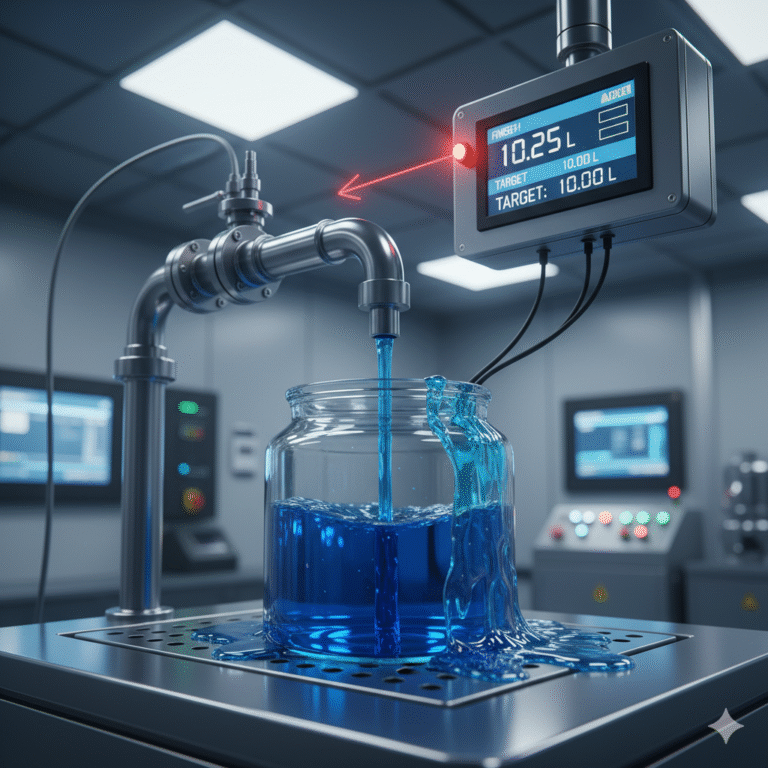

Overloading phenomenon is a common issue in the batch material dispensing control process. Specifically, when the total dispensing amount reaches the preset value, the controller immediately sends a signal to close the valve. However, due to system lag and inertia, some fluid continues to flow towards the receiving end, causing the final dispensing amount to exceed the preset value.

Causes of Overloading:

Actuator Response Lag: After the controller sends a signal to close the valve, the valve does not immediately close due to inherent delay. This delay period, referred to as lag time, causes fluid to continue flowing, leading to an over-dispensed amount. Lag time includes both relay response delay and the valve’s own response delay.

Relation Between Lag Time and Flow Rate: The overloading value is roughly proportional to the lag time t and the instantaneous flow rate qv, expressed as t×qv. The duration of lag time is influenced by the valve model and diameter. Typically, smaller valves have a lag time of a few milliseconds, while larger valves exhibit longer lag times.

Cumulative Error: The error caused by lag time can be clearly observed in the controller’s accumulated value display. This cumulative error reflects the overloading caused by delayed valve actions.

Solutions:

Set a Preload Value: The simplest solution is to set a preload value

in the controller’s “advance amount” window. This means that when the actual dispensing amount

is less than the preset amount

by

(i.e.,

), the controller will send a signal to close the valve. By measuring the average overloading value through multiple tests, you can set this preload value

into the instrument for long-term use.

Switch to Large and Small Valve Control: Another method to improve accuracy is to use a system that controls both a large and small valve. Each valve has a separate preload setting. When the preload for the large valve is reached, it closes first, and the small valve continues dispensing. When the preload for the small valve is reached, dispensing is fully stopped. Since the instantaneous flow rate at the end of dispensing is only 1/20 to 1/10 of the large valve’s flow, this method increases the control accuracy by 10 to 20 times.

By applying these methods, the overloading caused by actuator response delay can be significantly reduced, and the accuracy and stability of batch material dispensing control can be greatly improved.