Temperature transmitter signal fluctuations can arise from various factors, including sensor issues, signal transmission disturbances, transmitter faults, environmental influences, grounding issues, and software or configuration problems. A systematic analysis is required to accurately identify and resolve these issues.

1. Sensor Issues

Poor Contact: Loose, oxidized, or corroded terminals at thermocouple or RTD connections can cause intermittent signals. Inspect and tighten terminals regularly.

Sensor Damage: Internal wire breaks, insulation degradation, or aging sensors can result in sudden signal jumps. Test the sensor resistance or voltage output to verify integrity.

Cold Junction Compensation Errors (Thermocouples only): Failure in compensation circuits or fluctuations in reference junction temperature lead to erratic signals. Verify cold junction compensation accuracy periodically.

Incorrect Installation: Sensors partially inserted into media or located in areas of steep temperature gradients may lead to measurement instability. Ensure full immersion of sensors and proper installation.

2. Signal Transmission Interference

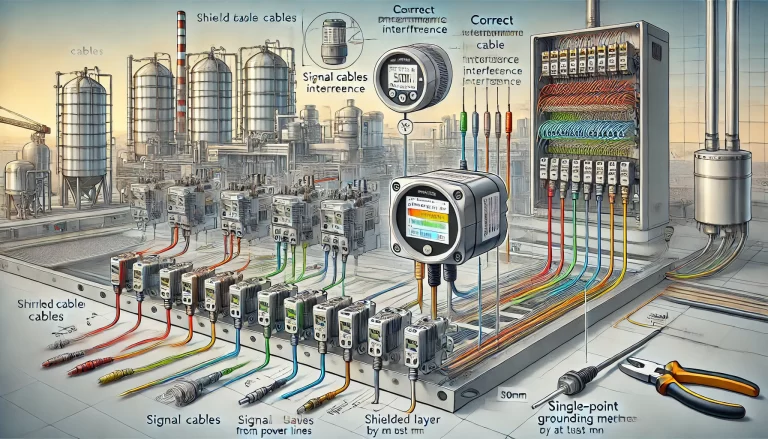

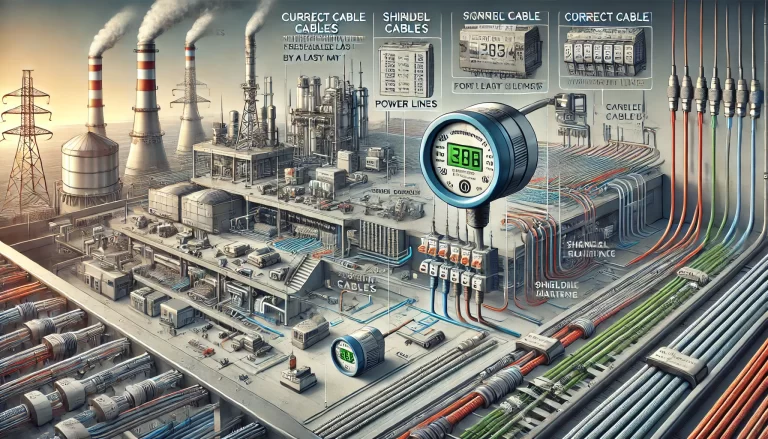

Cable Damage: Damaged cable insulation, broken shielding, or poor grounding may introduce electromagnetic interference (EMI), particularly from sources like frequency converters, motors, or wireless equipment.

Long-Distance Transmission: Using unshielded cables or neglecting signal isolators can result in noise accumulation. Employ shielded cables and isolation modules for noise reduction.

Power Supply Interference: Voltage fluctuations, power surges, or common-mode interference (e.g., power cables routed parallel to signal cables) can disrupt signals. Separate signal cables from power lines and use stabilized power supplies.

3. Transmitter Faults

Component Aging: Aging capacitors, resistors, solder joint degradation, or components with poor thermal stability can induce unstable signals. Inspect transmitter components periodically.

Power Supply Issues: Failures in internal voltage regulation circuits or defective filtering capacitors cause output fluctuations. Use regulated and filtered power sources for testing.

Calibration Errors: Improper zero-point, span, or linearity settings, or calibration drift over time, may result in unstable transmitter outputs. Regularly verify and recalibrate transmitters.

4. Environmental Influences

Extreme Temperature Fluctuations: Exposure of transmitters or sensors to rapidly alternating high and low temperatures outside their operating ranges can cause instability. Install equipment in controlled environments when possible.

Mechanical Vibration: Excessive vibration may loosen internal components or terminals, resulting in unstable signals. Securely mount equipment away from vibrating machinery.

Humidity or Corrosive Atmosphere: Moisture ingress or exposure to corrosive gases can damage circuitry and sensors. Employ suitable environmental protections and enclosures.

5. Grounding Issues

Ground Loops: Multiple grounding points can create ground loops, introducing unwanted interference currents. Implement a single-point grounding scheme to eliminate this issue.

Poor Grounding: High grounding resistance diminishes shielding effectiveness. Regularly measure and ensure grounding resistance is below 1Ω.

6. Software and Configuration Problems

Incorrect Filtering Settings: Inadequate filter settings or short filtering time constants may fail to smooth signal fluctuations. Adjust filtering parameters appropriately for process requirements.

Communication Issues (Smart Transmitters): Protocol conflicts, configuration errors, or firmware bugs can cause erratic outputs. Update firmware regularly and verify configuration settings.

Range Mismatch: A mismatch between transmitter range settings and sensor type or actual process conditions leads to inaccurate or fluctuating outputs. Confirm correct range and configuration.

7. Process-Related Causes

Actual Temperature Variability: Rapid temperature changes within process vessels or turbulent fluid flow may cause real fluctuations at the measurement point. Adjust process conditions or sensor placement as necessary.

Incorrect Sensor Positioning: Installing sensors in areas with sudden flow or temperature changes, such as near heating or cooling sources, affects measurement accuracy. Relocate sensors to more stable positions.

Recommended Troubleshooting Steps:

Wiring Inspection: Tighten terminals, test sensor resistance or voltage outputs to rule out wiring faults.

Interference Isolation: Disconnect transmitters, simulate inputs with signal generators, and observe output stability.

Power Supply Testing: Monitor power supply voltage stability using regulated power supplies.

Grounding Verification: Ensure single-point grounding and measure grounding resistance, maintaining it below 1Ω.

Environmental Evaluation: Check that operating conditions (temperature, humidity, vibration) align with device specifications.

Parameter Checks: Review and confirm transmitter range, filtering parameters, and calibration records.

Component Substitution Test: Replace suspect sensors or transmitters temporarily to determine if the issue persists or shifts with equipment.

Through structured and systematic troubleshooting, you can effectively pinpoint and resolve the root cause of temperature transmitter signal fluctuations. For more complex interference scenarios, utilize oscilloscopes or spectrum analyzers to accurately identify and diagnose abnormal signal characteristics.