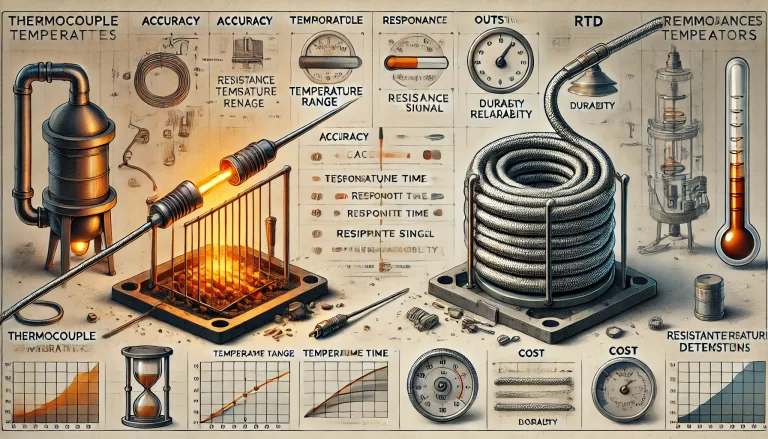

When selecting a temperature sensor for a specific measurement location, the choice between Resistance Temperature Detectors (RTDs) and thermocouples is crucial. Each type has distinct characteristics that make it suitable for different applications. Below is a detailed comparison to help you make the best decision.

What Are RTDs and Thermocouples?

RTDs (Resistance Temperature Detectors): These sensors measure temperature by correlating the resistance of a material (typically platinum) with temperature. They are known for their accuracy and stability.

Thermocouples: These sensors generate a voltage based on the thermoelectric effect, where two dissimilar metals produce a voltage proportional to the temperature difference between their junctions.

Key Characteristics of RTDs

Temperature Range:

- RTDs operate effectively between -200°C and 500°C, with some models extending to 600°C.

- They are ideal for low to medium temperature ranges.

Accuracy:

- RTDs are highly accurate, often with deviations of less than ±0.1°C for high-quality models.

- Their precision makes them suitable for applications where even minor temperature variations need to be monitored.

Stability and Reliability:

- RTDs exhibit excellent long-term stability, with minimal drift over time.

- This makes them particularly suitable for monitoring processes requiring consistent accuracy over months or years.

Linearity:

- The relationship between temperature and resistance in RTDs is almost linear, simplifying calibration and data interpretation.

Response Time:

- RTDs tend to have slower response times compared to thermocouples because their design typically includes thicker materials for durability.

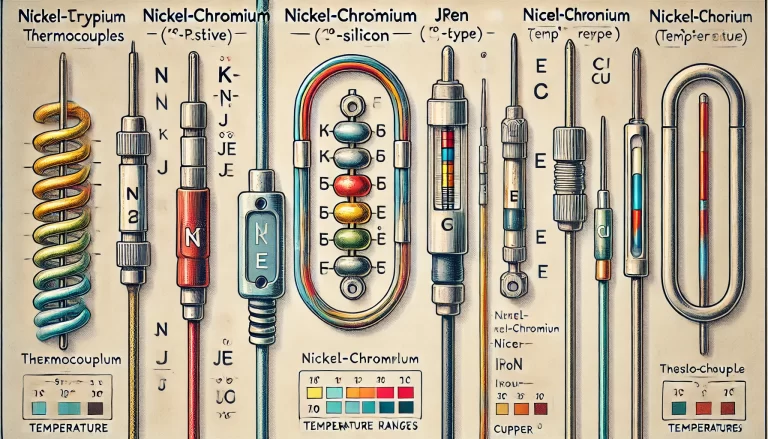

Key Characteristics of Thermocouples

Temperature Range:

- Thermocouples cover an extensive temperature range, from -200°C to 1800°C, depending on the type (e.g., Type K, J, T, etc.).

- They are the preferred choice for high-temperature environments.

Response Time:

- Thermocouples respond quickly to temperature changes due to their simple and thin design.

