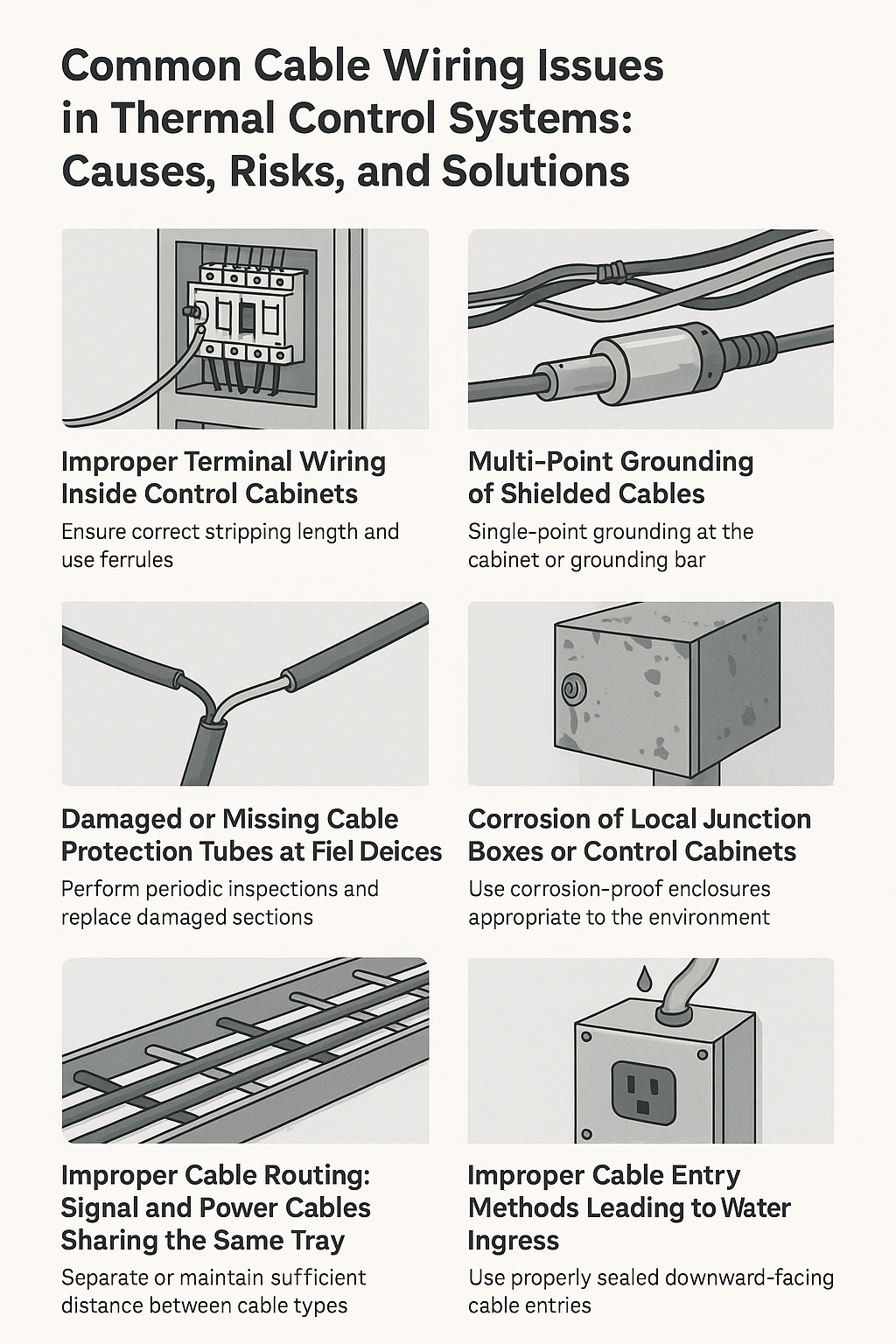

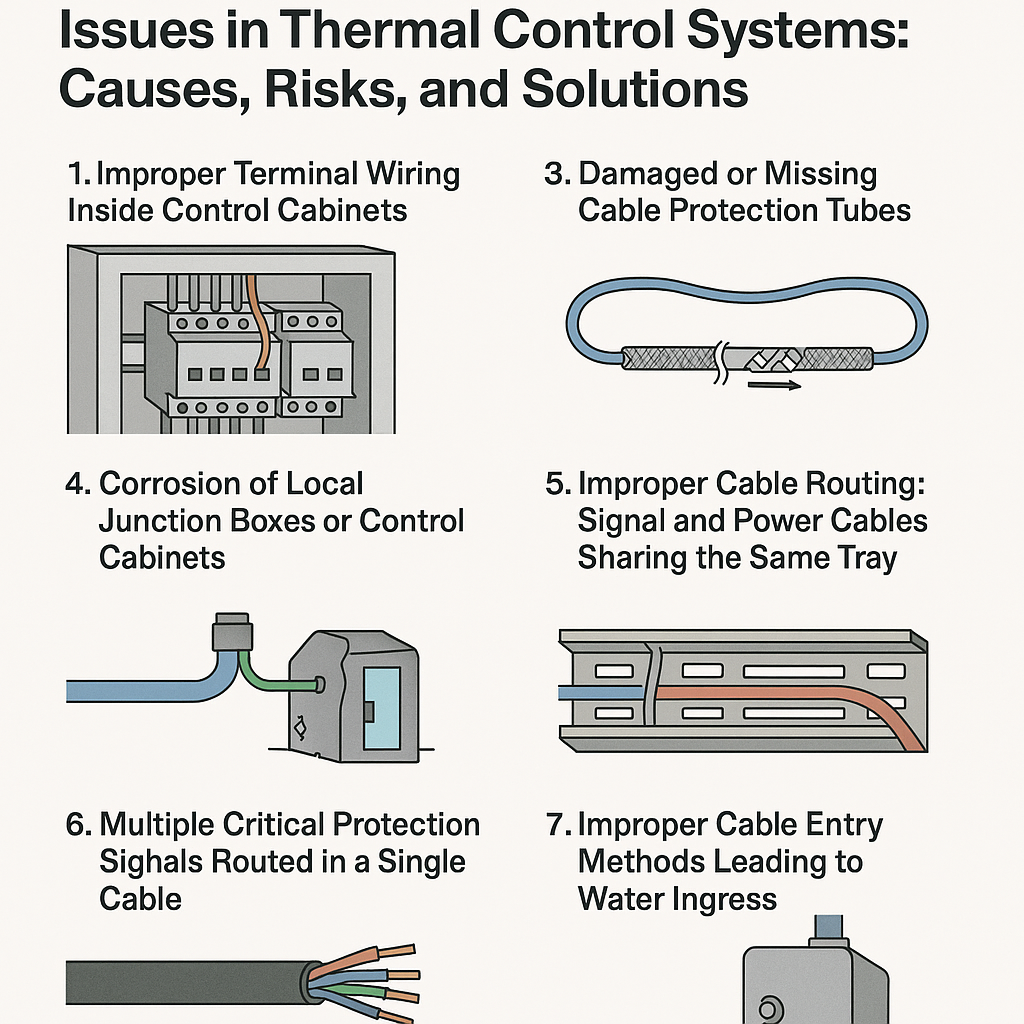

1. Improper Terminal Wiring Inside Control Cabinets

One common issue is excessive exposure of wire cores at terminal blocks. When conductors are stripped too long before termination:

The exposed wires can easily contact adjacent terminals or conductive surfaces, leading to signal short circuits.

Vibration or thermal expansion may loosen the connections, resulting in intermittent signal loss or equipment malfunction.

Recommendation:

Ensure stripping length is strictly controlled and in line with terminal specifications. Use ferrules or wire-end sleeves to enhance connection stability and safety.

2. Multi-Point Grounding of Shielded Cables

Shielded signal cables are designed to reduce electromagnetic interference (EMI). However, incorrect grounding methods can negate their effectiveness:

Problem: Grounding the shielding layer at multiple points creates a ground loop.

Consequence: Ground loops can introduce noise currents, leading to signal instability, false alarms, or inaccurate readings.

Recommendation:

Implement single-point grounding at the control cabinet or designated grounding bar. Ensure that cable shields are properly insulated at other points.

3. Damaged or Missing Cable Protection Tubes at Field Devices

In outdoor or harsh environments, signal cables are usually routed through protective tubes. However:

Protective tubing may fall off due to poor fixation or degradation over time.

Cracked or broken conduits expose cables to mechanical damage, UV radiation, moisture ingress, and rodents.

Recommendation:

Use UV-resistant, corrosion-proof tubing with appropriate fixing methods. Conduct periodic visual inspections and replace damaged sections promptly.

4. Corrosion of Local Junction Boxes or Control Cabinets

Exposure to moisture, chemicals, or salt-laden air can cause:

Rusting and corrosion of metallic enclosures.

Degradation of sealing gaskets, which allows further ingress of dust and water.

Consequence:

Signal integrity can be compromised, and internal components may short-circuit or fail prematurely.

Recommendation:

Use IP65-rated or higher stainless steel or coated enclosures for outdoor or corrosive environments. Add ventilation with desiccant filters where needed.

