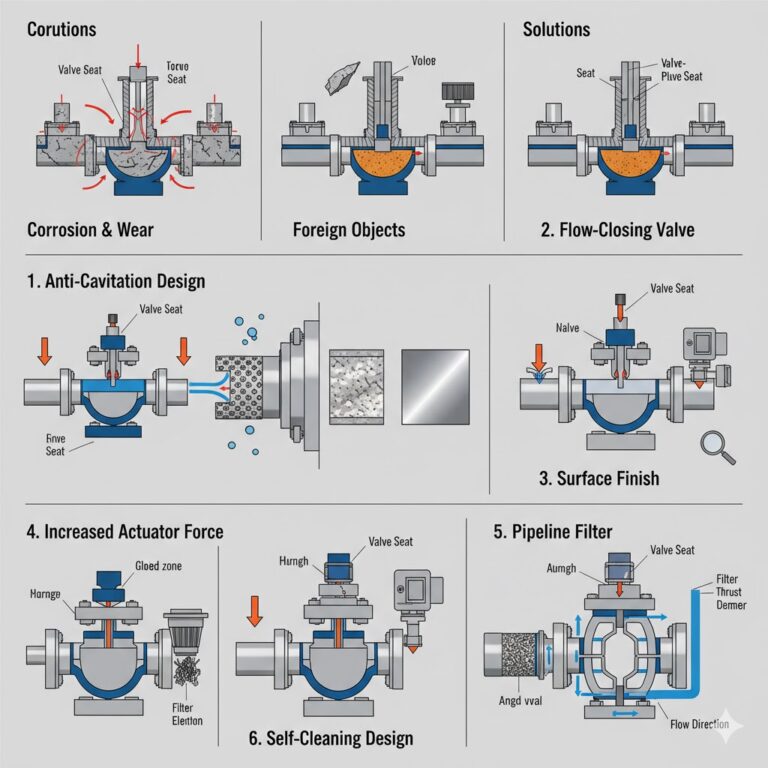

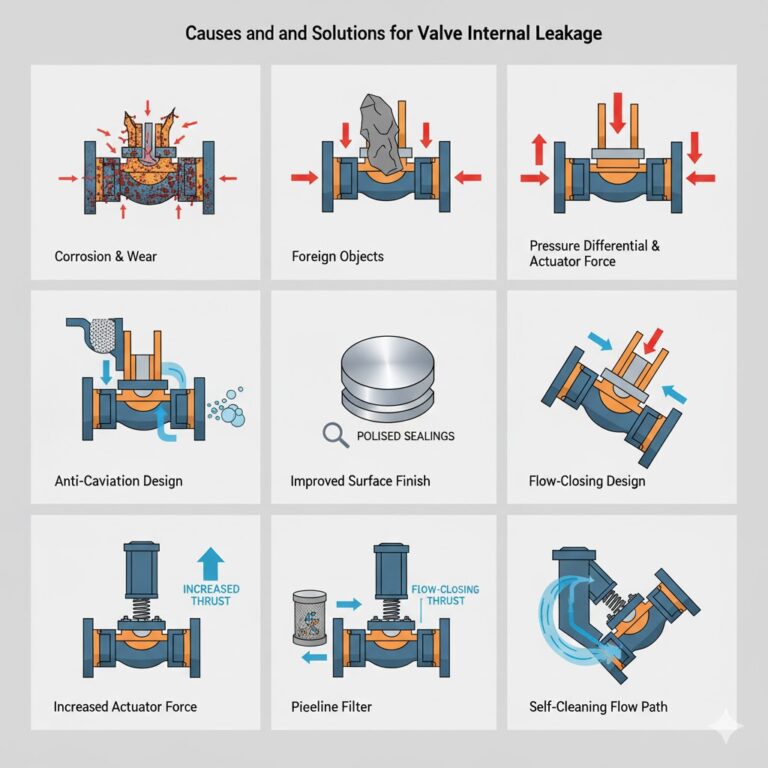

1. Causes of Valve Internal Leakage:

Corrosion and Wear of Valve Core or Valve Seat: Over time, wear and corrosion can compromise the sealing performance of the valve, leading to internal leakage.

Corrosion of the External Thread of the Valve Seat: Corrosion can damage the valve seat’s external threads, affecting its sealing capability.

Large Pressure Differential: When the pressure differential across the valve is too high, the actuator may lack sufficient output force, leading to internal leakage.

Foreign Objects in the Valve Body: Debris or contaminants inside the valve can prevent proper sealing, causing leaks.

2. Solutions to Prevent and Address Valve Internal Leakage:

2.1 Choose the Right Valve Components

Select appropriate valve components such as valve cores, valve seats, and valve stems. For demanding applications, materials like 1Cr18Ni9Ti or other stainless steels are recommended. In conditions with severe flashing or cavitation, surface hardening treatments like cobalt-chromium-tungsten hard alloys can be applied. For highly corrosive environments, materials such as nickel alloys, titanium, or non-metallic materials are ideal. Common nickel alloys include Monel (nickel-copper alloy, suitable for alkalis and hydrofluoric acid), Hastelloy B (nickel-molybdenum alloy, resistant to acids like hydrochloric, sulfuric, and nitric acids), and Hastelloy C (nickel-molybdenum-chromium alloy, ideal for low concentrations of hydrochloric and nitric acid).

2.2 Reduce Cavitation and Erosion Damage

To reduce cavitation wear, consider the following methods:

Maintain Sufficient Downstream Pressure: Ensure downstream pressure exceeds the liquid’s vapor pressure to prevent bubble formation in low-pressure zones. Typically, anti-cavitation throttle plates (porous sieve plates) are installed at the valve outlet, with hole size and quantity adjusted based on the differential pressure.

Use Flow-Closing Valves: For high-pressure angular valves, use sharp-edged valve seat holes to direct the flow away from the valve body. This minimizes cavitation damage by crushing bubbles in the flow rather than allowing them to expand and damage the valve body.

Use Two Valves in Series: By splitting the pressure drop across two valves, the first valve can handle a larger pressure drop, which helps reduce cavitation in the second valve.

2.3 Improve Seal Surface Finish

Polishing the sealing surfaces to enhance smoothness can help reduce or eliminate the sealing gap, improving the valve’s sealing performance.

2.4 Convert Flow-Open Valves to Flow-Closing Valves

Flow-closing valves naturally create a closing force on the valve core, ensuring better sealing performance compared to flow-opening valves.

2.5 Increase Actuator Output Force

Increasing the actuator’s output force is a common solution to improve sealing. This can be achieved by adjusting the spring range, using lower stiffness springs, adding positioners, increasing the air source pressure, or switching to actuators with higher thrust.

2.6 Clean the Valve and Remove Debris

For small-bore control valves, especially those for low flow rates, consider installing pipeline filters before the valve to prevent debris buildup, which can impair sealing.

2.7 Switch to Alternative Valve Types

For valves with poor self-cleaning properties (such as direct-acting valves with a dead zone in the flow cavity), consider switching to valves with a window-type throttling area or an angular valve with an “L” shaped flow path, which has better self-cleaning performance.