Instrument failures can be complex and difficult to diagnose immediately. It’s important to stay calm and analyze the situation step by step. The faults can generally be divided into three sections: on-site detection, intermediate transmission, and terminal display. Seasonal factors, such as preventing high temperatures in summer and freezing in winter, should also be considered. If there are abnormalities in the control parameters, first switch the regulator to manual mode and observe whether the issue lies within the control system, then proceed to check other possible causes.

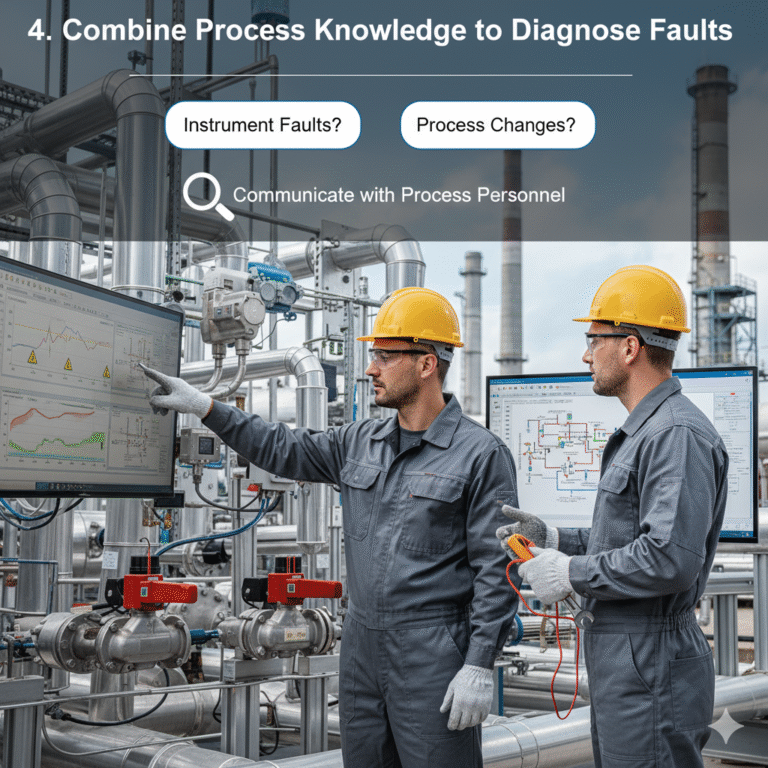

Before performing any maintenance, it is crucial to understand the working conditions and installation environment of the instrument. This includes knowing the instrument’s structural characteristics, performance, and whether it is associated with control and interlock functions. Always work with process personnel to determine the root cause of the issue while maintaining process stability during the repair process.

1. Temperature Instrument Faults and Troubleshooting

1.1 Sudden Increase in Temperature:

This is often caused by open circuits in the thermocouple or RTD, loose terminals, broken compensating wires, or faulty temperature sensors. Use a multimeter to measure resistance (in ohms) or millivolts at different points to quickly identify the issue.

1.2 Sudden Decrease in Temperature:

This is usually due to a short circuit in the thermocouple or RTD, shorted wiring, or sensor failure. Check common weak points such as connection terminals and bends in the wires.

1.3 Temperature Fluctuations or Rapid Oscillations:

In such cases, check the process operation and the associated control system. A fluctuating or unstable temperature could indicate issues with the process or the regulation system.

2. Pressure Instrument Faults and Troubleshooting

2.1 Sudden Pressure Drop or Increase:

This may occur due to blockages in the impulse tubing, valve blockages, or the presence of abnormal media within the impulse line. In cold weather, freezing of the media is also common. Check the impulse lines and root valves for any obstructions or leaks.

2.2 Large Pressure Fluctuations:

Fluctuations in pressure are often due to improper operation. Work with process personnel to investigate operational causes. Also, check the regulator settings and PID parameters if the pressure is part of a control system.