5. Improper Cable Routing: Signal and Power Cables Sharing the Same Tray

Mixing low-voltage signal cables and high-voltage power cables within the same cable tray can cause:

Electromagnetic coupling, especially in long parallel runs.

Temperature sensors and analog signals being affected by power line noise.

Recommendation:

Separate signal and power cables into different trays or maintain a minimum distance (typically >30 cm). Use shielded cables with twisted pairs and grounded shields for analog signals.

6. Multiple Critical Protection Signals Routed in a Single Cable

In an effort to reduce material costs, some installations bundle several safety-critical signals into one multi-core cable:

Risk: A single cable failure (e.g., open circuit, crush, water ingress) can simultaneously disable multiple protections.

Consequence: This may lead to process hazards or failure to initiate safety interlocks.

Recommendation:

Distribute critical signals across different cables or routes. Apply redundancy where necessary in safety-related systems.

7. Improper Cable Entry Methods Leading to Water Ingress

Cables entering enclosures without proper sealing measures can allow water to enter:

Entry points facing upward or lacking strain relief and sealing glands create a direct path for rainwater or condensation.

Water ingress degrades insulation, causes corrosion, and leads to potential short circuits.

Recommendation:

Use downward-facing cable entries with IP-rated glands or sealing bushings. Add water traps or sealing paste in high-humidity areas. Ensure cables form a “drip loop” before entering enclosures.

Conclusion

Thermal control systems operate in demanding environments and rely on precise, noise-free signals. Many hidden issues in wiring—if left unaddressed—can accumulate and cause significant downtime or hazards.

To prevent these risks:

Conduct routine inspections focused on cable routing, termination quality, and enclosure integrity.

Adhere to standardized wiring practices and apply preventive maintenance on a scheduled basis.

Consider environmental conditions when selecting materials and protective measures.

By addressing these common cable wiring issues, engineers and technicians can significantly enhance the reliability, safety, and maintainability of thermal control systems in industrial settings.