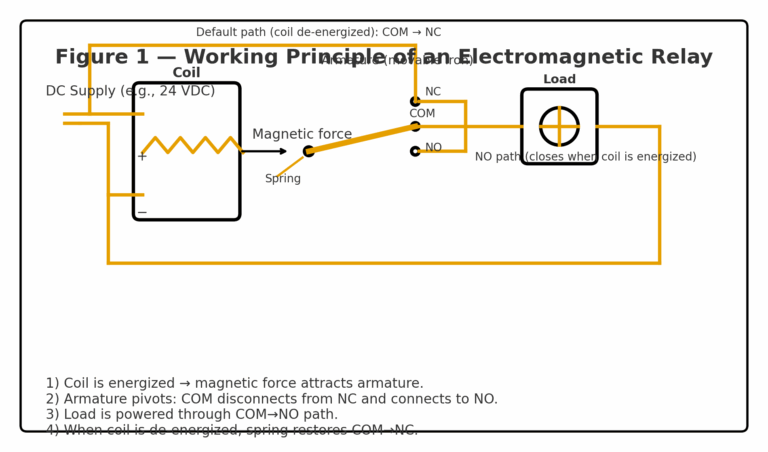

1. Electromagnetic Relay (EMR)

Principle: Operates through the magnetic attraction of an energized coil, which opens or closes mechanical contacts.

Applications:

General-purpose switching

Control circuits in PLC/DCS systems

Motor control and small-load switching

Advantages: Simple, low cost, reliable.

Limitations: Mechanical wear and slower response compared to solid-state relays.

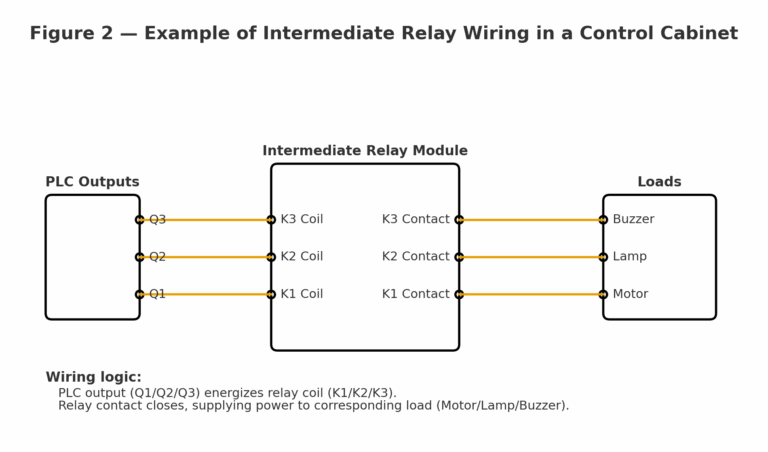

2. Intermediate Relay

Role: Serves as an interface between control systems and field devices.

Applications:

Signal isolation and amplification

Expanding the number of contacts in control logic

Advantages: Compact design, suitable for multi-point control.

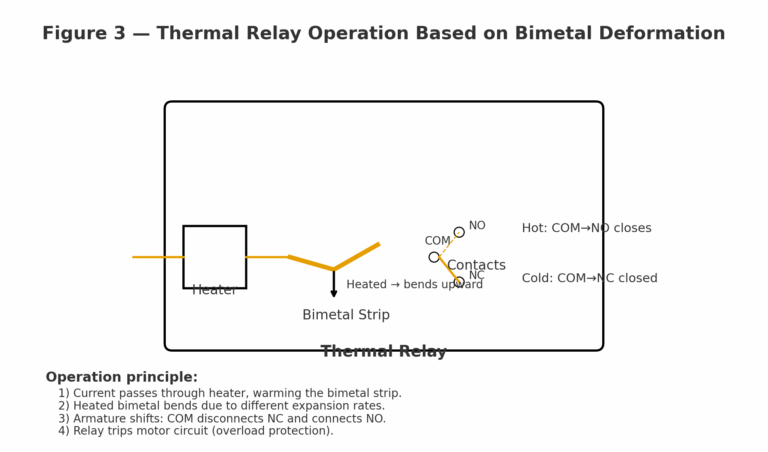

3. Thermal Overload Relay

Principle: Uses a bimetal strip that bends under heat to trigger an overload trip.

Applications:

Protecting induction motors against overload

Low-voltage motor starter panels

Advantages: Cost-effective and reliable overload protection.

Limitations: Not suitable for short-circuit protection.

