1. Introduction

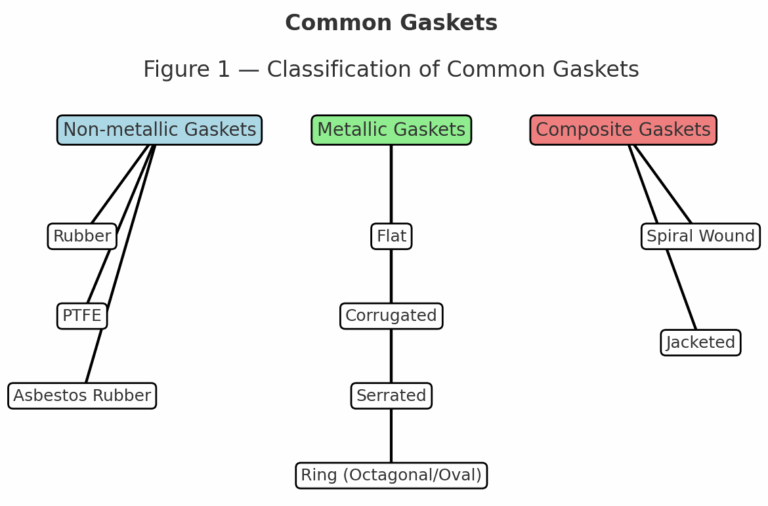

Gaskets are essential sealing elements widely applied in chemical plants, pipelines, and pressure vessels. Their performance directly affects the tightness, safety, and reliability of the system. According to the material and construction, gaskets can be divided into non-metallic gaskets, metallic gaskets, and metal composite gaskets.

2. Non-Metallic Gaskets

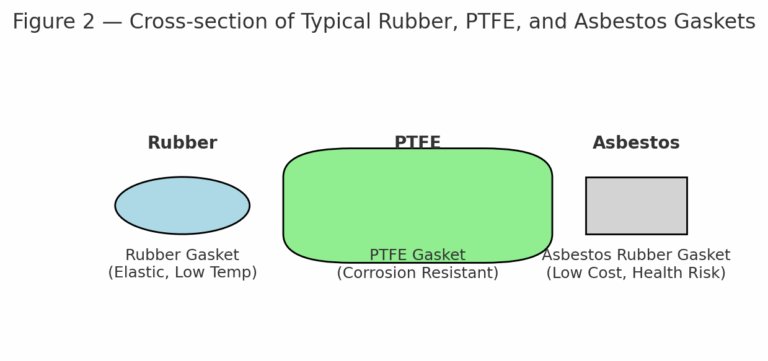

2.1 Rubber Gaskets

Natural Rubber (NR): Excellent elasticity, suitable for water, seawater, and air. Can maintain stable performance above –60 °C.

Nitrile Rubber (NBR): Good oil resistance, suitable for petroleum products. Performs well at low temperature.

Neoprene Rubber (CR): Resistant to seawater, weak acids, and weak alkalis; good chemical stability.

Fluororubber (FKM): Outstanding resistance to strong acids, strong alkalis, and oxidizing media. Not recommended for solvents such as benzene, ketones, and ethers.

2.2 PTFE Gaskets

Excellent chemical resistance against strong acids, alkalis, and halogens.

Widely used in chemical processes requiring high corrosion resistance.

Limitation: prone to cold flow and creep under high temperature and high pressure.

Safe operating temperature: ≤150 °C; pressure: ≤1 MPa.

2.3 Asbestos Rubber Gaskets

Made of asbestos fibers and rubber. Low cost and easy to use.

Suitable for water, steam, and inert gases at low to medium temperature and pressure.

Note: Asbestos is carcinogenic and banned in many regions. Alternative non-asbestos fiber gaskets are recommended.

