01 Main Content of Chemical Process Flow Design

The design of the chemical process flow is completed through various stages, including the Process Block Diagram (PBD), simplified Process Flow Sketch (PFS), and Process Flow Diagram (PFD).

Process simulation calculations, along with material and energy balances, are performed to ensure accurate process design and efficiency.

Equipment design and selection based on process requirements and technical specifications.

Determining the primary control schemes for the process.

Defining the “three wastes” (waste gas, waste water, and waste residue) treatment and comprehensive utilization strategies.

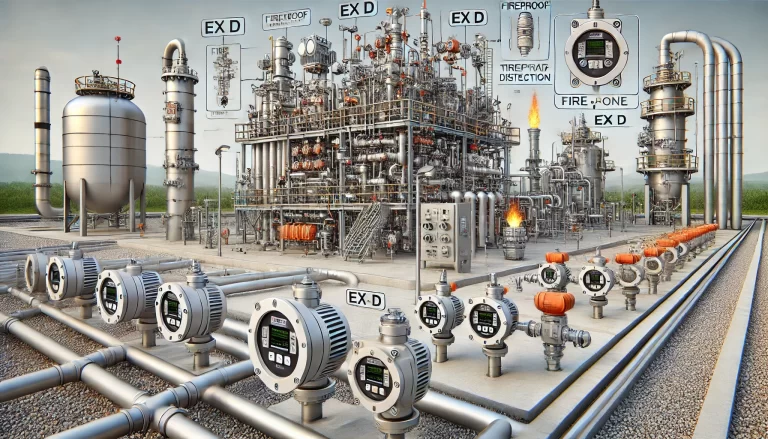

Preliminary process safety analysis.

02 Example of Chemical Process Flow Design

2.1 Basic Conditions for a 100,000-ton/Year Isobutene Unit Separation and Product Refining Process Design

Production Capacity: 100,000 tons per year of polymer-grade isobutene.

Product Specifications: Isobutene content >99.7% (by mass).

Reaction Byproduct: Temperature of 400°C and pressure of 0.1 MPa.

2.2 Basic Process Analysis

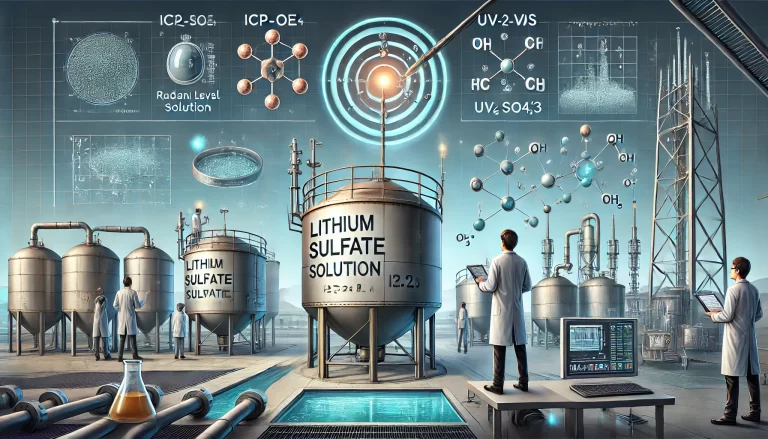

The reactants are primarily composed of light hydrocarbons (C1–C4) and contain trace amounts of organic oxygenated compounds.

The process separation is divided into two major sections:

Depropane Process for Reaction Products: The high-temperature reaction products are first subjected to heat recovery and water quenching to bring them to ambient temperature, then compressed before entering the depropane process. Separation is achieved based on boiling point differences among components, using either an oil absorption method or cryogenic method (this example uses the cryogenic method).

Separation of Isobutene and Product Refining from C4 Fraction: The C4 fraction in this case consists of 7 components, including C2 and C3 fractions. These components have distinct boiling points, and conventional distillation methods are used to separate the isobutane fraction first, followed by the separation of isobutene and 1-butene fractions. Other C4 fractions are sent out as by-products.

The separation of isobutene/1-butene is particularly challenging due to the small boiling point difference (only 0.6°C). As a result, conventional distillation cannot achieve effective separation, and methods such as catalytic distillation or MTBE (methyl tertiary-butyl ether) are used to obtain qualified isobutene products.

2.3 Process Block Diagram (PBD)

Based on the process analysis, the Process Block Diagram (PBD) is created, as shown below. The block diagram outlines the main operational units and material flows in the process, providing a preliminary overview of the process for determining the fundamental process scheme.

2.4 Process Flow Sketch (PFS)

The Process Flow Sketch (PFS) is a semi-schematic diagram that serves as a more refined version of the Process Block Diagram (PBD). While it retains a diagrammatic form, it is commonly used in the early stages of design for discussing and reviewing the proposed process flow.

2.5 Process Simulation Flow Diagram (PSFD)

The Process Simulation Flow Diagram (PSFD) is developed from the Process Flow Sketch (PFS) and is used for process simulation calculations. It serves as an intermediate product between the process flow design and the simulation results, evolving as the process design progresses.

The main process flow is continuously refined and optimized.

Key equipment names, types, and technical data are included.

Thermal exchange networks and the design of cooling and heating systems are established based on raw material and product heating/cooling requirements.

Material transportation and gas pressurization equipment are incorporated into the design.

PSFD forms the foundation for the detailed PFD design.

2.6 Process Flow Diagram (PFD)

After the process simulation is completed, the simulation flow diagram is transformed into a full Process Flow Diagram (PFD). This diagram must represent the names, numbers, and operating conditions of process equipment, along with the thermal loads for industrial furnaces and heat exchangers, the main process control interlocks, and logistics data tables. It combines graphical elements (PFD) with tabular data (logistics data tables), serving as a comprehensive tool for the process design.

03 Chemical Process Flow Design and Technological Development

Innovative thinking and high standards are essential for advancing chemical process flow design and driving chemical technology development. Chemical process flow design is the core of process design, and the PFD, logistics data tables, and equipment lists form the three key components of the process design. Starting from these elements, equipment and process system designs are completed to form the comprehensive process design package.

Chemical production processes are centered around the main chemical reactions. New chemical reaction processes and catalysts often lead to major advances in chemical processes. These innovations typically emerge from professional research institutions, universities, and technical development departments within companies. Engineering firms play a critical role in the design of reactors, reaction systems, and the integration of technological advancements in raw material pretreatment and product separation and refinement processes.