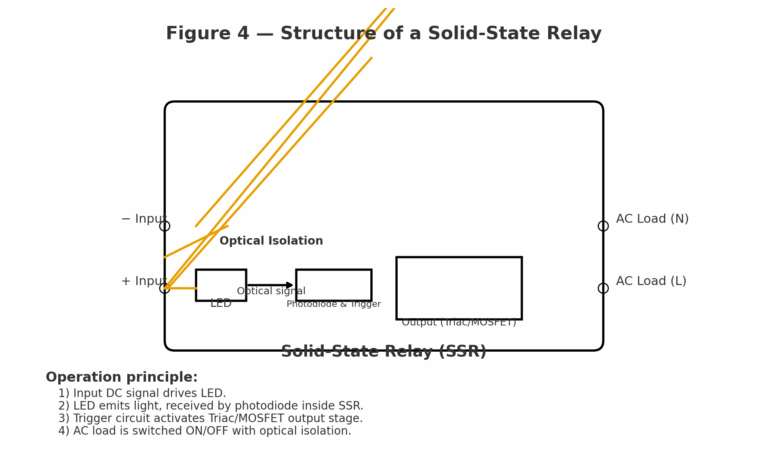

4. Solid-State Relay (SSR)

Principle: Utilizes semiconductor components (e.g., thyristors, MOSFETs) for switching.

Applications:

High-frequency switching

Heating element control

Silent switching in clean environments

Advantages: Long service life, fast response, no mechanical wear.

Limitations: Heat dissipation required, higher cost.

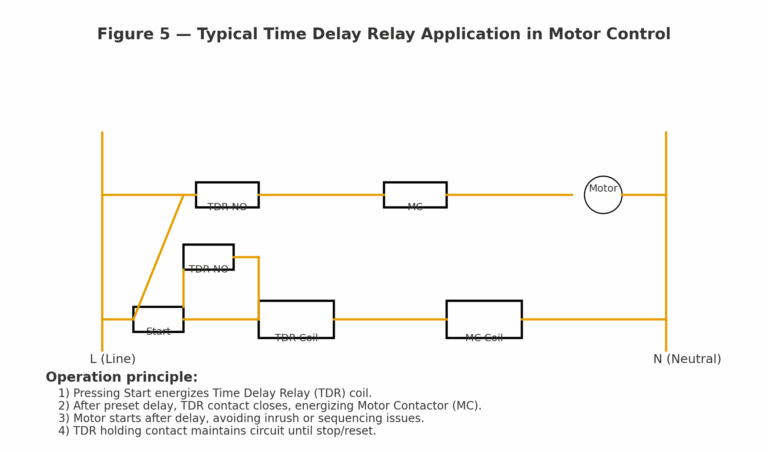

5. Time Delay Relay

Function: Provides a preset time delay for switching operations.

Applications:

Sequential motor start-up

Delay in alarm and control circuits

Types: On-delay and off-delay timers.

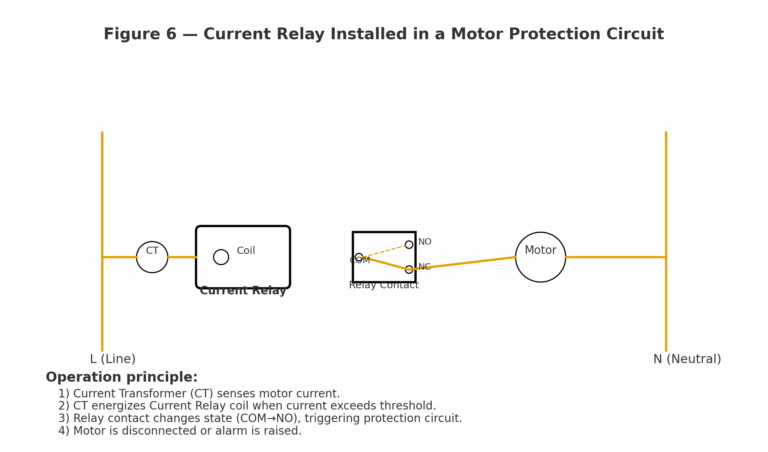

6. Voltage and Current Relays

Function: Monitor voltage or current values and trigger switching when limits are exceeded.

Applications:

Overvoltage and undervoltage protection

Overcurrent monitoring

Typical Usage: In substations, power distribution systems, and industrial panels.

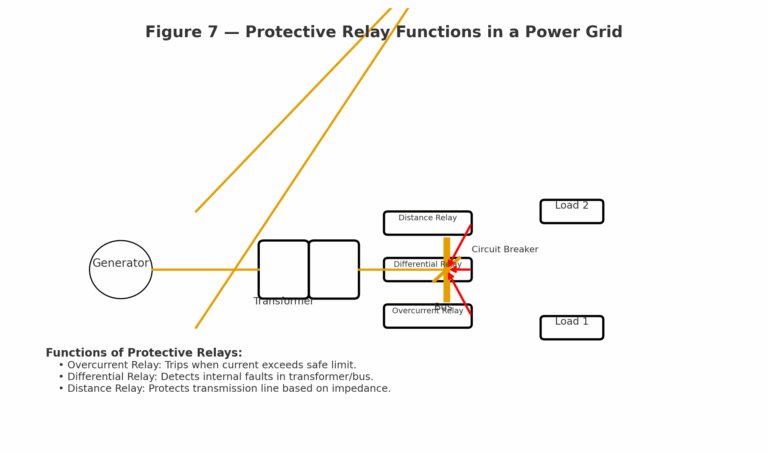

7. Protective Relays

Types: Overcurrent relay, differential relay, earth-fault relay, distance relay.

