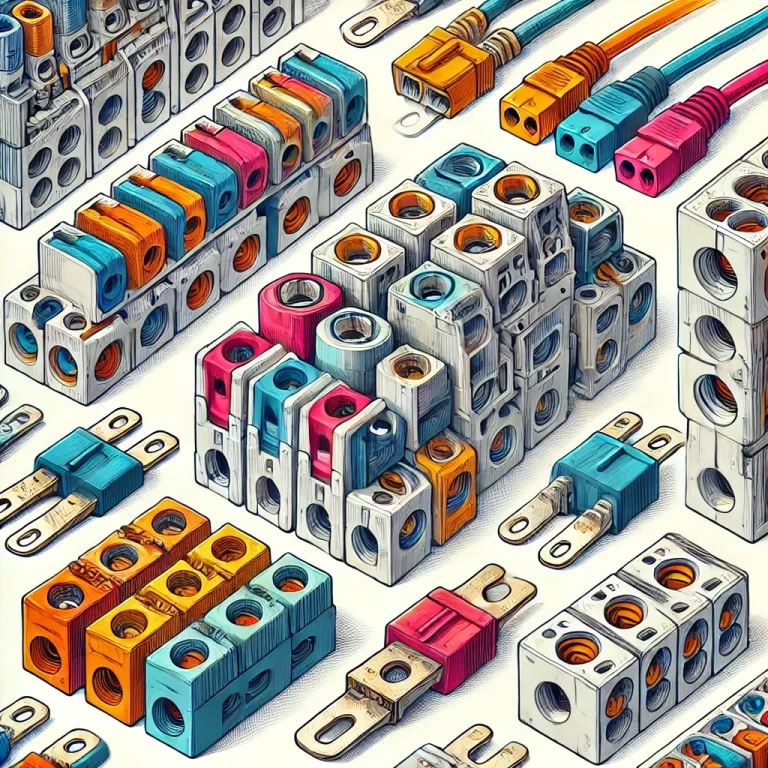

The plastic insulation material and conductive components of terminal blocks are directly related to their quality, as they determine the terminal’s insulation and conductivity performance, respectively.

Common faults of terminal blocks include:

Loose Connections: Over time, connections may become loose due to vibrations, thermal cycling, or improper tightening during installation, leading to poor electrical contact.

Corrosion: Exposure to moisture, chemicals, or other harsh environments can cause corrosion on the conductive parts, which can degrade the electrical connection and increase resistance.

Overheating: Excessive current or poor connections can cause overheating, which may lead to the melting of insulation or even damage to the conductive components.

Insulation Failure: The insulation material can degrade over time, especially under extreme temperatures or exposure to UV light, leading to potential short circuits or electrical leakage.

Cracking or Breaking of Plastic Housing: The plastic housing of the terminal block can become brittle and crack over time, particularly if it is exposed to harsh environmental conditions or mechanical stress.

Incorrect Wire Insertion: Wires may be incorrectly inserted or not fully seated in the terminal, leading to poor electrical contact and potential disconnection.

Cross-Talk: Poor design or installation can lead to electrical noise or cross-talk between adjacent terminals, affecting the signal integrity.

Mechanical Wear and Tear: Frequent connection and disconnection can cause mechanical wear on the terminals, leading to poor contact or failure over time.

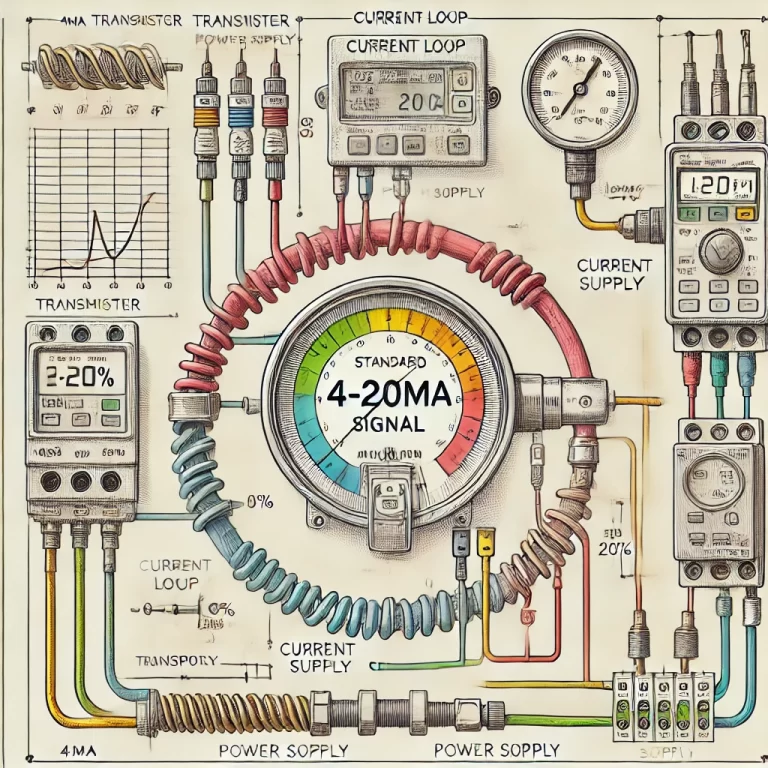

The standard signal of 4-20mA is widely used in industrial automation and control systems for several important reasons:

