Introduction

Ultrasonic level meters are widely used in liquid and solid level measurements due to their non-contact and wear-free advantages. However, many users face inaccurate readings during actual applications, leading to accumulated errors in production processes or even equipment failures, which can compromise the stability of an entire production line. This article will analyze the common reasons behind inaccurate measurements in ultrasonic level meters, such as blind spots and environmental interference, and provide corresponding solutions based on practical experiences.

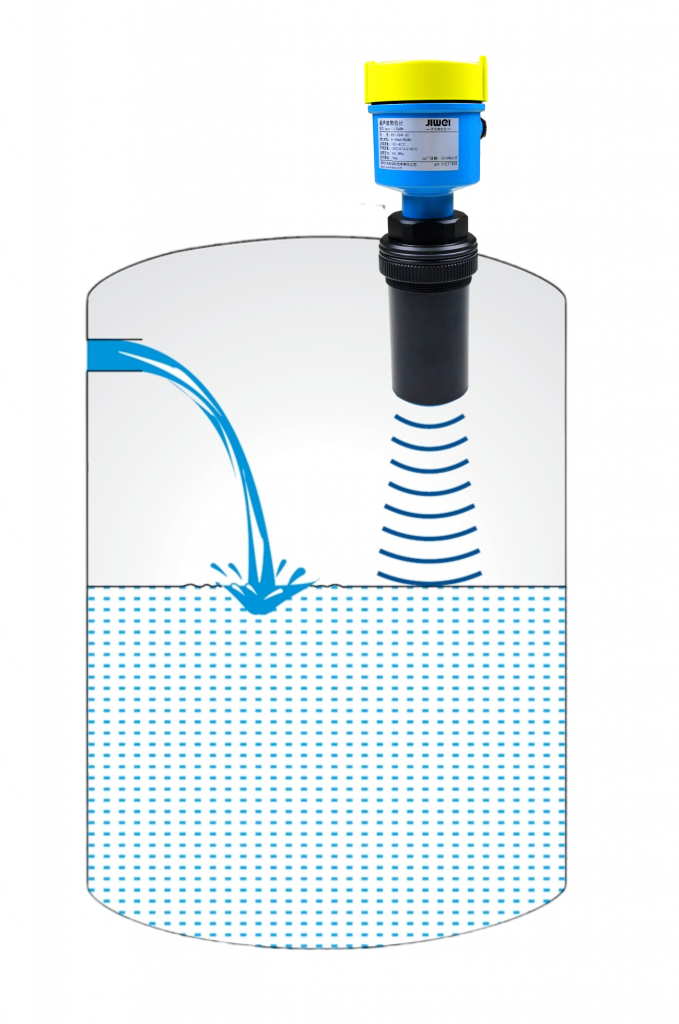

1. Principle of Measurement and Common Issues Overview

An ultrasonic level meter works by emitting an ultrasonic signal and receiving the reflected signal to calculate the level. Although the principle seems simple, many factors in different environments can affect its accuracy. Common issues include inaccurate measurements, drift, blind spots, environmental noise interference, and more. Understanding the root causes of these issues is crucial to improving measurement accuracy.

2. Common Problems Affecting Measurement Accuracy

2.1 Drift Due to Temperature Variations

Temperature is a significant factor influencing the accuracy of ultrasonic level meters. The speed of sound varies with temperature, and in environments with large temperature differences, this can lead to measurement errors.

Solutions:

- Choose an ultrasonic level meter with temperature compensation: Some models come with built-in temperature compensation to account for temperature fluctuations.

- Regular maintenance: Ensure that the temperature compensation function is working effectively by periodically checking the device.

- Use alternative technologies in extreme conditions: In environments with extreme temperature variations, consider using radar-based level meters, which are less affected by temperature changes.

Example: In a large tank where the temperature fluctuates drastically, installing an ultrasonic level meter without temperature compensation might cause readings to vary by several centimeters throughout the day. Using a compensated model can minimize such discrepancies.

2.2 Interference from Steam, Bubbles, and Foam

If there are a significant amount of bubbles, foam, or steam on the liquid surface, the ultrasonic signal can be severely affected. These factors can cause incomplete or erroneous signal reflections, leading to inaccurate measurements.

Solutions:

- Install a protective cover or reflector above the sensor: This can help reduce the interference from bubbles and steam.

- Choose installation locations with minimal exposure to steam or bubbles: Avoid placing the sensor directly in areas where there is high steam or bubble concentration.

- Use radar level meters: Radar signals are not affected by steam and can provide more stable readings in such environments.

Example: In an industrial setting where high temperatures produce steam, installing an ultrasonic level meter without considering the presence of steam could lead to significant errors in liquid level readings. Installing the meter above the steam or opting for a radar level meter can ensure more accurate data.

