1. Introduction

Brief overview of vortex flowmeters

Key advantages in industrial flow measurement (e.g., low pressure loss, high accuracy, minimal maintenance)

Typical application areas: gas, steam, and liquid flow measurement in pipelines

2. Operating Principle of Vortex Flowmeters

Explain Kármán vortex street principle

Schematic diagram of vortex generation

Highlight how piezoelectric stress sensors work to detect vortex shedding

3. Installation Requirements

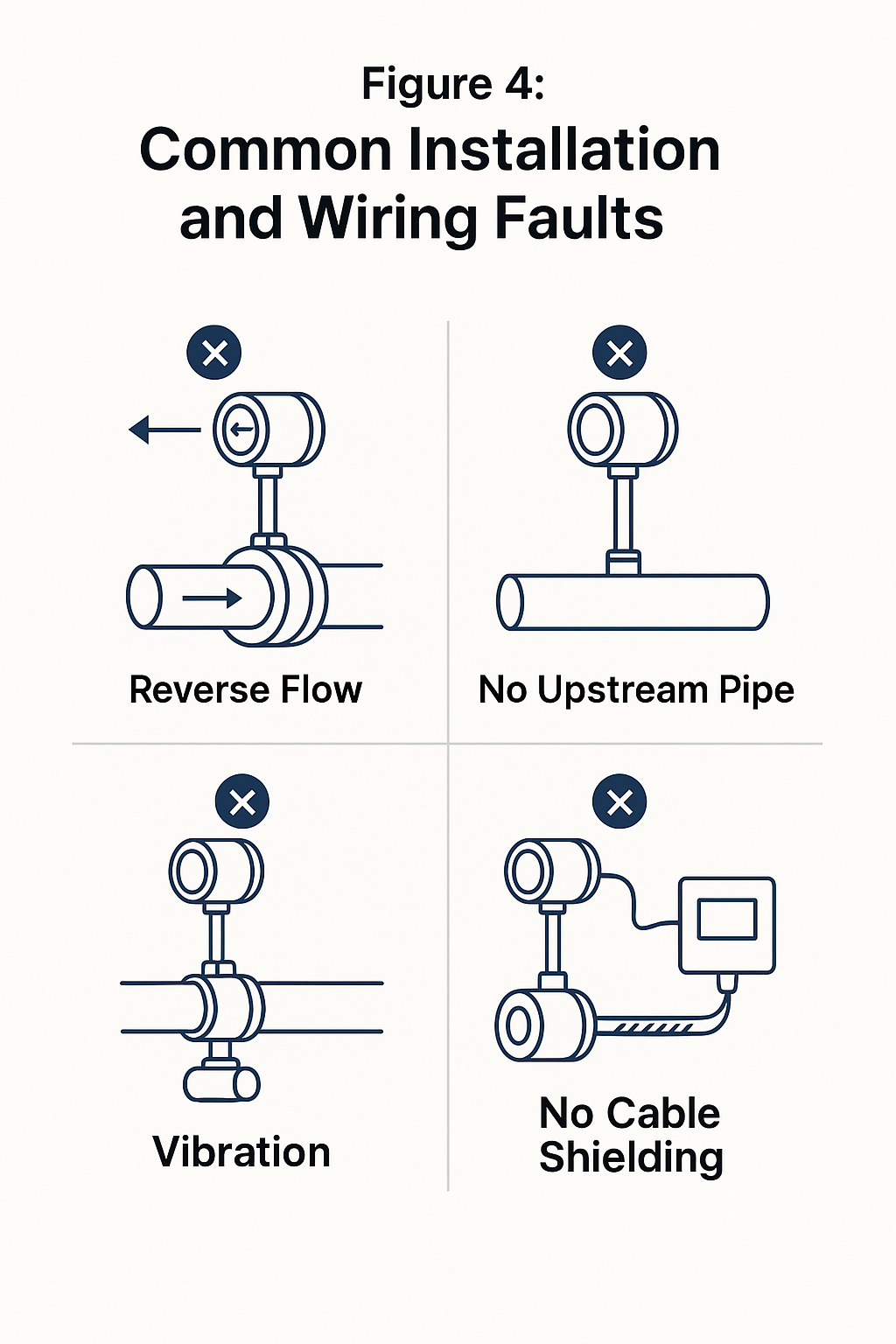

Environmental considerations: avoid strong electromagnetic interference, high heat sources, and vibration

Straight pipe requirements:

Same-plane double 90° elbows: upstream ≥ 25D, downstream ≥ 5D

Different-plane double 90° elbows: upstream ≥ 40D, downstream ≥ 5D

Control valve placement recommendations

Alignment and vibration damping measures

4. Common Failure Phenomena and Solutions

Each sub-section will describe:

Symptom

Cause analysis

Recommended solutions

📌 4.1. Large Flow Difference Despite Stable Display

Cause: Misconfiguration in PLC/DCS (e.g., unnecessary square root extraction)

Solution: Review and correct configuration

📌 4.2. Sudden Zero Reading at Low Flow

Cause: Oversized meter diameter or high cut-off threshold

Solution: Replace with smaller diameter vortex meter to enhance sensitivity (insert diagram showing relationship between flow and sensitivity)

