Introduction

Circuit breakers are critical components in electrical systems, designed to close, carry, and interrupt electrical currents under normal operating conditions and to disconnect the circuit during abnormal conditions like overloads, short circuits, or undervoltage. These devices are broadly classified into high-voltage and low-voltage circuit breakers. Generally, devices operating above 3kV are considered high-voltage.

Circuit breakers serve multiple purposes, such as distributing power, protecting circuits and motors, and safeguarding against severe electrical faults. Unlike fuse-based systems, circuit breakers often do not require component replacement after interrupting fault currents, making them widely used in modern electrical systems.

This article outlines common circuit breaker faults, analyzes their causes, and provides detailed handling methods to ensure safety and efficiency in electrical systems.

Common Faults and Handling Methods

1. Circuit Breaker Fails to Operate (Refusal to Act or Misoperation)

Fault Symptoms:

The circuit breaker does not respond when an operation command is issued.

The circuit breaker operates unintentionally without a command.

Cause Analysis:

Mechanical faults in the operating mechanism or transmission system.

Electrical control and auxiliary circuit faults.

Handling Steps and Methods:

Report the Issue: The on-duty personnel should report the situation to the supervisor or chief operator immediately.

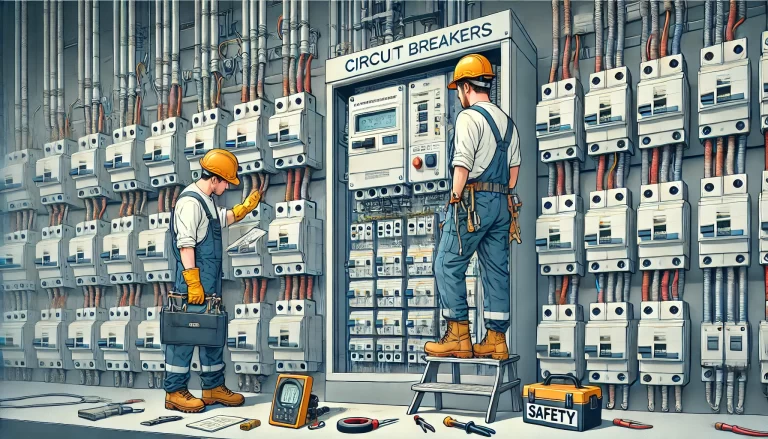

Preparation: Issue a work permit (type-1 work ticket), ensuring at least two members in the work group. Prepare tools such as a cross screwdriver, multimeter, socket wrench, fireproof clay, and insulating tape. Wear safety gear, including helmets, insulated shoes, and gloves.

Fault Detection and Resolution:

Mechanical Faults in Operating Mechanism and Transmission System:

Detection Method:

Check for jamming, deformation, or damage in the operating mechanism and transmission system.

Resolution:

Move the circuit breaker to the maintenance position manually and inspect for mechanical issues.

Repair damaged components carefully without applying excessive force to avoid further damage.

Electrical Control and Auxiliary Circuit Faults:

Detection Method:

Check for loose or faulty secondary wiring connections.

Inspect control circuit fuses for damage.

Examine the closing coil for burn marks or disconnection.

Check the functionality of auxiliary contacts.

Resolution:

Tighten loose connections.

Replace damaged fuses.

Replace burned-out closing coils.

Repair or replace faulty auxiliary contacts.

Post-Repair Activities:

Ensure the equipment returns to normal operation and organize tools.

Close the work permit and report completion to the supervisor.

2. Circuit Breaker Cannot Close Properly

Fault Symptoms:

The circuit breaker fails to engage when a closing command is issued.

Cause Analysis:

Mechanical faults in the operating mechanism or transmission system.

Electrical control and auxiliary circuit faults.

Handling Steps and Methods:

Report the Issue: Notify the supervisor or chief operator immediately.

Preparation: Follow the same preparatory steps as above, including work ticket issuance and tool preparation.

Fault Detection and Resolution:

Mechanical Faults in Operating Mechanism and Transmission System:

Detection Method:

Inspect for jamming, deformation, or wear in the mechanism.

Resolution:

Move the breaker to the maintenance position and identify the fault.

Conduct repairs without applying excessive force.

Electrical Control and Auxiliary Circuit Faults:

Detection Method:

Inspect secondary wiring connections for poor contact.

Check control circuit fuses for damage.

Test the closing coil for functionality.

Verify the state of auxiliary contacts.

Inspect connectors for alignment issues.

Resolution:

Tighten or replace faulty wiring.

Replace damaged fuses.

Replace malfunctioning coils or auxiliary contacts.

Post-Repair Activities:

Restore the circuit breaker to normal operation and clean up the site.

Report task completion.

Preventive Maintenance Recommendations

Under adverse operating conditions, such as unfavorable climates or corrosive environments, it is critical to shorten inspection and maintenance intervals. Key inspection tasks include:

Visual Inspection:

Check for unusual dust, debris, or signs of environmental damage. Ensure proper functioning of controls, interlocks, protection systems, and signaling equipment.

Contact Surface Inspection:

Inspect the condition of isolating contacts. If the silver plating is worn, corroded, or shows overheating (discoloration), replace the contacts immediately.

Accessory and Auxiliary Equipment Check:

Ensure no external discharge occurs at rated voltage. Detect signs like noise, ozone smell, or visible glow in the dark.

Routine Cleaning and Lubrication:

Clean dirt or grease from equipment surfaces using mild cleaning agents.

Tighten bolts in busbar and grounding systems.

Lubricate moving parts such as hinges, interlocks, and rolling mechanisms.

Functional Testing:

Test interlocking mechanisms, control circuits, and auxiliary contacts to verify proper functionality.

Add lubricants to areas showing wear.

By following these guidelines, the reliability of circuit breakers can be significantly enhanced, reducing the likelihood of unexpected faults and costly downtime.