Diaphragms are vital components in instruments and gauges, especially those used for measuring pressure, flow, and liquid levels. They function as sensitive elements that respond to the physical changes in their environment and convert these changes into measurable signals. Due to their importance, the materials, design, and construction of diaphragms need to meet several critical requirements. This article explores the key characteristics of diaphragms used in instrumentation, focusing on factors that make them indispensable for accurate and reliable measurements.

1. Corrosion Resistance

Diaphragms often come into contact with various fluids and gases, many of which can be corrosive. In industries like chemical processing, petrochemicals, and pharmaceuticals, corrosive substances such as acids, alkalis, or other aggressive fluids are common. The material of the diaphragm must resist corrosion to prevent degradation over time, which would otherwise compromise the accuracy of the measurements or lead to equipment failure.

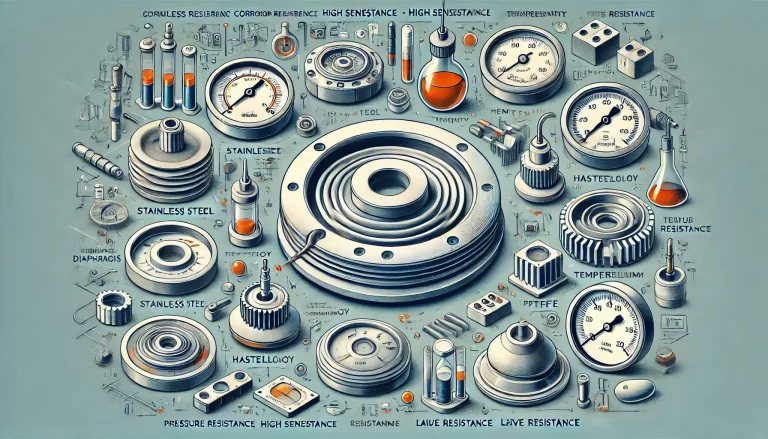

Common materials used for diaphragms include:

- Stainless Steel (304, 316): Widely used due to its good corrosion resistance and mechanical properties.

- Hastelloy: Known for its excellent corrosion resistance, particularly in highly aggressive environments.

- Titanium: Ideal for handling highly corrosive chemicals and seawater.

- PTFE (Teflon): Often used as a coating for diaphragms in extremely aggressive chemical environments.

The choice of material depends on the specific operating environment and the chemical compatibility with the process medium.

2. High Sensitivity

Diaphragms must exhibit high sensitivity to detect and respond to minimal changes in pressure or force. This characteristic is crucial for accurate measurement and control in systems that require precision. A well-designed diaphragm can detect very small variations in pressure, enabling it to be used in low-pressure environments or with delicate measurements.

To achieve this sensitivity, the diaphragm’s thickness and material are carefully selected. A thinner diaphragm is generally more sensitive but may be less durable, while a thicker diaphragm offers greater durability but at the cost of sensitivity. The trade-off between sensitivity and durability is one of the key considerations in diaphragm design.

3. Temperature Resistance

In many applications, diaphragms are exposed to extreme temperatures, either from the process medium or the external environment. They must withstand these conditions without significant loss of performance.

- High-Temperature Resistance: In industries like steam generation or oil refining, diaphragms are exposed to high temperatures, sometimes exceeding 500°C (932°F). In such cases, special alloys or high-temperature-resistant materials like Inconel or ceramics may be used to maintain performance.

- Low-Temperature Resistance: Conversely, in cryogenic applications, diaphragms may need to operate at extremely low temperatures, as low as -200°C (-328°F). Materials like stainless steel or specialized elastomers are often employed in such cases.

Temperature extremes can cause materials to expand or contract, affecting the diaphragm’s performance. Thus, materials need to have low thermal expansion and stable mechanical properties across a wide temperature range.

4. Fatigue Resistance

Diaphragms are often subjected to continuous cycles of pressure fluctuations, which can lead to mechanical fatigue over time. The ability to endure repetitive loading without undergoing permanent deformation or failure is critical for long-term reliability.