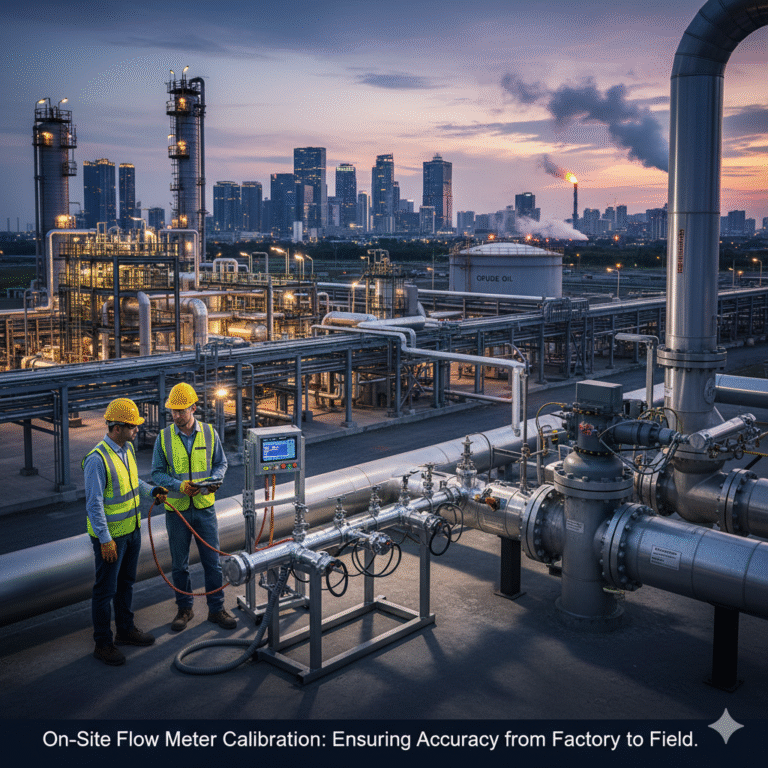

3. Flow Instrument Faults and Troubleshooting

3.1 Flow Indication at Minimum:

This could be due to damaged detection elements, low zero values, wiring issues, or problems with pressure chambers. Check for blockages or leaks in the system and verify if the flow regulator and associated control valves are functioning correctly.

3.2 Flow Indication at Maximum:

This issue is often due to blockage or leaks in the negative pressure chamber. A recalibration of the transmitter may not be necessary.

3.3 Flow Fluctuations:

When the flow measurement is not part of a control system, the issue may lie in the process. If it is controlled, check the PID settings and ensure that the pressure lines and isolation devices are free of air bubbles or other disturbances.