- This makes them ideal for applications with rapid temperature fluctuations.

Durability in Harsh Environments:

- Thermocouples are robust and can withstand extreme conditions such as high vibration, corrosive environments, and rapid temperature changes.

Nonlinearity:

- Unlike RTDs, thermocouples have a non-linear voltage-to-temperature relationship.

- This requires additional signal processing, often involving lookup tables or polynomial equations.

Sensitivity to Noise:

- Thermocouples generate low-voltage signals, which can be prone to electrical noise. Proper shielding and signal amplification are often necessary.

Comparison Table

| Criteria | RTDs | Thermocouples |

|---|---|---|

| Temperature Range | -200°C to 500°C (some up to 600°C) | -200°C to 1800°C |

| Accuracy | High (±0.1°C for high-quality models) | Moderate |

| Response Time | Slower | Faster |

| Stability | Excellent | Moderate (subject to drift) |

| Durability | Limited to moderate environments | Suitable for harsh conditions |

| Cost | Higher initial cost | Lower initial cost |

| Linearity | Nearly linear | Nonlinear |

| Maintenance | Minimal | Regular calibration needed |

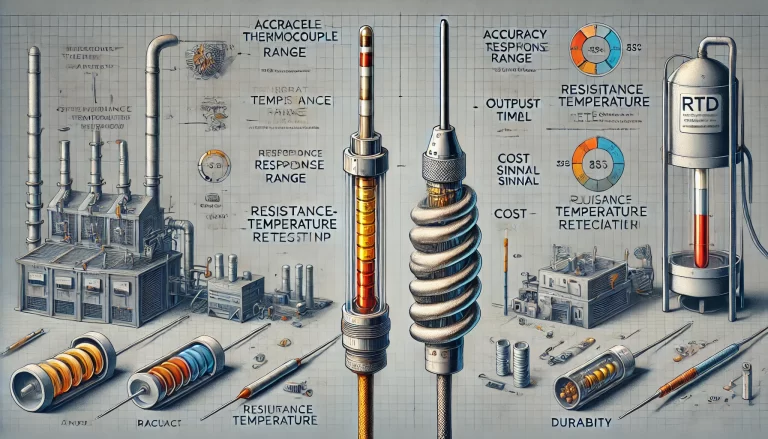

When to Choose RTDs

RTDs are best suited for:

- Low to Moderate Temperature Applications: RTDs excel in environments with temperatures below 500°C, such as in HVAC systems or laboratory setups.

- High Precision Requirements: If accuracy and stability are critical, RTDs are the ideal choice.

- Long-Term Monitoring: For processes requiring consistent temperature measurements over extended periods, RTDs provide reliable performance.

When to Choose Thermocouples

Thermocouples are ideal for:

- High-Temperature Applications: They are the go-to choice for industries like metalworking, glass production, and high-temperature furnaces.

- Dynamic Temperature Changes: Their fast response time makes them suitable for processes with rapidly changing temperatures.

- Harsh Environments: Thermocouples are more resilient to extreme conditions, such as high vibration, corrosive atmospheres, and pressure variations.

- Budget-Conscious Applications: With their lower cost, thermocouples are often used in applications where precision is secondary to cost efficiency.

Practical Considerations

Environmental Conditions:

- RTDs work best in clean, controlled environments.

- Thermocouples are preferred for rugged, industrial settings.

Signal Processing Needs:

- RTDs require minimal processing due to their linear response.

- Thermocouples need amplification and compensation for nonlinearity and noise.

Installation and Maintenance:

- RTDs have a higher initial cost but lower maintenance requirements.

- Thermocouples are cheaper initially but require regular calibration to maintain accuracy.

Conclusion

The choice between RTDs and thermocouples depends on the specific needs of your application. If you prioritize accuracy, stability, and moderate temperature ranges, RTDs are the better option. However, for high-temperature environments, quick response times, or cost-sensitive applications, thermocouples are the ideal solution. Carefully assess your operational conditions, budget, and measurement requirements to make the right choice.