Fatigue resistance is typically enhanced by:

- Using high-quality alloys that resist mechanical fatigue.

- Precision engineering to reduce stress concentrations.

- Surface treatments that improve the material’s strength and longevity.

In applications such as aerospace or power generation, where diaphragms may experience millions of pressure cycles over their lifetime, fatigue resistance becomes even more critical.

5. Optimized Thickness and Elasticity

The thickness and elasticity of a diaphragm play a crucial role in its performance. The thickness affects both the diaphragm’s sensitivity to pressure changes and its mechanical strength.

- Thinner diaphragms provide higher sensitivity because they flex more easily under lower pressures. However, they may have a shorter lifespan and are more susceptible to damage from over-pressurization.

- Thicker diaphragms are more robust and can withstand higher pressures without deformation. However, they may be less sensitive to small pressure changes and slower in responding to rapid fluctuations.

Elasticity is also important because it determines how quickly the diaphragm returns to its original shape after being deformed by pressure. A diaphragm with the right balance of elasticity can provide faster and more accurate readings while maintaining durability.

6. Low Hysteresis

Hysteresis refers to the difference in the diaphragm’s response during the application and removal of pressure. Low hysteresis is desirable because it means that the diaphragm will return to its original position without delay or discrepancy, ensuring more accurate measurements.

In applications where precision is key, such as laboratory testing or pharmaceutical manufacturing, low hysteresis ensures that the instrumentation provides reliable, repeatable results.

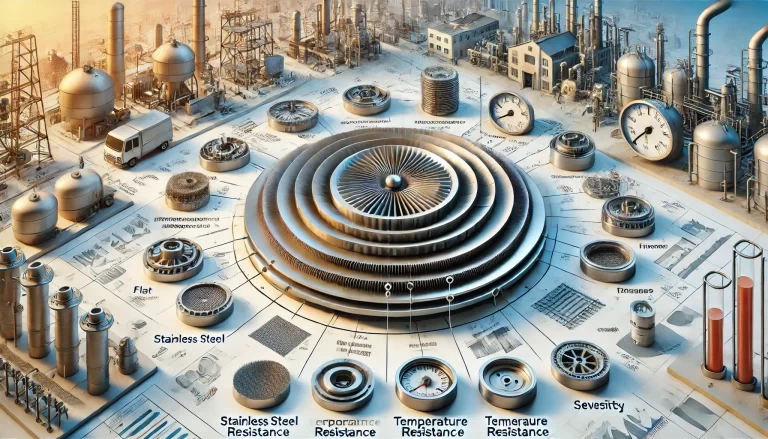

7. Versatility in Design and Application

Diaphragms come in various shapes, sizes, and configurations depending on the specific requirements of the instrument and application. They can be flat, corrugated, or even multi-layered to enhance their sensitivity and durability. In some designs, diaphragms are supported by backings or intermediate layers to provide additional strength or improve performance in extreme conditions.

Additionally, diaphragms are used in a wide range of instruments, including:

- Pressure Gauges: To measure pressure differences across a barrier.

- Flow Meters: In certain types of meters, diaphragms detect pressure changes caused by fluid flow.

- Level Sensors: For detecting the liquid level in tanks or containers by responding to the hydrostatic pressure of the liquid.

The design flexibility makes diaphragms suitable for a broad range of industries, from oil and gas to food processing and healthcare.

Conclusion

Diaphragms are crucial components in precision instruments, offering a combination of sensitivity, durability, and resistance to environmental stresses. Their performance characteristics, such as corrosion resistance, temperature tolerance, fatigue resistance, and minimal hysteresis, make them suitable for various demanding industrial and commercial applications. The careful selection of materials, design, and construction ensures that diaphragms provide accurate and reliable measurements over extended periods, even in harsh conditions. As technology advances, diaphragms continue to evolve, meeting ever more complex challenges in modern instrumentation.