1. Introduction

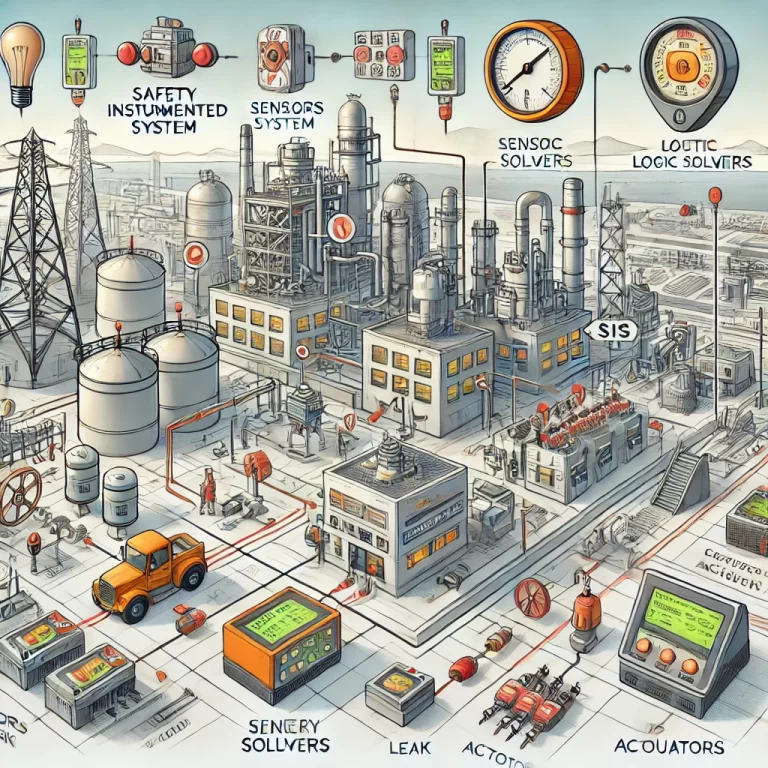

Chemical plants deal with hazardous materials, including flammable, explosive, toxic, and corrosive substances. This makes safety a top priority in these facilities. One of the key safety measures in place is the Safety Instrumented System (SIS), which is designed to prevent or mitigate hazardous events by taking automatic protective actions.

A well-designed SIS must ensure high reliability, rapid response, and independence from process control systems. To achieve these objectives, redundancy configurations are widely adopted to enhance the system’s resilience against failures. This article explores the key characteristics of SIS in chemical plants and discusses various redundancy configurations to ensure optimal performance.

2. Key Characteristics of Safety Instrumented Systems (SIS)

2.1 High Reliability

SIS must operate under extreme conditions with high stability. The system should be designed using robust industrial-grade hardware and software that comply with international safety standards such as IEC 61508 (Functional Safety of Electrical/Electronic/Programmable Electronic Safety-related Systems) and IEC 61511 (Safety Instrumented Systems for the Process Industry Sector).

2.2 Real-Time Operation and Rapid Response

SIS is responsible for detecting unsafe conditions in real time and triggering protective actions, such as emergency shutdown (ESD), pressure relief, or alarm activation. The response time must be within the limits necessary to prevent accidents.

2.3 Independence from Process Control Systems (PCS)

SIS operates separately from the Process Control System (PCS) or Distributed Control System (DCS) to ensure that control system failures do not compromise safety functions.

2.4 Layered Safety Protection

Safety protection in chemical plants follows a layered approach, where SIS serves as an essential layer of defense beyond alarms, process control, and mechanical relief systems. The design of SIS is based on Safety Integrity Level (SIL), which defines the level of risk reduction required for different hazards.

2.5 Redundant and Fault-Tolerant Design

To prevent system failures from leading to hazardous events, redundancy configurations (e.g., 1oo2, 2oo3) are used. Redundant architectures ensure the system remains operational even if some components fail.

2.6 Self-Diagnosis and Maintainability

Modern SIS includes self-diagnostic capabilities, which allow the system to monitor sensor health, logic solver status, and final control elements. This improves reliability and facilitates predictive maintenance.

2.7 Lifecycle Management

SIS design follows a structured lifecycle approach, which includes hazard and risk assessment, system design, installation, operation, and continuous improvement. Compliance with IEC 61511 ensures that SIS remains effective throughout its operational life.

3. Redundancy Configurations in SIS

3.1 Importance of Redundancy

Redundancy is a crucial design element in SIS that ensures continued operation even when individual components fail. Different redundancy configurations offer varying levels of safety, availability, and fault tolerance.

3.2 Common Redundancy Architectures

The most commonly used redundancy configurations in SIS include:

| Configuration | Description | Pros | Cons |

|---|---|---|---|

| 1oo1 (One out of One) | Single-channel system where failure leads to loss of function. | Simple, low cost | Low reliability, not recommended for critical applications |

| 1oo2 (One out of Two) | Two independent channels; failure in any one triggers safety action. | High reliability, fault tolerance | More false trips compared to 2oo2 |

| 2oo2 (Two out of Two) | Both channels must detect a fault before triggering a response. | Reduces false trips | Lower availability, higher risk of failure |

| 2oo3 (Two out of Three) | Three channels; safety action triggered when two detect failure. | High reliability, reduced false alarms | More complex, higher cost |

| TMR (Triple Modular Redundancy) | Three fully redundant systems with voting logic. | Maximum reliability, used in SIL 3+ systems | Expensive, complex maintenance |

3.3 Selection Criteria for Redundancy

When choosing a redundancy configuration, the following factors must be considered:

SIL Requirement:

SIL 1: 1oo1 or 1oo2 configurations

SIL 2: 1oo2, 2oo3 recommended

SIL 3: 2oo3 or TMR required for critical safety applications

Safety vs. Availability Trade-off:

1oo2 offers higher reliability but has more false trips.

2oo3 reduces false trips while maintaining high availability.

Cost and Maintenance Considerations:

Higher redundancy increases costs and complexity.

Self-diagnostic and maintenance-friendly designs are preferable.

4. Conclusion

Safety Instrumented Systems (SIS) play a vital role in ensuring the safe operation of chemical plants. They are characterized by high reliability, fast response, independence from control systems, and redundancy-based fault tolerance. Selecting the right redundancy configuration is crucial to balancing safety, availability, and cost. 2oo3 and TMR configurations are widely used in high-SIL applications to enhance reliability and reduce false trips.

For optimal SIS design, chemical plants should adhere to IEC 61508 and IEC 61511 standards, conduct thorough hazard assessments, and implement a robust maintenance strategy to ensure long-term safety and efficiency.