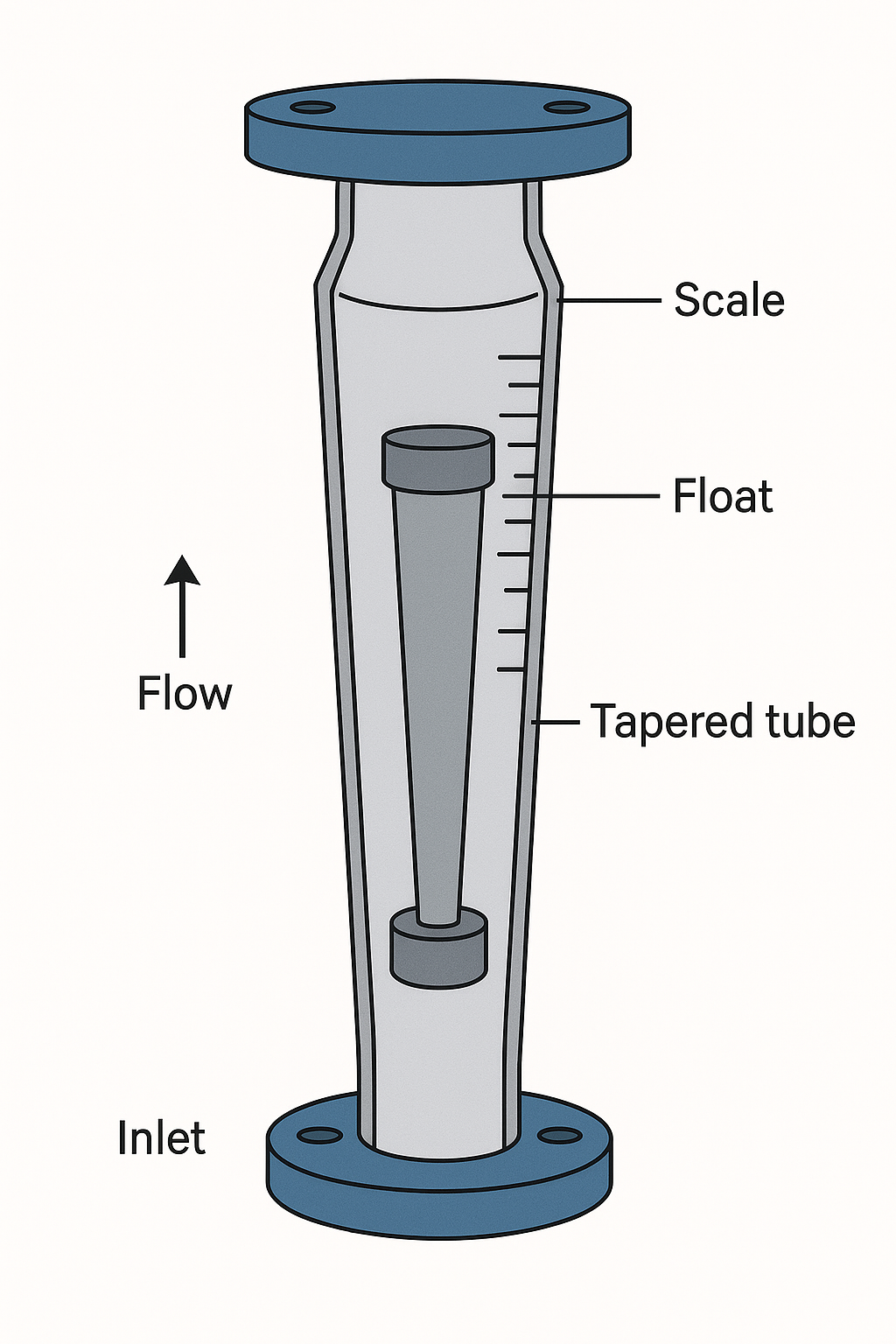

Variable area flow meters, commonly known as rotameters or float flow meters, are widely used in industrial applications for measuring the flow of liquids and gases. Their simple design, ease of installation, and low cost make them a popular choice. However, like all instruments, rotameters can experience operational issues. Understanding these issues, their causes, and appropriate solutions is crucial for ensuring accurate and reliable flow measurement.

