Abstract

This case study describes a packaging system failure in a polyacrylamide production line, triggered by an accidental disconnection of a weighing sensor during routine cleaning. The incident highlights the importance of preventive maintenance and operational discipline in industrial environments. Root cause analysis, corrective actions, and preventive measures are discussed to provide guidance for similar scenarios.

1. Background

The packaging process of the polyacrylamide unit involves multiple stages: dissolution, polymerization, pre-grinding, granulation, hydrolysis, drying, fine grinding, sieving, and finally, weighing and packaging.

The weighing and packaging system consists of:

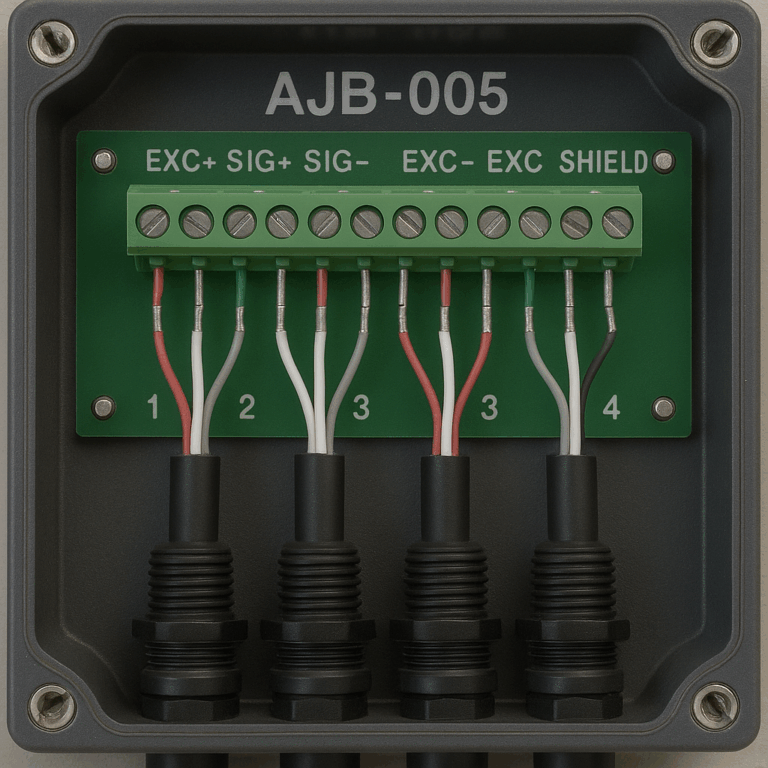

Four weighing modules connected to the silo.

AJB-005 junction box integrating load cell signals.

AD-4401 weighing indicator communicating with the PLC via RS-485.

The PLC controls nine solenoid valves and two motors for material handling.