📌 4.3. Significant Error at High Flow Rates

Cause: Vortex shedding instability leading to “signal dropout” or “leakage of vortex counts”

Solution: Replace with a meter of higher capacity (insert diagram illustrating vortex signal attenuation at high flow)

📌 4.4. False Flow Readings When No Flow Exists

Cause: Vibration or electromagnetic interference producing spurious signals

Solution: Install isolators, apply vibration dampening, and adjust sensitivity carefully

📌 4.5. Abnormal Fluctuations and Large Errors

Cause: Insufficient straight pipe length, pipe eccentricity, or presence of debris

Solution: Inspect installation and clean sensor probe (insert diagram of proper installation conditions)

📌 4.6. Inconsistent or Frozen Readings

Cause: Strong vibration or electromagnetic interference overpowering vortex signals

Solution: Improve shielding, use vibration isolation, or consider alternative measurement technologies

5. Key Recommendations for Field Engineers

Always verify lower and upper flow limits during selection (provide formula for density and vibration effects on lower limit)

Avoid using large diameter vortex meters for low-velocity flows

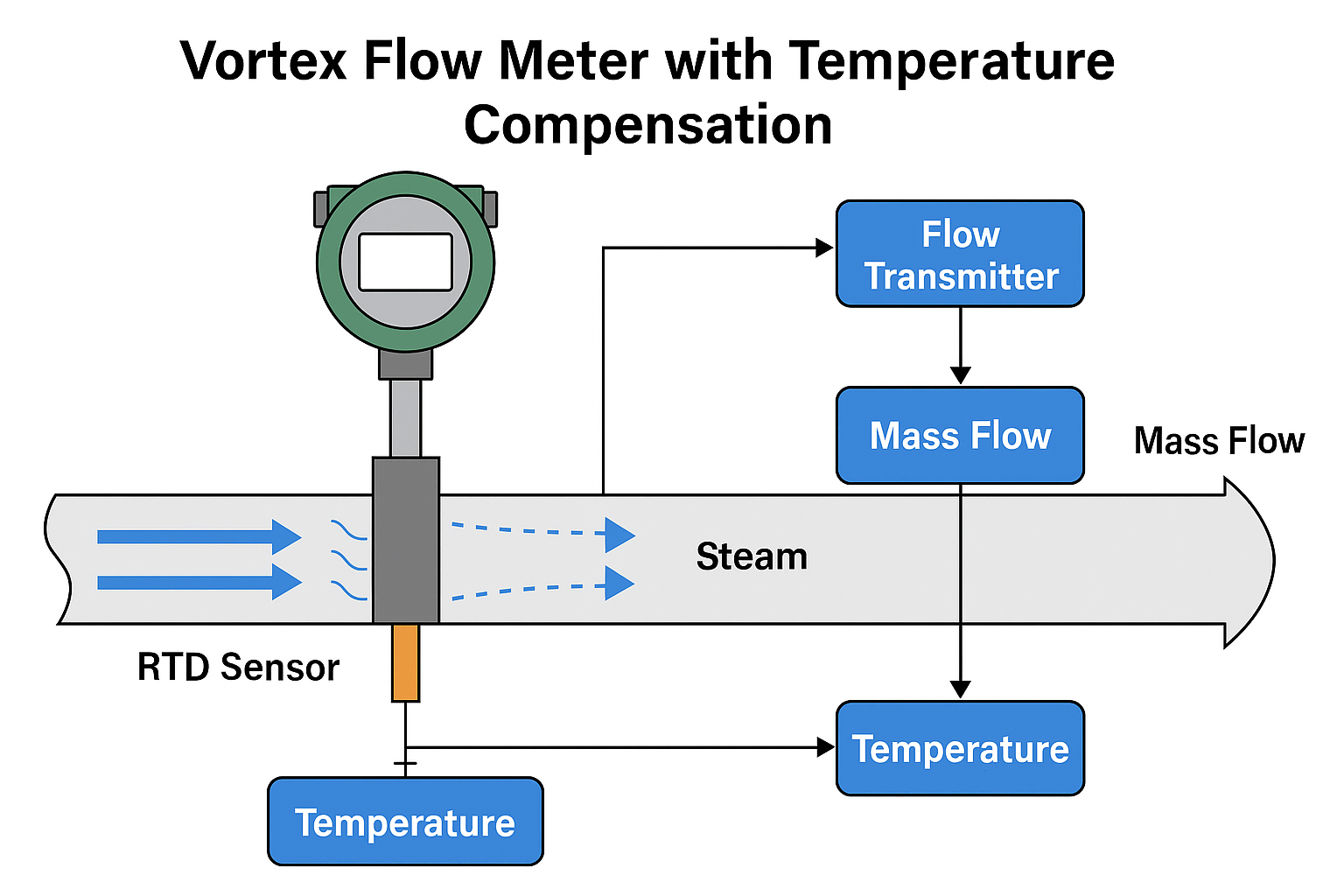

Caution on using built-in pressure sensors due to potential inaccuracies

6. Conclusion

Reinforce importance of correct sizing, installation, and configuration

Suggest preventive maintenance tips