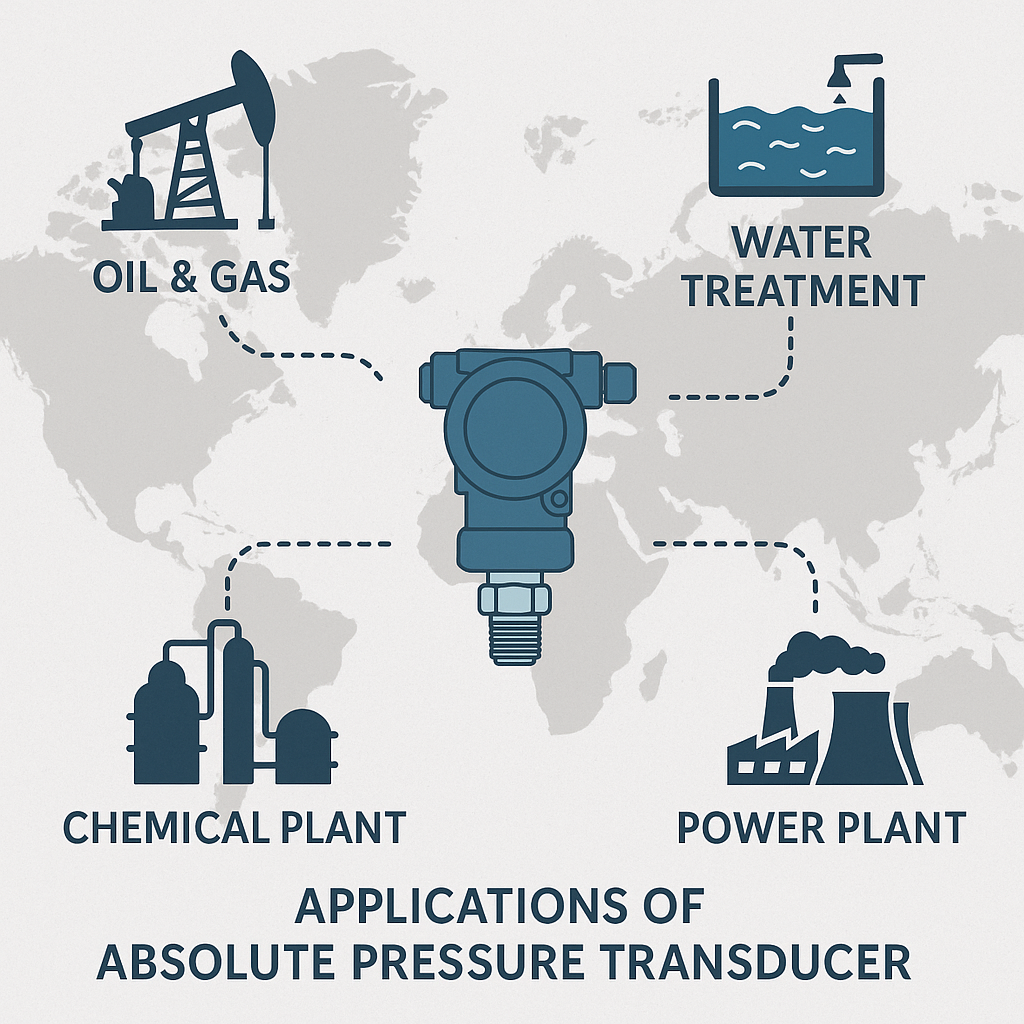

Pressure sensors, also known as pressure transducers, are devices that detect pressure changes in gases or liquids and convert these changes into standardized electrical signals. Based on their functional characteristics and application environments, pressure sensors can be categorized into several specialized types:

1. High-Temperature Pressure Sensors

These sensors are designed to operate reliably in elevated temperature environments. While standard pressure sensors typically support media temperatures from –40°C to +85°C, high-temperature pressure sensors can function in ranges from –40°C up to +150°C, depending on sensor construction and thermal isolation design.

Applications:

Steam pipelines

Engine systems

Industrial furnaces

Oil & gas processing lines with elevated temperatures

2. Explosion-Proof Pressure Sensors

Explosion-proof pressure sensors comply with intrinsic safety standards and are suitable for use in hazardous areas where explosive gases or vapors are present. These sensors are designed to prevent ignition from sparks or surface temperatures under normal and fault conditions.

