Electrical interfaces in instruments often involve threaded connections for signal cables, pressure sensors, or other components. These threads vary based on regional standards, industry requirements, and specific applications. Below is a detailed overview of the common thread standards used in electrical interfaces for instruments.

1. International Standard Threads

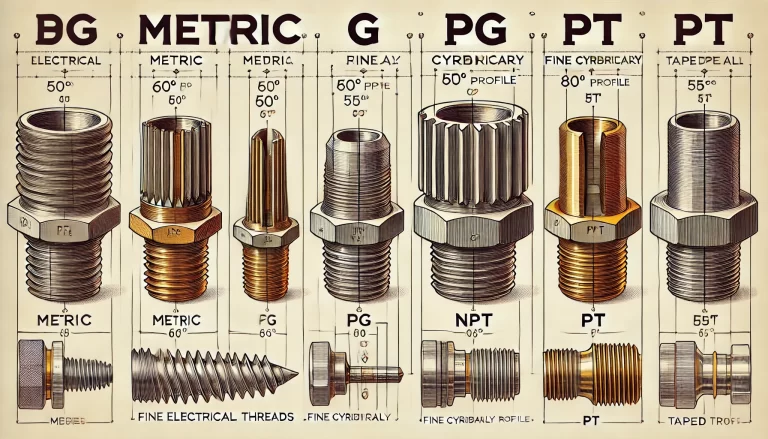

NPT (National Pipe Thread)

- Overview:

NPT threads are the U.S. standard for tapered pipe threads, widely used in North America. They are characterized by their conical shape, which provides a tight seal through thread deformation. - Applications:

Commonly used in high-pressure environments such as gas pipelines, hydraulic systems, and industrial sensors. - Sizes:

Standard sizes include NPT 1/8, NPT 1/4, NPT 1/2, and NPT 3/4. - Seal Mechanism:

Requires thread sealant, such as PTFE tape or pipe dope, to ensure leak-proof connections.

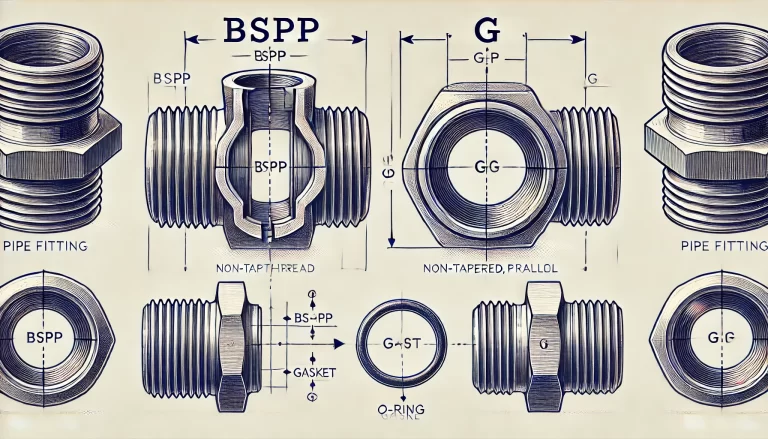

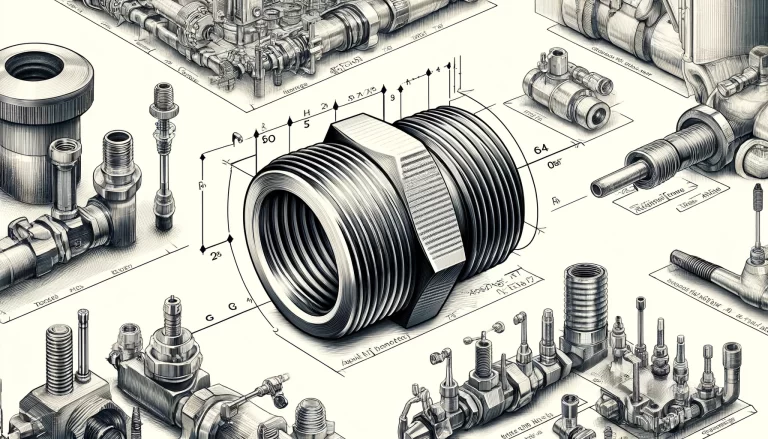

BSP (British Standard Pipe Thread)

- Overview:

BSP threads are the standard in the UK and many other regions globally. They are divided into:- BSPT (British Standard Pipe Tapered): Tapered threads for sealing.