3. Metallic Gaskets

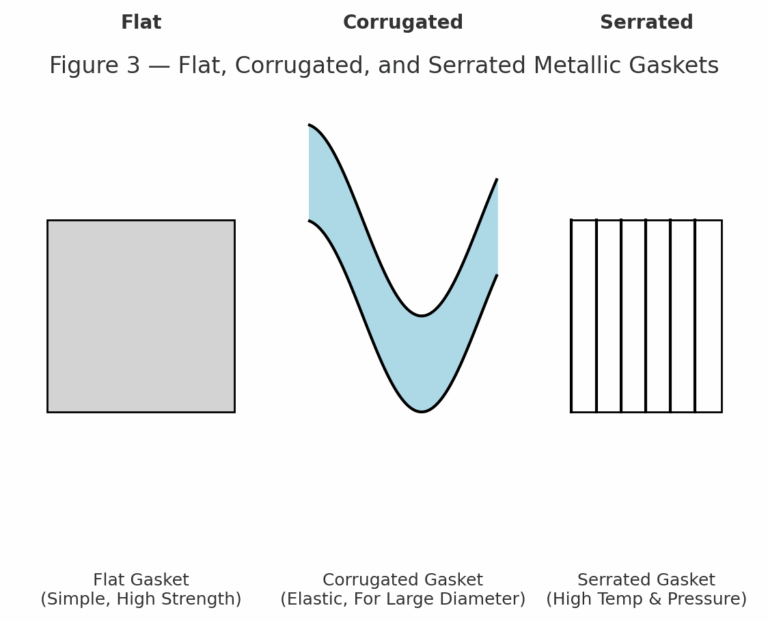

3.1 Flat Metal Gaskets

Good mechanical strength, suitable for medium- and high-pressure valves and pipelines.

Materials: soft iron, alloy steel, copper, aluminum. Selection depends on medium corrosion and operating temperature.

3.2 Corrugated Gaskets

Wave-shaped design provides elasticity and improved sealing compared with flat gaskets.

Suitable for large-diameter pressure vessels with moderate pressure fluctuations.

3.3 Serrated Gaskets

Machined with concentric grooves, offering reliable sealing under high temperature and pressure.

Maintain performance under high bolt preload. Widely used in medium- and high-pressure flanges.

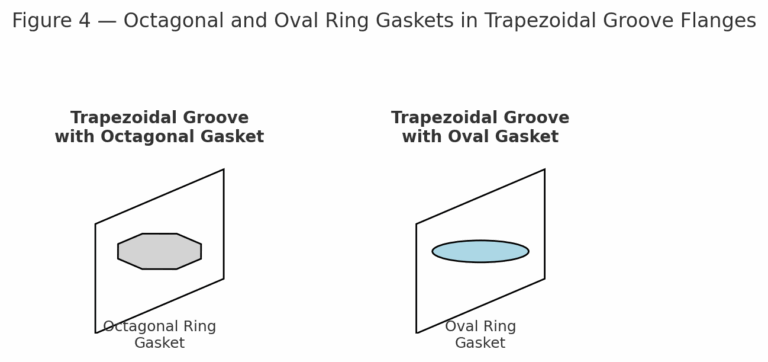

3.4 Octagonal and Oval Ring Gaskets

Designed for trapezoidal groove flanges.

Withstand high bolt preload and provide reliable sealing in high-pressure service.

Commonly applied in oil, gas, and petrochemical industries.

