Distributed Control Systems (DCS) are the backbone of modern industrial automation, responsible for real-time control, monitoring, and data acquisition. However, like all complex systems, DCS components can experience a variety of faults that may lead to process interruptions or safety risks. This article summarizes the most frequently encountered failures in DCS systems and provides practical guidance for diagnosis and mitigation.

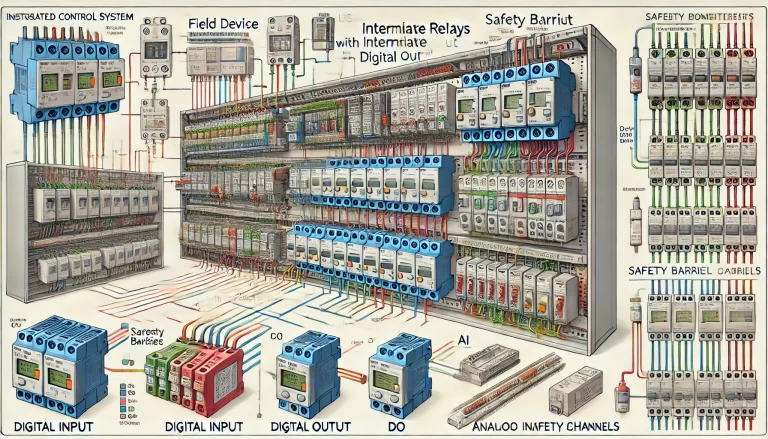

1. I/O Card Failures

Symptoms and Identification

I/O card failures are typically detected through system diagnostics. Symptoms include abnormal signal readings, channel loss, or communication errors.

Common Causes

Aging of internal electronic components

Connector failures or corrosion

Manufacturing defects

Troubleshooting and Resolution

Since most I/O cards are integrated modules, field-level maintenance is limited. In most cases:

Replace the card with a spare module

Swap channels (if supported)

Contact the manufacturer for component-level repair

⚠️ Note: Hot-swapping of cards should follow strict safety protocols, especially for digital input/output (DI/DO) modules, to prevent load or system fluctuations.

2. Operator Station Crashes (Freezing or Deadlock)

Typical Triggers

Hard disk or memory failure

Faulty expansion cards

Overloaded cooling fans

Human error during configuration or software uploads

Risks and Consequences

System crashes during control logic changes or forced signal operations can cause:

Abnormal system behavior

Unexpected shutdowns

Extended downtime during reboot (varies by manufacturer)

Recommendations

Avoid non-essential configuration during live operation

Ensure system backups and image recovery tools are in place

Use industrial-grade hardware with redundancy where possible

3. Unresponsive Control Operations

When operator inputs do not result in expected process changes, potential causes include:

Software defects: Faulty logic or unverified control schemes

Hardware malfunction: Unresponsive output channels or signal path disruptions

Resolution Strategy

Confirm process feedback signal path is functional

Test communication integrity between operator station and controller

Restart operator station if necessary

4. Power Supply Failures

Failure Modes

Blown fuses or incorrect fuse ratings

Failure of automatic switching between primary and backup power

Voltage fluctuations causing false protections or shutdowns

Loose or oxidized power terminals

Preventive Measures

Proper fuse selection according to load type

Use of UPS (Uninterruptible Power Supply) with redundancy

Dual power input modules where available

Scheduled power terminal inspection and maintenance

5. Electromagnetic Interference (EMI) and Signal Noise

Primary EMI Sources

Improper grounding of the DCS system

Switching of backup power supplies

High-frequency wireless devices (e.g., radios, mobile phones)

Interference from high-voltage or high-current equipment

Mitigation Strategies

Strict adherence to shielding and grounding standards

Maintain adequate spacing between signal cables and power sources

Use isolation modules for high-interference areas

Avoid using handheld radios near the engineer station or control modules

Avoid manual master-slave switching during normal operation unless necessary

Conclusion and Best Practices

While DCS systems are designed for high reliability, proper training, preventive maintenance, and incident analysis are key to minimizing downtime:

Train operators to record system behavior before and after any fault

Implement layered protection, including hardware redundancy and UPS

Collaborate with DCS vendors for firmware updates and system audits

Periodically test hot-swappable modules under safe conditions

By understanding and anticipating common failure modes, facilities can maintain stable operation, reduce unplanned shutdowns, and enhance system safety.