- BSPP (British Standard Pipe Parallel): Straight threads that require additional sealing elements.

- Applications:

Found in industrial, pneumatic, and hydraulic systems, as well as many European-designed instruments. - Sizes:

Common sizes include BSP 1/4, BSP 1/2, and BSP 3/4. BSPP threads are often marked with a “G” (e.g., G1/2).

ISO 228

- Overview:

ISO 228 is an international standard similar to BSPP. It defines straight threads intended for use with sealing washers or O-rings. - Applications:

Used in general-purpose instrumentation, especially in Europe and globally standardized devices. - Seal Mechanism:

Relies on a sealing element like an O-ring.

2. Metric Threads

ISO Metric Threads (ISO 261)

- Overview:

Metric threads are the international standard for general-purpose fasteners and are commonly used in many industries, including instrumentation. - Applications:

Found in electrical connectors, sensors, and mounting interfaces in globally distributed devices. - Sizes:

Metric thread sizes are indicated with an “M” followed by the nominal diameter and pitch, e.g., M16×1.5, M20×1.5. - Seal Mechanism:

Typically uses gaskets, sealing rings, or other supplementary components.

3. Region-Specific Standards

DIN Threads

- Overview:

DIN standards are widely used in Germany and neighboring European countries. They specify detailed thread requirements for hydraulic and pneumatic systems. - Examples:

- DIN 3852: Defines thread dimensions for fluid power systems.

- DIN EN 60423: Covers thread dimensions for electrical conduit systems.

JIS Threads

- Overview:

JIS (Japanese Industrial Standard) threads are predominantly used in Japan. These include PT threads, which are equivalent to BSPT. - Applications:

PT threads are commonly seen in instrumentation designed for Asian markets.

ANSI/ASME Threads

- Overview:

These American standards define Unified Fine (UNF) and Unified Coarse (UNC) threads, used for mechanical fasteners and specific instrumentation mounts.

4. Specialized Threads

PG Threads (Panzergewinde)

- Overview:

PG threads are a German standard for electrical cable glands and connectors. They are particularly suited for securing cables in enclosures. - Applications:

Widely used in electrical panel wiring and junction boxes. - Sizes:

PG threads are numbered (e.g., PG9, PG11, PG13.5).

UNF/UNC Threads

- Overview:

Unified threads with fine or coarse pitches are commonly used in instruments where mechanical precision is critical. - Applications:

Found in pressure gauges, sensor housings, and some connector fittings.

5. Key Considerations for Thread Selection

Pressure Requirements:

For high-pressure applications, tapered threads like NPT and BSPT are preferred due to their self-sealing properties.Sealing Mechanisms:

Straight threads (e.g., BSPP, ISO 228) typically require sealing components like O-rings or gaskets, while tapered threads rely on thread deformation and sealants.Regional Compatibility:

Select threads based on the geographical location and target market to ensure standard compliance and compatibility with existing equipment.Application Type:

Use thread standards suited to the specific environment (e.g., industrial, hydraulic, or electrical).

Summary

The choice of thread standard for electrical interfaces in instruments depends on factors such as regional standards, application requirements, and sealing needs. Understanding the differences between common thread types (e.g., NPT, BSP, ISO Metric, DIN, and PG) ensures proper installation, reliable operation, and leak-free performance. Always refer to the equipment’s specification sheets to ensure compatibility with the selected thread standard.