In industrial environments, the integrity of instrumentation cable trays is essential for ensuring the safety and stability of control systems. A common but often overlooked safety hazard is the falling off of cable tray covers. This issue can lead to potential injury, equipment damage, or service disruptions. This article analyzes the main causes of cable tray cover detachment and provides practical preventive measures.

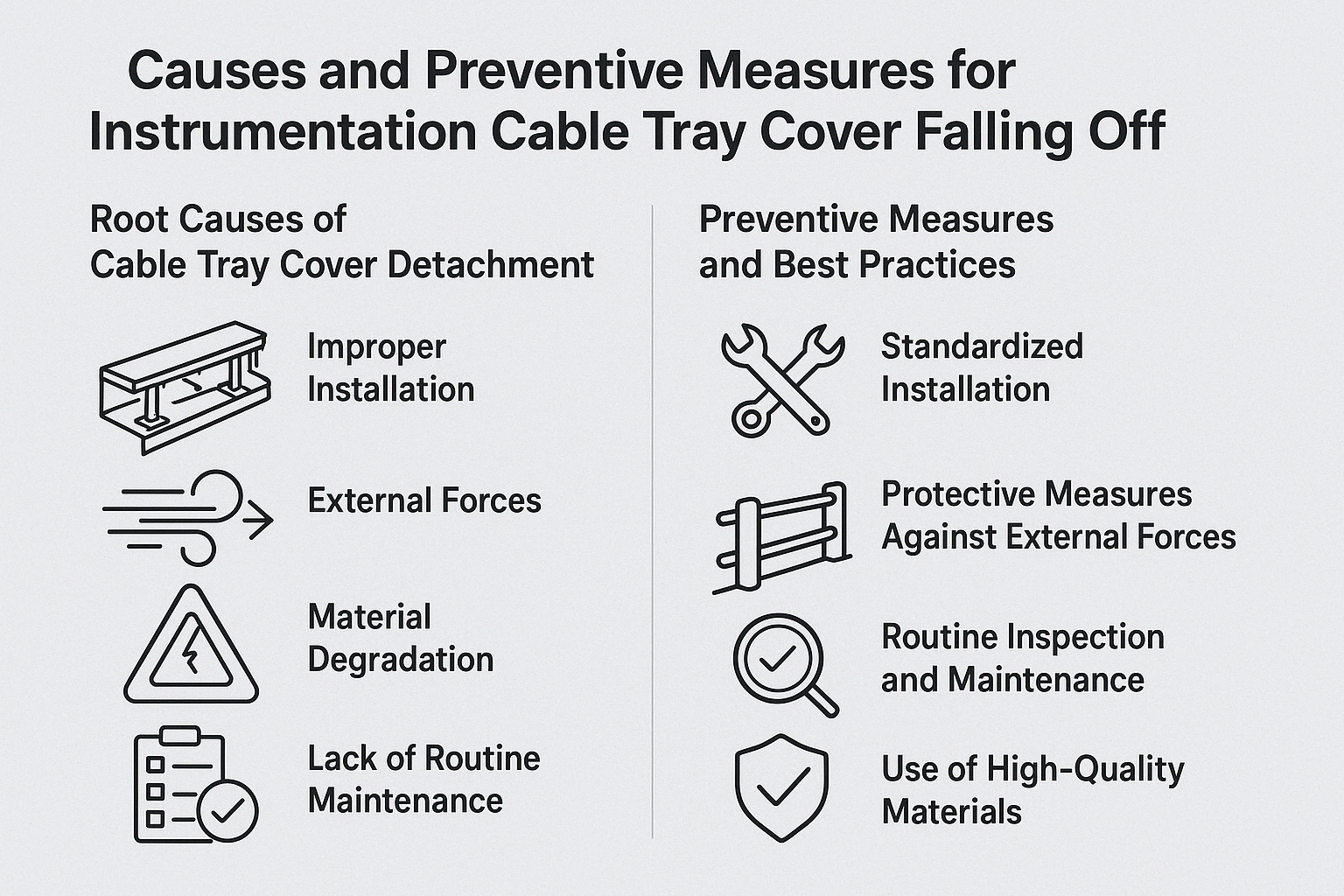

1. Root Causes of Cable Tray Cover Detachment

1.1 Improper Installation

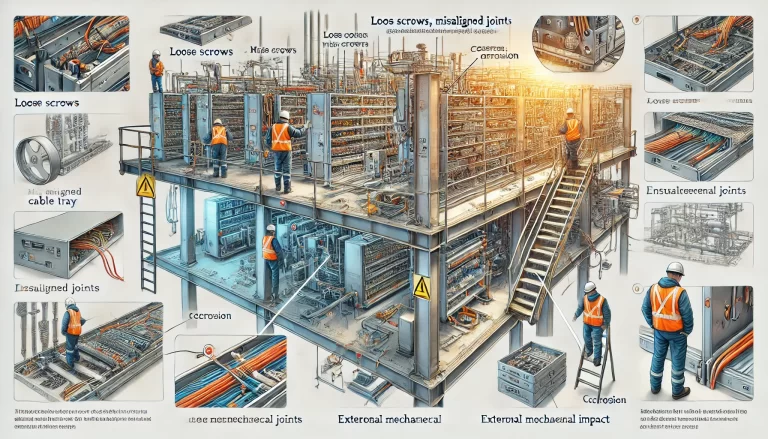

Loose or Insecure Fastening: If covers are not properly snapped into place or if fastening screws are inadequately tightened during installation, the cover may not stay secure.

Uneven Joints: Misalignment at tray connection points can create gaps or unstable surfaces, making it difficult for the cover to seat properly and increasing the risk of detachment during operation.

1.2 External Forces

Mechanical Impact: Human contact, vehicular bumps, or interference from other construction activities can exert force on the cable tray, dislodging inadequately secured covers.

Wind Load in Outdoor Settings: For outdoor installations, strong wind gusts can lift and detach poorly fixed or lightweight covers.

1.3 Material Degradation

Aging and Brittleness: Prolonged exposure to UV radiation, humidity, and temperature changes can cause materials (especially plastic or low-grade metal) to become brittle or deformed, reducing their mechanical strength.

Corrosion: In coastal or chemically aggressive environments, corrosion can weaken metal components, leading to the loosening or failure of the fixing mechanism.

1.4 Lack of Routine Maintenance

Undetected Wear and Tear: Without regular inspection, early signs of damage—such as loosened fasteners, bent edges, or cracked covers—may go unnoticed. These hidden risks can accumulate and result in sudden detachment under normal load or stress.

2. Preventive Measures and Best Practices

2.1 Standardized Installation

