Introduction

Negative pressure in pipelines—defined as internal pressure falling below atmospheric pressure—is a common but often underestimated engineering issue.

In practical operation, negative pressure can lead to serious consequences, including:

Pipeline collapse or deformation

Equipment damage caused by excessive suction forces

Ingress of air or toxic gases into the system

Increased leakage risk and accelerated fatigue failure

Understanding why negative pressure occurs and how to prevent it is essential for the safe design and operation of piping systems.

The causes can be classified according to different types of pipeline systems, as outlined below.

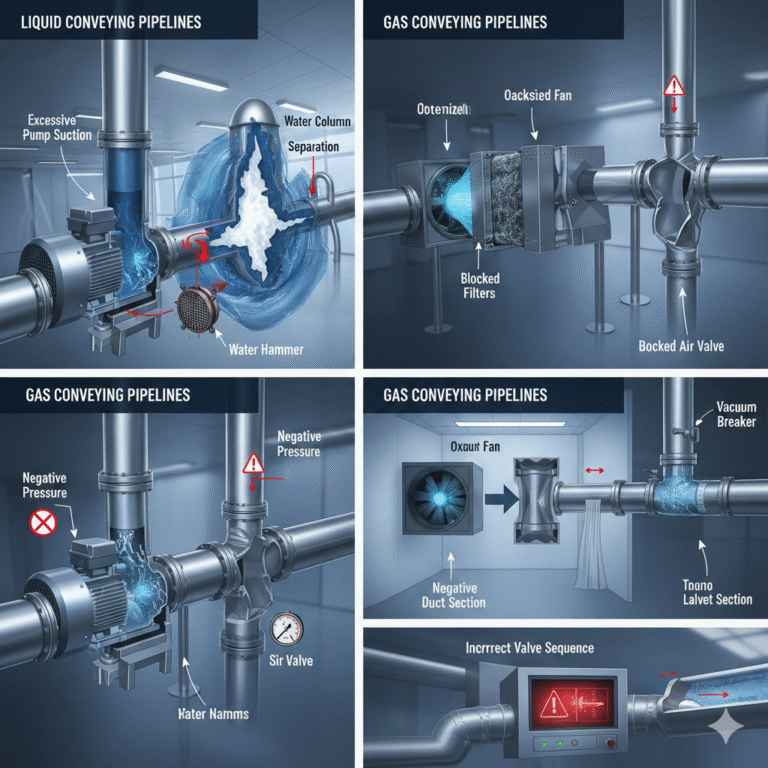

1. Liquid Conveying Pipelines

(Water supply, drainage, chemical process pipelines, etc.)

1.1 Excessive Pump Suction

Oversized or high-head pumps:

If a pump is oversized or operated at excessive speed, its suction capacity may exceed the upstream supply capacity. This can cause negative pressure at the pump inlet.

Inlet blockage or insufficient valve opening:

Partial blockage, clogged strainers, or insufficient valve opening on the suction side restrict inflow. The pump continues extracting liquid, rapidly reducing pressure and potentially creating vacuum conditions.

1.2 Water Column Separation (Transient Vacuum and Water Hammer)

When a pump suddenly stops, the liquid in the pipeline continues moving due to inertia. This creates a low-pressure zone—often near the pump discharge or high points in the system.

If the pressure drops below the vapor pressure of the liquid at operating temperature, vapor cavities form. This phenomenon is known as water column separation.

When flow reverses and these vapor cavities collapse, extremely high-pressure surges occur, generating severe water hammer, which can cause:

Pipe rupture

Flange leakage

Valve and instrument damage

This is one of the most destructive negative-pressure-related failure mechanisms in liquid pipelines.

1.3 Draining and Venting Operations

High-point draining without adequate air intake:

During draining or emptying of elevated pipelines, if air cannot enter due to blocked or undersized air valves, negative pressure will develop at high points.

Siphon interruption:

In siphon systems, exposure of the inlet to air breaks the siphon and may locally generate negative pressure, depending on system configuration.

1.4 Thermal Contraction of Liquid

In pipelines transporting hot liquids (e.g., hot water or thermal oil), isolation of the system without proper expansion or vacuum relief devices can be dangerous.

As the fluid cools, its volume contracts. If no air or makeup fluid is admitted, internal pressure drops significantly, leading to negative pressure and possible pipe collapse.

2. Gas Conveying Pipelines

(Ventilation, HVAC, pneumatic conveying systems, etc.)

2.1 Fan-Induced Suction

Fans inherently create negative pressure at their inlets to draw in gas.

Problems arise when fan capacity exceeds system intake capability, such as:

Blocked filters or louvers

Collapsed duct sections

Excessive system resistance

Under such conditions, negative pressure may rise far beyond design limits.

2.2 System Resistance Imbalance

Mismatch between supply and exhaust airflow:

In enclosed spaces, if exhaust airflow exceeds supply airflow, the entire space—and connected ductwork—will operate under negative pressure. While intentional in some applications (e.g., laboratories), poor control can lead to excessive vacuum levels.

Closure of branch ducts:

When multiple branch ducts are closed while the fan continues running, remaining open branches experience abnormally high negative pressure and airflow velocity.

2.3 Thermal Effects in Gas Pipelines

Hot gases, such as flue gas, gradually cool during long-distance transport.

Cooling reduces gas volume. If the system is sealed and makeup air is not supplied, internal pressure decreases, potentially creating negative pressure conditions.

3. Common Causes Applicable to All Pipeline Systems

3.1 Elevation Changes and High Points

When pipelines pass over high points (profile peaks), fast-moving fluid downstream can exert a “pulling” effect, generating negative pressure at the peak.

This condition is typically mitigated by installing air valves or vacuum breakers at high points.

3.2 Blockage or Excessive Throttling

Any blockage—such as debris, sediment buildup, ice formation, or inadvertent valve closure—creates a pressure drop upstream of the restriction relative to flow direction, potentially causing negative pressure.

3.3 Design Deficiencies

Insufficient venting and vacuum protection:

Air release valves and vacuum breakers act as the “breathing system” of pipelines. Improper selection, incorrect installation location, or poor maintenance can prevent timely air admission, making negative pressure unavoidable during transient events.

Improper pipe sizing:

Excessively small pipe diameters result in high velocities. According to Bernoulli’s principle, increased velocity leads to reduced static pressure, increasing the risk of local negative pressure zones.

3.4 Operational Errors

Common operational causes include:

Incorrect valve operating sequences

Sudden pump start/stop

Rapid system commissioning without proper filling and air removal

Such actions can introduce severe transient pressure fluctuations and instant negative pressure.

Core Principle and Prevention Strategy

The fundamental cause of negative pressure in pipelines is straightforward:

The volume of fluid leaving or being extracted exceeds the volume entering or being replenished.

To prevent negative pressure, both design and operation should focus on:

Proper equipment selection: Match pump and fan capacity to system characteristics

Adequate system “breathing”: Correct placement and maintenance of air valves and vacuum breakers

Control of transient events: Use soft start/stop, variable frequency drives, and surge protection devices

Maintaining flow paths: Regular inspection and cleaning to prevent blockage