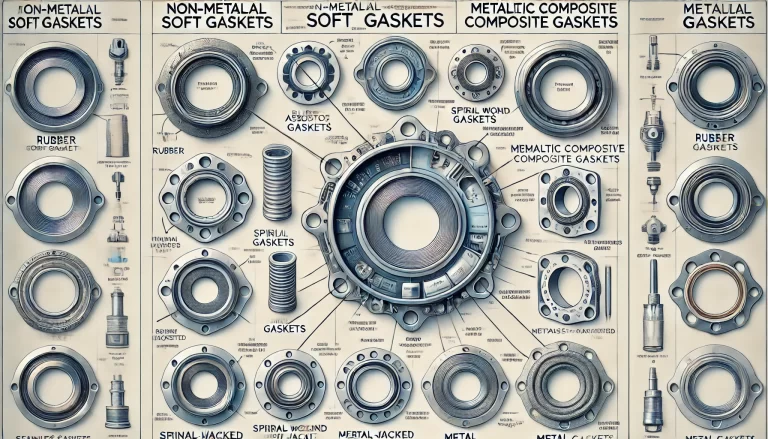

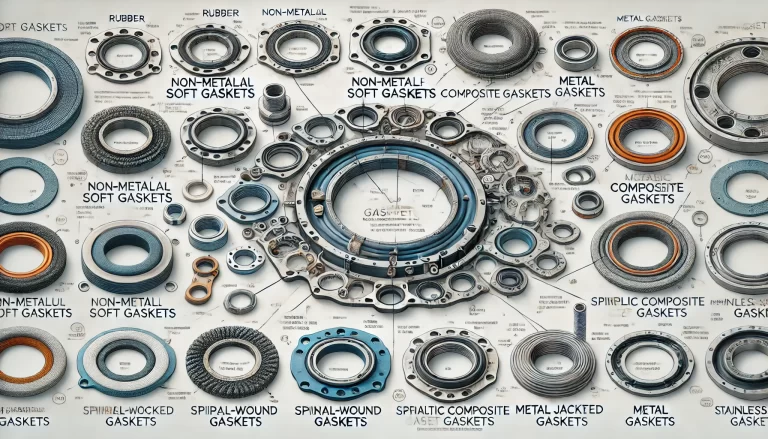

The selection of gaskets for instruments depends on specific application scenarios, including factors such as temperature, pressure, and the type of medium. Choosing the right gasket is crucial for ensuring the sealing performance and reliability of the instrument. Based on material, common gaskets for instruments are classified into three main categories:

1. Non-Metallic Soft Gaskets

These gaskets are made from materials such as rubber, asbestos rubber, non-asbestos fiber rubber, polytetrafluoroethylene (PTFE), and PTFE-coated gaskets. They are characterized by their flexibility, corrosion resistance, and affordability. However, they have relatively low resistance to high temperatures and high pressures, making them suitable for sealing flanges in low- and medium-pressure containers or pipelines at normal or moderately elevated temperatures.

Common Types:

- Rubber Gaskets: Suitable for low-temperature and low-pressure environments, offering excellent flexibility and sealing properties.

- PTFE Gaskets: Resistant to most chemicals, with superior anti-corrosion properties, but limited to environments below 150°C.

- Asbestos Rubber Gaskets: Affordable and moderately durable, commonly used in medium-temperature and pressure conditions.

- Non-Asbestos Fiber Gaskets: A safer alternative to asbestos, offering similar performance without health risks.

2. Metallic Composite Gaskets

Metallic composite gaskets combine the strength and resilience of metal materials with the sealing capabilities of soft fillers. They are suitable for high-pressure and high-temperature environments.

Common Types:

- Spiral Wound Gaskets: Composed of alternating layers of metal and soft fillers, these gaskets are ideal for applications with stress relaxation, temperature fluctuations, or vibration.

- Metal-Toothed Composite Gaskets: Provide exceptional sealing performance in demanding conditions such as frequent pressure and temperature changes.

- Metal-Jacketed Gaskets: Combine a metallic outer layer with a soft filler core, offering good adaptability and durability in medium- to high-pressure systems.

Key Advantages:

- High-temperature and high-pressure resistance.

- Excellent sealing under stress cycling and mechanical vibrations.

- Durability in environments with corrosive mediums.

3. Metal Gaskets

Metal gaskets, such as copper and stainless steel gaskets, are engineered for extreme conditions, including high temperatures, high pressures, and frequent load cycles. These gaskets provide superior sealing, corrosion resistance, and mechanical strength.

Common Materials:

- Annealed Copper Gaskets: Suitable for temperatures up to 800°C and pressures ranging from 2 MPa to 42 MPa. Annealing prevents cracks and ensures a tight seal.

- 304 and 316 Stainless Steel Gaskets: Ideal for medium-temperature applications (up to 760°C), offering high corrosion resistance and anti-creep properties.

Limitations:

While metal gaskets excel in sealing performance and durability, they are more expensive compared to non-metallic gaskets.

Performance of Common Gasket Materials Under Different Conditions

1. Temperature and Pressure Ranges:

- Asbestos Paperboard or Aluminum Foil Gaskets: Perform well below 80°C and 2 MPa but are unsuitable for high-temperature and high-pressure environments.

- PTFE Gaskets: Excellent for low-temperature (<150°C) and corrosive conditions, though unsuitable for high temperatures.

- Graphite Gaskets: Handle high temperatures (>150°C) effectively, but their sealing performance may diminish under extreme pressures.

- High-Temperature Metal-Jacketed Gaskets: Designed for use in equipment exceeding 1000°C, although they may have issues with internal graphite filler degradation.

2. Specific Applications:

- Spiral Wound Gaskets: Used in applications where there is significant temperature or pressure cycling.

- Nylon Gaskets: Offer good elasticity and recovery for moderately high-temperature and pressure applications but are unsuitable for extreme conditions.

Recommendations for Application

When selecting gaskets, consider the following factors:

- Operating Temperature and Pressure: Ensure the gasket material can withstand the specified conditions without failure.

- Medium Compatibility: Choose materials resistant to the chemical properties of the medium.

- Frequency of Load Cycles: For frequently changing load conditions, opt for metal or composite gaskets with high resilience.

- Cost Considerations: While metal gaskets are superior in performance, non-metallic gaskets can be a cost-effective solution for less demanding environments.

Conclusion

The selection of gaskets plays a pivotal role in the reliability and safety of instrumentation systems. By understanding the properties of different gasket materials and their application scenarios, engineers can make informed decisions to optimize system performance and ensure longevity.

Figures and Tables

To enhance comprehension, diagrams of gasket types and a comparative performance table for various materials can be included (not available in this text version).