Introduction

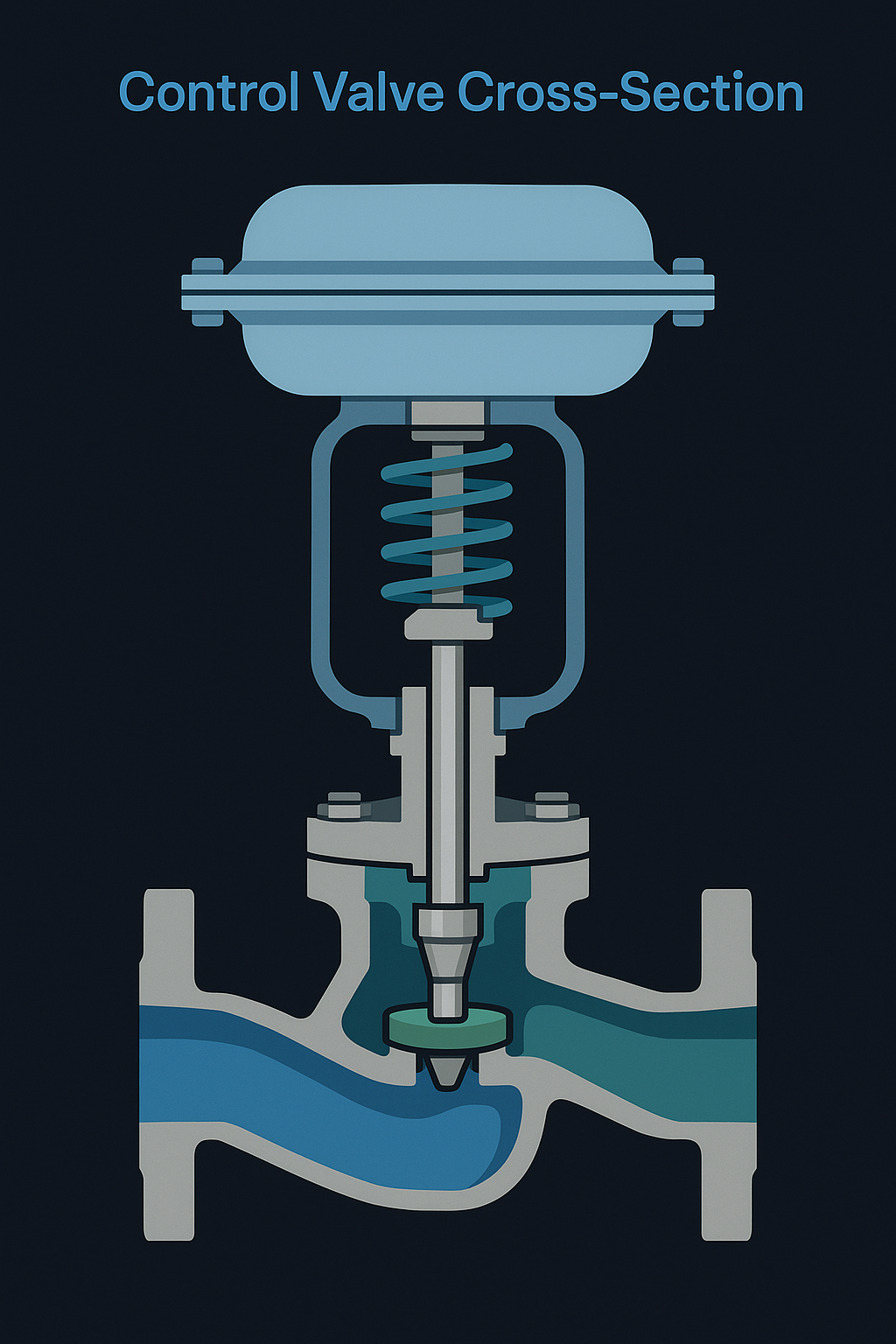

Pneumatic control valves play a crucial role in regulating process flow in industrial automation systems. However, due to complex operating environments and mechanical-electrical-pneumatic interactions, various faults may occur. This guide summarizes four common categories of failure, their causes, and practical troubleshooting methods.

1. Valve Fails to Actuate

Typical Symptoms: Valve does not respond to control signals.

Possible Causes:

Inadequate or interrupted air supply.

No output from I/P converter or positioner.

Diaphragm rupture inside actuator.

Sticking between valve plug and seat.

Troubleshooting Steps:

Air Supply Check

Ensure inlet pressure meets valve requirements (typically 0.4–0.6 MPa); inspect for blockage or leakage.Signal & Positioner

Measure input signal (e.g. 4–20 mA). If positioner has no output, recalibrate or replace it.Actuator Diaphragm

Dismantle actuator and inspect diaphragm. Replace if ruptured or aged.Valve Plug & Seat

Close inlet/outlet block valves, disassemble the trim, clean debris, and polish seating surfaces if needed.

2. Unstable Operation (Oscillation, Stick-Slip)

Typical Symptoms: Valve vibrates, responds sluggishly, or overshoots.

Possible Causes:

Fluctuating air pressure.

Improper positioner gain or tuning.

Poor lubrication between stem and guide bushing.

Foreign particles stuck in valve body.

Troubleshooting Steps:

Stabilize Air Pressure

Install a precision air regulator before the valve.Retune Positioner

Lower gain or adjust PID parameters to avoid hunting or overshoot.Lubricate Guide

Apply silicone-based grease to valve stem and bushing.Clean Internals

Flush valve body and install upstream filter if particles are frequent.

3. Leakage (Internal / External)

3.1 Internal Leakage

Symptoms: Valve is fully closed, but medium still flows.

Causes:

Damaged or worn sealing surface (plug/seat).

Dirt or debris on sealing surface.

Positioner zero offset – valve not fully closed.

Solutions:

Grind or replace trim: Restore plug/seat sealing surface.

Clean sealing areas: Remove any debris or scale.

Re-zero positioner: Ensure actuator delivers enough closing force.

3.2 External Leakage

Symptoms: Medium leaks from valve stem or flange.

Causes:

Packing material degraded or worn out.

Loose gland bolts.

Damaged flange gasket.

Solutions:

Replace packing: Use proper graphite or PTFE packing and compress layer-by-layer.

Tighten bolts: Evenly torque gland bolts to prevent misalignment.

Change gasket: Replace damaged gasket and retighten flange bolts using cross-tightening method.

4. Poor Control Accuracy

Symptoms: Valve cannot hold setpoint; process value fluctuates.

Possible Causes:

Inaccurate or degraded positioner.

Plug wear changes flow characteristics.

Damper failure (if equipped).

Signal interference (EMC issue).

Troubleshooting Steps:

Upgrade Positioner

Use high-accuracy smart positioner; recalibrate.Inspect Trim Wear

Replace plug if wear affects flow coefficient.Damper Check

Refill damping oil or replace damper assembly.Shield Signal Cable

Ensure twisted-pair shielded cables are grounded to reduce EMI.

Preventive Recommendations

| Inspection Item | Frequency | Action |

|---|---|---|

| Air supply pressure | Weekly | Check regulator stability |

| Positioner calibration | Monthly | Test signal response |

| Stem lubrication | Quarterly | Reapply approved grease |

| Packing tightness | Quarterly | Inspect for leaks and re-torque if needed |

| Gasket condition | Shutdown basis | Replace during major overhauls |

Conclusion

Effective maintenance and quick diagnosis of pneumatic control valve issues can significantly improve process stability and reduce downtime. By following the above troubleshooting steps and preventive measures, maintenance personnel can address most operational faults in a timely manner.