Typical Certifications: Ex ia IIC T4 Ga / ATEX / IECEx

Hazard Zones: Zone 0, Zone 1, Zone 2

Applications:

Petrochemical plants

Refineries

LNG terminals

Underground mines

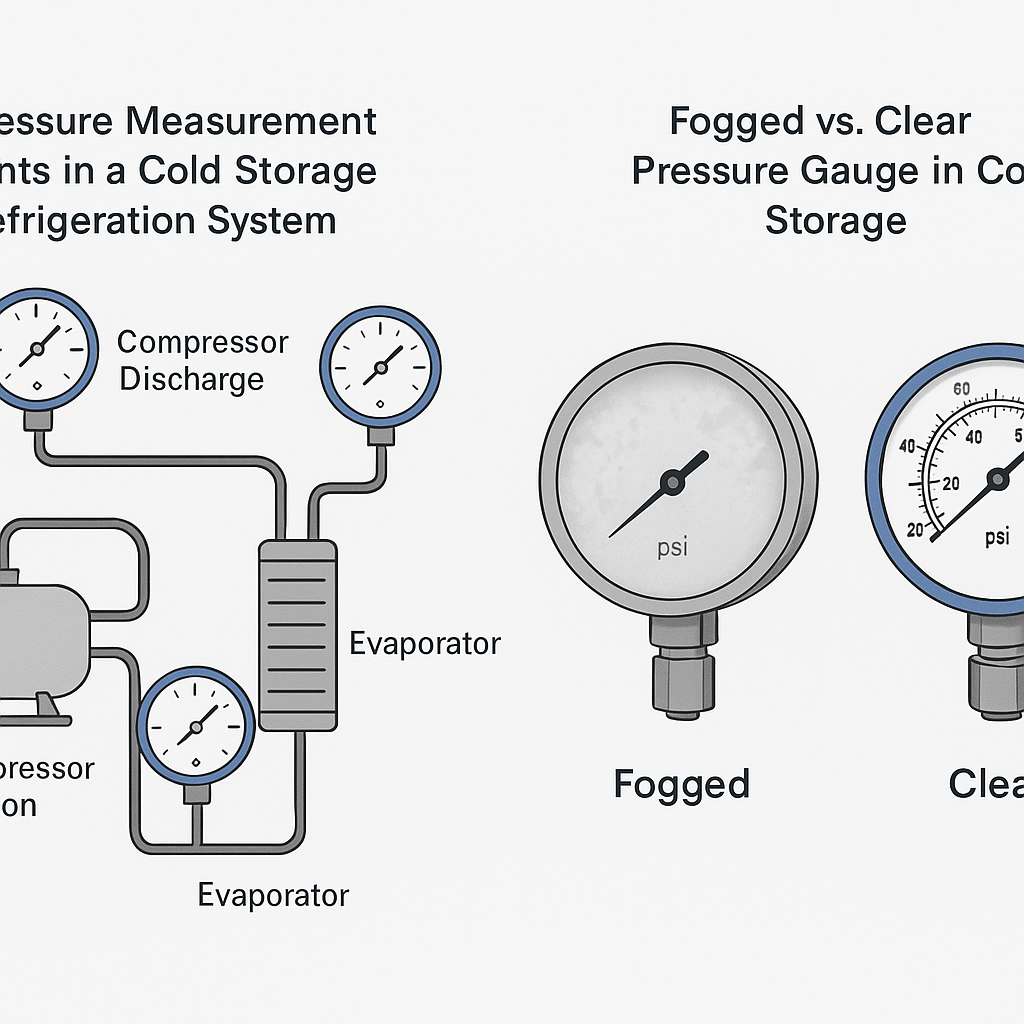

3. Waterproof Pressure Sensors

Waterproof sensors are engineered for continuous immersion and harsh outdoor environments. Models rated IP68 offer the highest level of water and dust protection. Their hermetically sealed structure ensures long-term stability and corrosion resistance.

Applications:

Submersible liquid level monitoring

Hydrology and water treatment

Marine and underwater equipment

4. Shock-Resistant Pressure Sensors

Shock-resistant models are designed for high-impact environments. They feature rugged mechanical structures that can withstand:

Vibration

Sudden high-pressure surges

Particle impact (e.g., sand, cement)

Abrasive slurry conditions

Applications:

Oilfield cementing and fracturing

Construction machinery

Concrete pumping systems

Hydraulic test rigs

5. Sanitary Pressure Sensors

Sanitary pressure sensors are constructed from 316L or 316K stainless steel, with polished surfaces and flush diaphragms, allowing for easy cleaning and sterilization. They comply with hygienic standards and are compatible with CIP/SIP processes.

Applications:

Food and beverage production

Pharmaceutical processing

Dairy and brewing industries

Bioreactors and fermentation tanks

6. Union-Type (Hammer Union) Pressure Sensors

These sensors adopt a hammer union connection and are designed to withstand harsh drilling and fracturing conditions. The sensing diaphragm is robust and resistant to erosion, making the sensor suitable for high-pressure, high-frequency impact environments.

Key Features:

Compact mechanical structure

High vibration resistance

Erosion-resistant diaphragm

Fast installation and replacement

Applications:

Cementing operations

Hydraulic fracturing

Wellhead monitoring

Geotechnical grouting systems

Conclusion

Pressure sensors are among the most widely used instruments in industrial automation. Choosing the right type of sensor based on functional requirements such as temperature tolerance, explosion protection, water ingress resistance, mechanical durability, sanitary design, or specific connection type is crucial for ensuring accurate, safe, and reliable measurements across various industries.