4. Metal Composite Gaskets

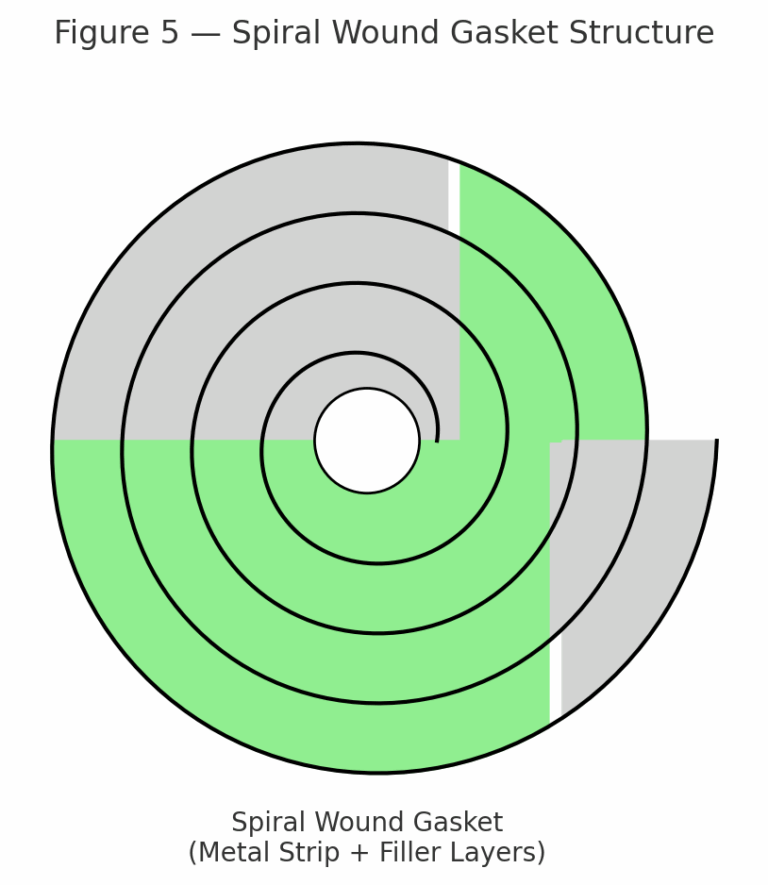

4.1 Spiral Wound Gaskets

Constructed from alternating layers of metallic strips (e.g., 304, 316 stainless steel) and non-metallic fillers (e.g., graphite, PTFE).

Combines the strength of metal with the compressibility and sealing ability of non-metallic materials.

Excellent resilience, suitable for fluctuating temperature and pressure environments such as petrochemical, power, and refinery industries.

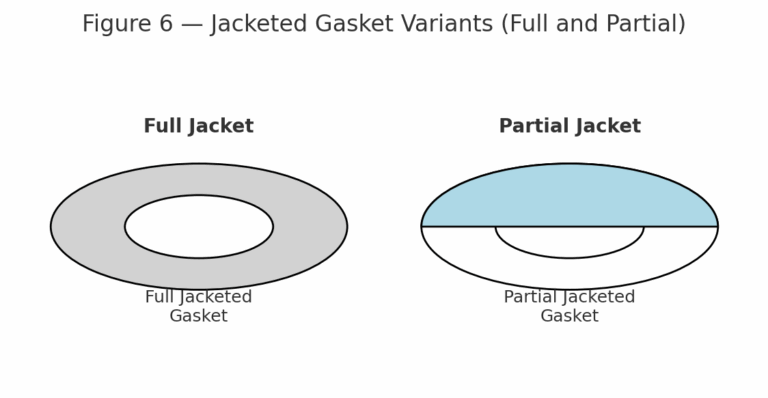

4.2 Jacketed Gaskets

Non-metallic filler core wrapped with thin metal sheet.

Types: fully jacketed or partially jacketed.

Suitable for higher temperature media. Can be manufactured in complex shapes for special chemical equipment and piping systems.

5. Comparative Table of Typical Gaskets

| Type | Temperature Range | Pressure Range | Suitable Media | Advantages | Limitations |

|---|---|---|---|---|---|

| Rubber | –60 to 150 °C | ≤1.6 MPa | Water, air, petroleum | Elastic, low cost | Aging, poor high-temp resistance |

| PTFE | ≤150 °C | ≤1.0 MPa | Strong acids/alkalis | Excellent corrosion resistance | Cold flow, creep |

| Asbestos Rubber | ≤200 °C | ≤2.0 MPa | Water, steam, inert gases | Low cost, easy use | Health risk, banned in many regions |

| Flat Metal | Up to 500 °C | High pressure | Oil, gas, steam | Strong, durable | Poor elasticity, needs high preload |

| Corrugated | Up to 500 °C | Medium pressure | Vessels, pipelines | Good resilience | Not for very high pressure |

| Serrated | Up to 600 °C | High pressure | Steam, hydrocarbons | Reliable at high preload | Requires precision machining |

| Spiral Wound | –200 to 600 °C | Up to 25 MPa | Oil, gas, chemical fluids | Excellent resilience, versatile | Higher cost |

| Jacketed | –50 to 500 °C | Medium-high | Chemical equipment | Strong + sealed, shape flexible | Manufacturing complexity |

6. Application Guidelines

Low-pressure water/air service: Rubber gaskets.

Highly corrosive media: PTFE gaskets or spiral wound with PTFE filler.

High-temperature, high-pressure flanges: Serrated, spiral wound, or ring gaskets.

Large-diameter pressure vessels: Corrugated gaskets.

Special shapes or higher temperature chemical service: Jacketed gaskets.

7. Conclusion

Choosing the right gasket is critical for safe and reliable chemical operations. Selection should consider medium characteristics, operating temperature, pressure, and flange type. Non-asbestos and advanced composite gaskets are increasingly favored due to safety and environmental concerns.