1. Flow Indication Fluctuation or Instability

Potential Causes:

Presence of bubbles or impurities in the fluid: Gas bubbles or solid particles can disrupt the smooth movement of the float.

Pulsating flow: Caused by pumps or valves introducing unsteady flow patterns.

Improper installation position: Inadequate vertical alignment or excessive pipeline vibration.

Wear of the float or tapered tube: Long-term use leading to float sticking or irregular movement.

Solutions:

Install air vents or filters to remove gas bubbles and impurities.

Add dampers or flow stabilizers to minimize pulsation.

Ensure vertical installation with a maximum deviation of 5° from the vertical axis; reinforce piping if necessary.

Inspect and replace worn components as needed.

2. No Flow Indication or Zero Response

Potential Causes:

Float blockage: Accumulation of debris or deformation of the float.

No flow in the pipeline: Closed valve or pump failure.

Float damage or detachment: Mechanical shock or corrosion.

Transmitter failure (for electrical signal types): Damaged circuitry or disconnected signal cables.

Solutions:

Dismantle and clean the instrument; replace the float if damaged.

Check the status of valves, pumps, and pipelines to confirm flow.

Inspect the float for integrity and reassemble properly.

Test the electrical circuits and replace the transmitter if necessary.

3. Significant Deviation Between Indicated and Actual Flow

Potential Causes:

Changes in fluid density or viscosity: Process conditions differ from calibration settings.

Pressure or temperature variations: Deviations from design parameters.

Range mismatch: Flow exceeds the instrument’s specified measurement range.

Contamination of float or tapered tube: Scale formation or sediment affecting buoyancy.

Solutions:

Recalibrate the meter or select a model suited to the current fluid properties.

Install temperature and pressure compensation or adjust correction factors.

Replace the rotameter with one of an appropriate range.

Implement regular cleaning and maintenance schedules.

4. Float Does Not Rise or Moves Sluggishly

Potential Causes:

High fluid viscosity: Excessive resistance impedes float movement.

Bent guide rod or mechanical damage: Causes float to stick.

Corrosion of wetted parts: Leads to adhesion between float and tube walls.

Solutions:

Use a rotameter designed for high-viscosity fluids, such as models with guided floats.

Repair or replace deformed guide rods.

Select corrosion-resistant materials like stainless steel or PTFE-lined tubes.

5. Leakage Issues

Potential Causes:

Aging seals: O-rings or gaskets deteriorate over time.

Loose threaded or flanged connections: Vibration or improper installation.

Housing cracks: Overpressure or mechanical impact.

Solutions:

Replace all worn seals and gaskets.

Retighten connections and consider using thread sealant where appropriate.

Replace damaged housings and ensure protection against overpressure.

6. Abnormal Electrical Signal Output (Remote Transmitting Type)

Potential Causes:

Wiring errors or loose connections.

Faulty signal transmitter.

Unstable power supply.

Solutions:

Inspect and reconnect all wiring correctly.

Calibrate or replace the faulty transmitter.

Use a regulated power supply to ensure stable voltage.

Preventive Maintenance Recommendations

To minimize failures and extend the service life of rotameters:

Routine Cleaning: Prevent debris and scale accumulation in the flow tube and around the float.

Regular Calibration: Conduct recalibration every 6-12 months to ensure measurement accuracy.

Process Compatibility Check: Ensure that fluid properties (density, viscosity), temperature, and pressure remain within the meter’s design specifications.

Proper Installation: Maintain precise vertical alignment and provide support to avoid pipeline vibration.

Inspection of Seals and Connections: Periodically check for wear or leaks and replace components as needed.

Conclusion

By systematically diagnosing and addressing these common issues, engineers and technicians can ensure optimal performance of variable area flow meters. For complex operational conditions or persistent problems, consulting the manufacturer or qualified technical specialists is recommended.