Follow Manufacturer Guidelines: Ensure covers are installed according to specified torque requirements and that all joints are aligned.

Tighten Fasteners Properly: Use proper tools to ensure all bolts and screws are firmly secured.

Installation Quality Check: Inspect the entire system after installation to verify that all covers are tightly fitted and flush with the tray body.

2.2 Protective Measures Against External Forces

Barrier Installation: For cable trays located near roads, walkways, or heavy-traffic areas, install protective barriers or warning signage to reduce the chance of mechanical impact.

Wind-Resistant Fixing Accessories: In outdoor installations, use wind clips, locking mechanisms, or reinforced clamps to prevent dislodging under high wind conditions.

2.3 Routine Inspection and Maintenance

Establish a Maintenance Schedule: Assign personnel to inspect cable tray systems at regular intervals—e.g., quarterly or biannually.

Use of UAVs for High Areas: Employ drones to inspect elevated trays where manual inspection is challenging or risky.

Timely Replacement: Replace any aging, deformed, or corroded covers and fasteners during inspections to prevent future detachment.

2.4 Use of High-Quality Materials

Material Selection Criteria: Choose covers made from UV-resistant plastics or anti-corrosive stainless steel for long-term reliability.

Environmental Compatibility: Select materials based on the surrounding environment (e.g., anti-corrosion for coastal plants or flame-retardant materials for petrochemical facilities).

3. Conclusion

The falling off of cable tray covers is a multifactorial problem involving installation quality, environmental conditions, material durability, and maintenance diligence. By addressing each of these areas through structured engineering practices and routine oversight, the risk of such failures can be greatly reduced. Implementing these preventive measures not only enhances operational safety but also extends the life cycle of the cable management infrastructure.