Live-Zero Signal (4mA as the Minimum): The signal starts at 4mA rather than 0mA, which allows for the detection of issues like a broken wire or malfunctioning sensor. If the current falls below 4mA, it indicates a fault, making troubleshooting easier.

Noise Immunity: The 4-20mA signal is less susceptible to electrical noise and interference compared to voltage signals. Current signals maintain their integrity over long distances, even in electrically noisy environments.

Signal Linearity: The 4-20mA signal provides a linear relationship between the signal and the process variable it represents, which simplifies interpretation and processing in control systems.

Powering Field Instruments: Some field instruments can be loop-powered by the same 4-20mA signal, eliminating the need for a separate power supply and reducing wiring complexity.

Standardization: The 4-20mA signal is a well-established industry standard, ensuring compatibility between devices from different manufacturers and simplifying system integration.

Wide Range: The 4-20mA range allows for a good balance between resolution and the ability to detect small changes in the process variable.

These reasons make the 4-20mA current loop a reliable and effective choice for transmitting analog signals in industrial applications.

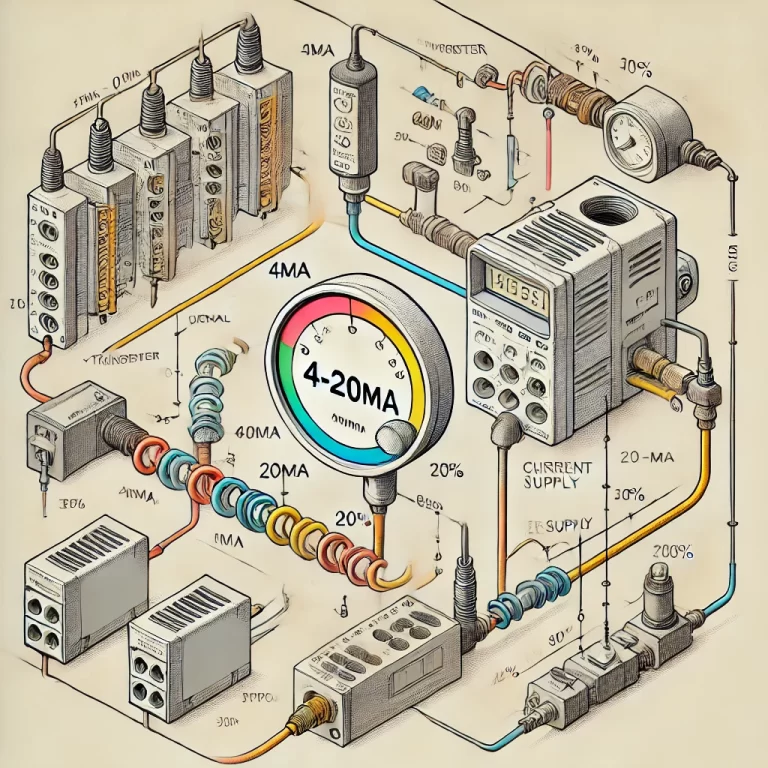

The advantages of using a 4-20mA current signal include:

Long Distance Transmission: Current signals, unlike voltage signals, are not significantly affected by the resistance of the wiring. This allows the 4-20mA signal to be transmitted over long distances without loss of signal strength.

Immunity to Electrical Noise: Current loops are highly resistant to electrical noise and electromagnetic interference, making them ideal for industrial environments where such noise is common.

Simple Fault Detection: Since the signal range starts at 4mA instead of 0mA, any signal lower than 4mA can easily indicate a fault, such as a broken wire or a malfunctioning sensor. This is often referred to as “live zero” detection.

Linear Signal: The 4-20mA signal provides a linear relationship between the signal and the measurement, making it easy to interpret the signal and convert it into a meaningful measurement.

Loop Power Capability: Many field instruments can be powered directly by the current loop itself, eliminating the need for a separate power source and simplifying the wiring.

Standardization and Compatibility: The 4-20mA signal is an industry-standard, ensuring that devices from different manufacturers can communicate with each other without compatibility issues.

Wide Range: The 4-20mA range provides sufficient resolution for accurate measurement and control, making it suitable for various industrial applications.

Safety: Since the maximum current is only 20mA, it poses minimal risk of sparking in hazardous environments, making it a safe choice for use in areas with flammable gases or dust.