2.3 Blind Spot Issues

Ultrasonic level meters have a minimum measurable distance, known as the blind spot. If the liquid surface falls below this distance, the sensor cannot correctly reflect the signal, causing it to fail to detect the level.

Solutions:

- Choose the appropriate sensor with the correct minimum measurement range: Selecting a model that suits the specific application and liquid surface height is essential.

- Use meters with adjustable range settings: Some models allow for adjustable measurement ranges to accommodate various liquid levels.

- Install multiple sensors: In cases where the liquid surface may fall below the minimum range, installing multiple meters at different heights can provide accurate readings.

Example: In a tank with a very low liquid level, if only one ultrasonic sensor is installed with a high minimum measuring distance, it may fail to detect the level accurately. Installing a second sensor at a lower position or choosing one with a smaller blind spot can solve this issue.

2.4 Improper Installation

The installation angle, location, and environmental conditions of the ultrasonic level meter play a crucial role in the measurement accuracy. Incorrect installation can cause signal instability and affect the measurement precision.

Solutions:

- Follow the manufacturer’s installation guidelines: Ensure that the device is installed vertically and in accordance with the product specifications.

- Avoid installation in areas with strong airflow, temperature differences, or obstacles: These factors can disrupt the signal.

- Regular inspection: Periodically check the device’s installation to ensure no vibrations or external factors have caused it to shift.

Example: If an ultrasonic level meter is installed at a slight angle, the signal may not reflect correctly, leading to errors. Ensuring the sensor is installed per specifications and regularly checked will prevent such problems.

2.5 Impact of Meteorological Conditions

Ultrasonic level meters are also influenced by weather conditions, particularly in outdoor or areas where atmospheric pressure changes significantly. Fluctuations in atmospheric pressure can alter the speed of sound, which in turn affects measurement accuracy.

Solutions:

- Select an appropriate level meter: For environments with fluctuating atmospheric pressure, consider using a model designed to compensate for pressure changes.

- Use heaters and anti-freeze protection: In extreme weather conditions, ensure that the device is equipped with heating elements or freeze protection to maintain stable operation.

Example: In outdoor applications where the atmospheric pressure changes rapidly, such as during weather fronts or seasonal shifts, using a non-compensated ultrasonic level meter may result in inconsistent readings. Choosing a pressure-compensated device or adding supplementary systems can help mitigate this.

2.6 Electromagnetic Interference and Noise

Electromagnetic interference from industrial equipment or mechanical noise can disrupt the ultrasonic signals, causing drifts or instability in the measurements.

Solutions:

- Use ultrasonic level meters with electromagnetic interference protection: Some models are designed to resist interference and enhance signal processing.

- Install the sensor away from noise sources: Position the level meter away from electrical equipment, transformers, or other sources of electromagnetic noise.

- Opt for specialized models in noisy environments: In high-noise industrial environments, using models specifically designed to filter out electromagnetic interference ensures stable operation.

Example: In a factory with high electromagnetic noise, installing an ultrasonic level meter without proper shielding may lead to erratic readings. A model with advanced electromagnetic interference protection would be essential for stable performance.

3. Troubleshooting and Solutions

3.1 Regular Calibration and Maintenance

To maintain the accuracy of ultrasonic level meters, they should be regularly calibrated and maintained, especially in environments with significant liquid level fluctuations or frequent environmental changes. Routine checks of the sensor for dust or impurities are essential to ensure smooth signal transmission.

3.2 Choosing the Right Model and Installation Plan

Selecting the correct model based on the specific application scenario is vital. For example, in high-temperature, high-pressure, or corrosive environments, specialized models should be chosen. Additionally, attention should be paid to the installation height, angle, and orientation to ensure the signal is unobstructed.

3.3 Data Analysis and Diagnostics

Utilizing data monitoring systems to track the real-time status of ultrasonic level meters allows for quick identification of problems. By comparing real-time level data with historical data, abnormal fluctuations can be detected early and addressed promptly.

4. Conclusion

There are numerous reasons for inaccurate measurements in ultrasonic level meters, ranging from temperature variations to interference from bubbles, installation errors, and more. By selecting the appropriate equipment, performing regular calibration, and optimizing the installation environment, measurement accuracy can be greatly improved. For complex applications, alternative technologies, such as radar level meters, can be considered as supplementary or replacement solutions to ensure stable and accurate measurements.

If your ultrasonic level meter is not providing accurate readings, start troubleshooting by looking into environmental factors, installation issues, and device selection. Regular maintenance and calibration will significantly enhance the performance and precision of your equipment.