Applications:

Power transmission and distribution protection

Transformer and generator protection

Advantages: Ensures system stability and safety during abnormal conditions.

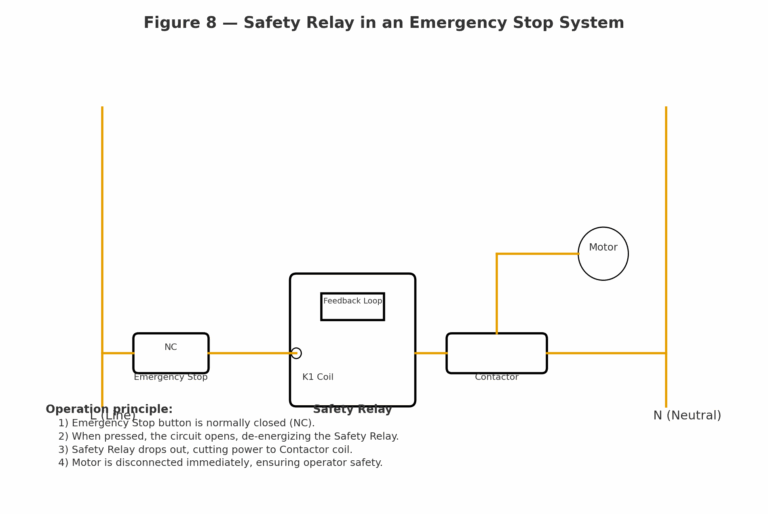

8. Safety Relays

Purpose: Ensure compliance with safety standards such as IEC 61508 or ISO 13849.

Applications:

Emergency stop (E-stop) circuits

Safety door monitoring

Two-hand control systems

Advantages: High reliability, mandatory in safety-critical applications.

Comparison Table

| Relay Type | Key Feature | Main Application | Advantages | Limitations |

|---|---|---|---|---|

| Electromagnetic Relay | Coil + contacts | General switching | Low cost, simple | Mechanical wear |

| Intermediate Relay | Signal isolation | PLC/DCS interface | Compact, versatile | Limited load capacity |

| Thermal Relay | Bimetal strip | Motor overload protection | Simple, cost-effective | No short-circuit protection |

| Solid-State Relay (SSR) | Semiconductor switching | High-frequency switching | Long life, fast response | Heat dissipation needed |

| Time Delay Relay | Adjustable delay | Sequential control | Flexible timing | Limited to timing function |

| Voltage/Current Relay | Electrical monitoring | Voltage/current protection | Accurate protection | Narrow application scope |

| Protective Relay | System fault detection | Power grid safety | Comprehensive protection | Complex, costly |

| Safety Relay | Safety compliance | Emergency & safety circuits | High reliability | Higher cost |

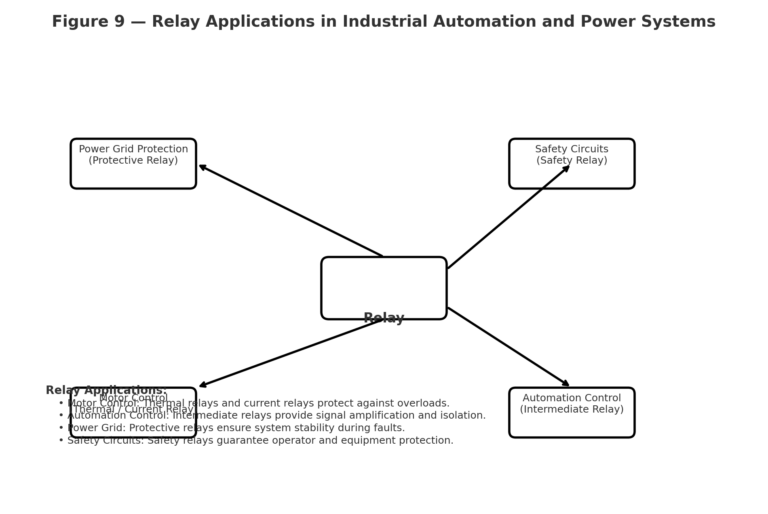

Industrial Applications

Automation Systems: Intermediate relays for signal amplification.

Motor Control: Thermal relays to prevent overload damage.

Heating Control: Solid-state relays in furnaces and dryers.

Power Systems: Protective relays for grid stability.

Safety Circuits: Safety relays for emergency stop buttons.

Conclusion

Relays remain a cornerstone of industrial automation and electrical protection. From classic electromagnetic relays to modern solid-state and safety relays, each type serves a specific role in ensuring operational reliability, safety, and efficiency. Understanding the functions and proper application of relays helps engineers and maintenance teams design robust and safe control systems.