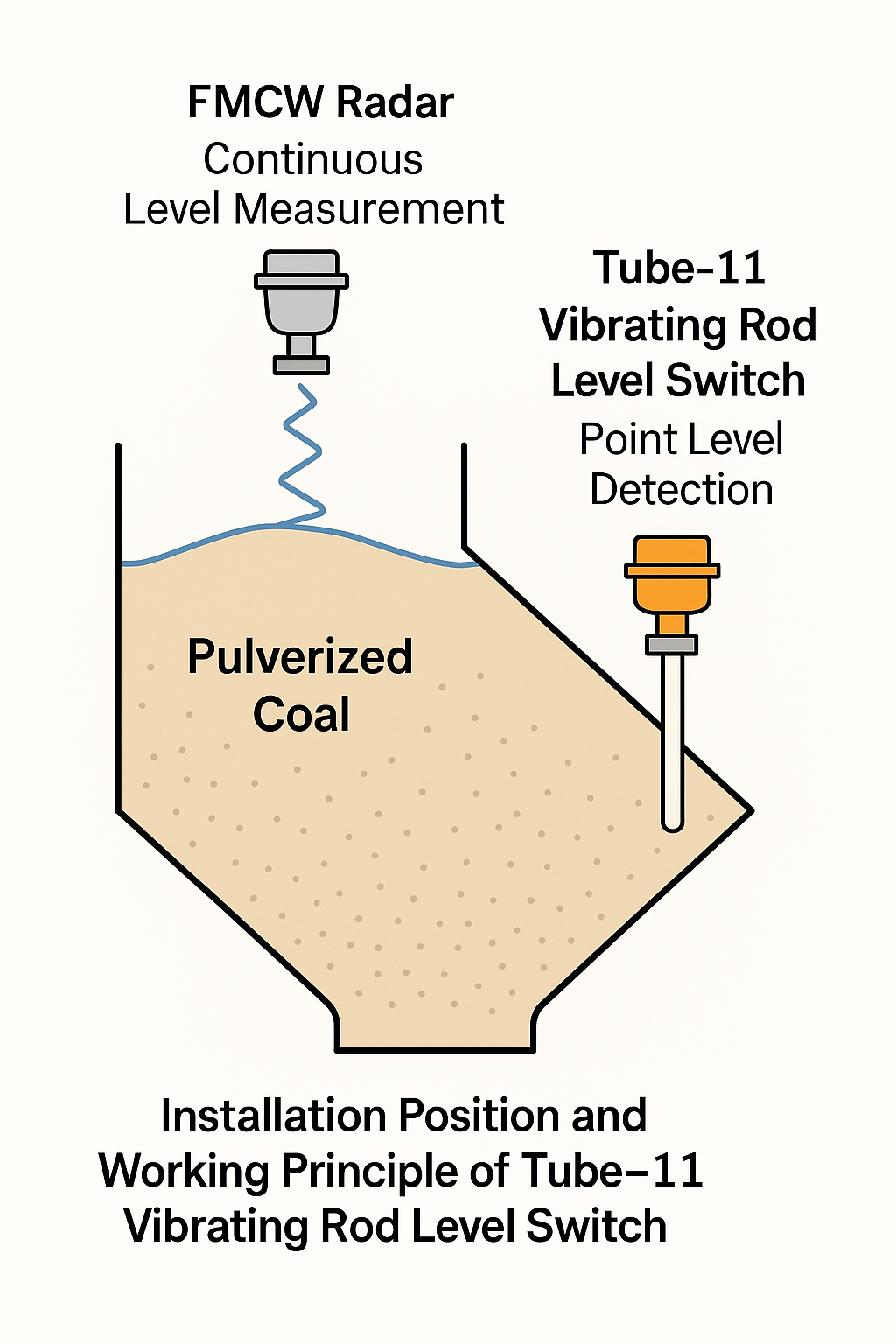

4. Liquid Level Instrument Faults and Troubleshooting

4.1 Sudden Increase in Level:

Check the negative pressure impulse system for blockages, leaks, or gas accumulation. To fix this, drain the system and refill it with the same medium, ensuring that the level indicator reads zero after adjustment.

4.2 Sudden Decrease in Level:

Check the positive pressure impulse system for blockages or leaks. If necessary, perform maintenance on the root valve or drain the system.

4.3 Inconsistent Readings Between Site and Central Control:

First, confirm whether the local level indicator is faulty by artificially adjusting the level and comparing it with the central control. If necessary, recalibrate or adjust the zero and span settings.

4.4 Frequent Level Fluctuations:

Collaborate with process personnel to check the feed and discharge conditions. Adjust PID parameters or manually adjust the setpoint and control valve to stabilize the level.

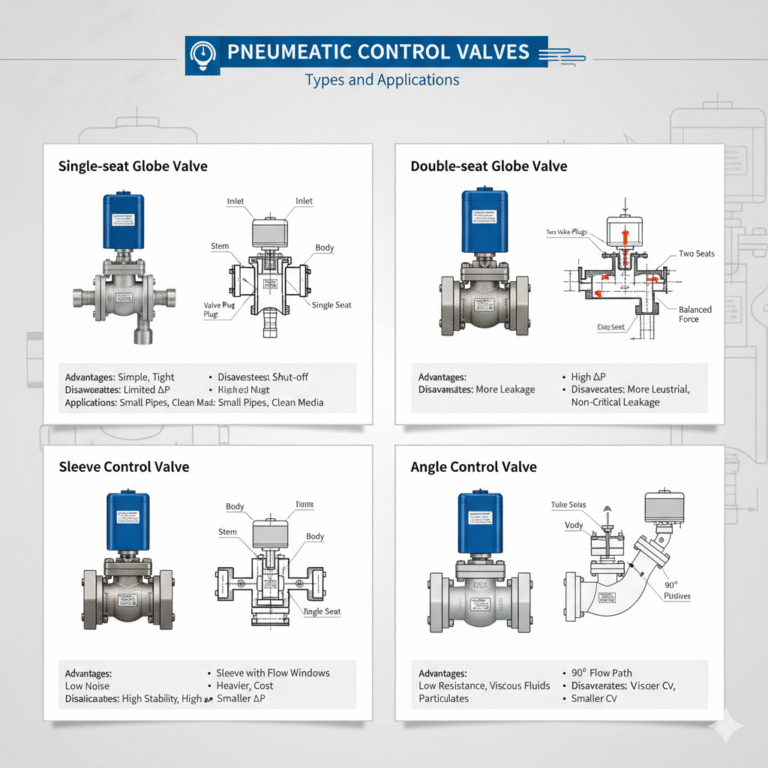

Common Valve Types and Faults

1. Exhaust Valve

This valve removes excess gas from the pipeline, improving pipeline efficiency and reducing energy consumption.

2. Diverting Valve

This valve splits, separates, or combines media within the pipeline.

3. Safety Valve

This valve prevents pressure from exceeding safe limits, providing safety protection.

4. Check Valve

This valve prevents backflow of media within the pipeline.

5. Shut-off Valve

This valve is used to start or stop the flow of media in the pipeline.

6. Regulating Valve

This valve adjusts parameters such as media pressure or flow rate.

Pneumatic Regulating Valve Faults and Troubleshooting

1. Lack of Signal or Air Supply:

Common causes include air source not being turned on, dirty air supply causing blockages, compressor failure, or air leaks.

2. Inconsistent Action or Instability:

Check if there are issues with the control signal pressure, such as fluctuating air supply or unstable signal pressure. Inconsistent valve movement may also be caused by dirt in the actuator or issues with the positioning components.

3. Vibration or Sluggish Action:

Vibration issues can be caused by unstable mounting, severe wear of valve seats, or incorrect valve sizing. Sluggish movement is often due to leaks in the actuator diaphragm or seal issues.

4. Leakage When Closed:

This is often due to valve seat wear, improper adjustment, or foreign objects within the valve body.