2. Incident Description

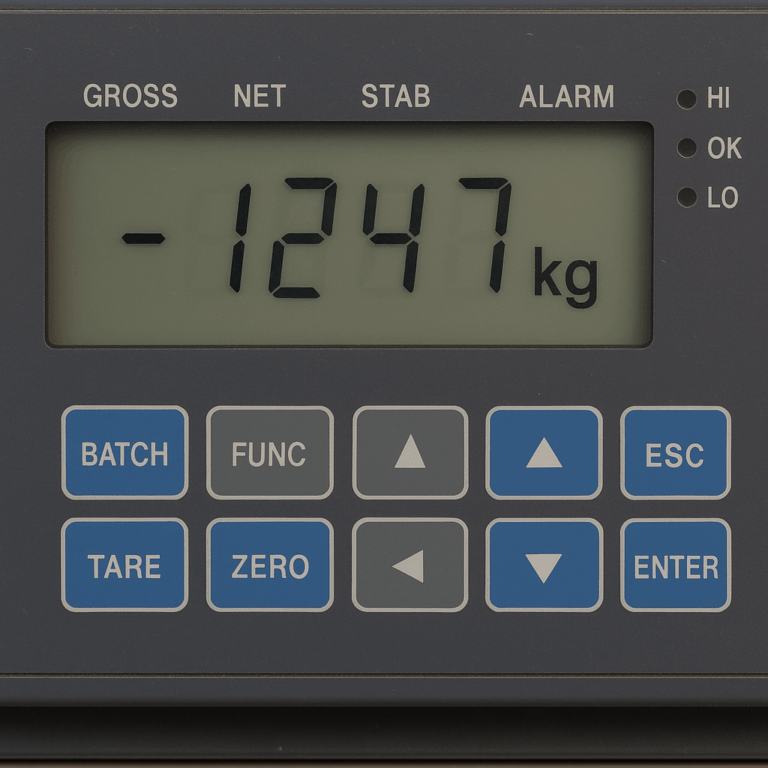

During routine cleaning, an operator removed residual powder from the load cells. When production resumed, the packaging controller suddenly displayed a negative weight of –1247 kg, the program was interrupted, and no alarm was triggered.

Further inspection revealed:

The signal cable of load cell No. 3 was loosely connected due to accidental contact during cleaning.

Preventive maintenance schedules did not include detailed checks of the weighing modules and cabling.

3. Root Cause Analysis

Direct cause: Loose connection at the signal terminal of load cell No. 3.

Indirect cause: Lack of routine inspection and maintenance coverage for weighing equipment.

Contributing factors:

Cleaning procedure did not specify “no contact with wiring terminals.”

Connection terminals were not mechanically reinforced against incidental touch.

4. Corrective Actions

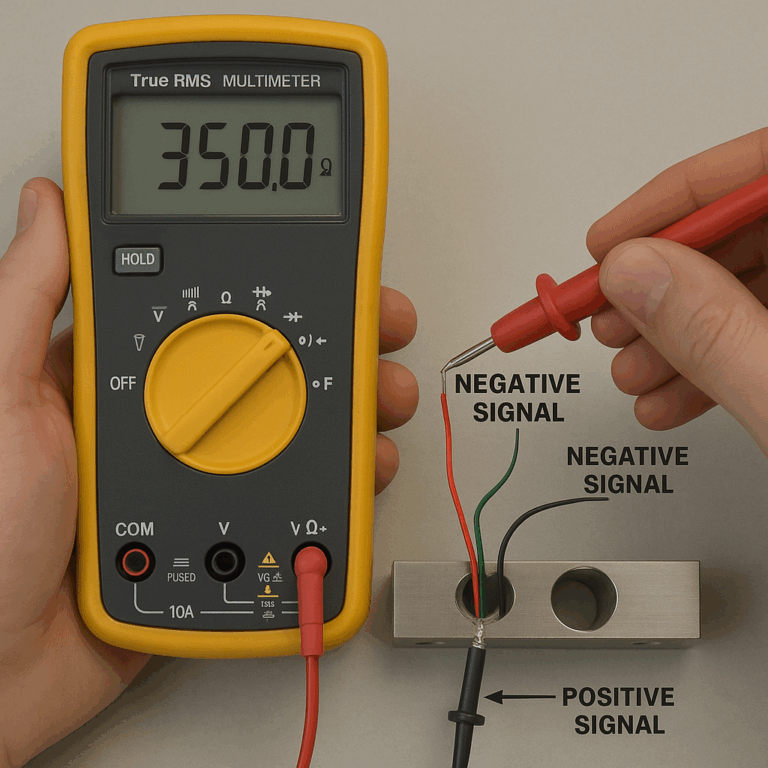

Resistance between positive and negative signal leads of load cell No. 3 was measured: 790 Ω (abnormal, expected 350 ± 2 Ω).

After reconnecting the cable, resistance returned to normal, and weight reading stabilized at –750 kg (tare condition).

Packaging program was restarted, and system operation recovered.

5. Preventive Measures

To prevent recurrence:

Operational discipline: Cleaning and inspection staff must avoid contact with sensor terminals and wiring.

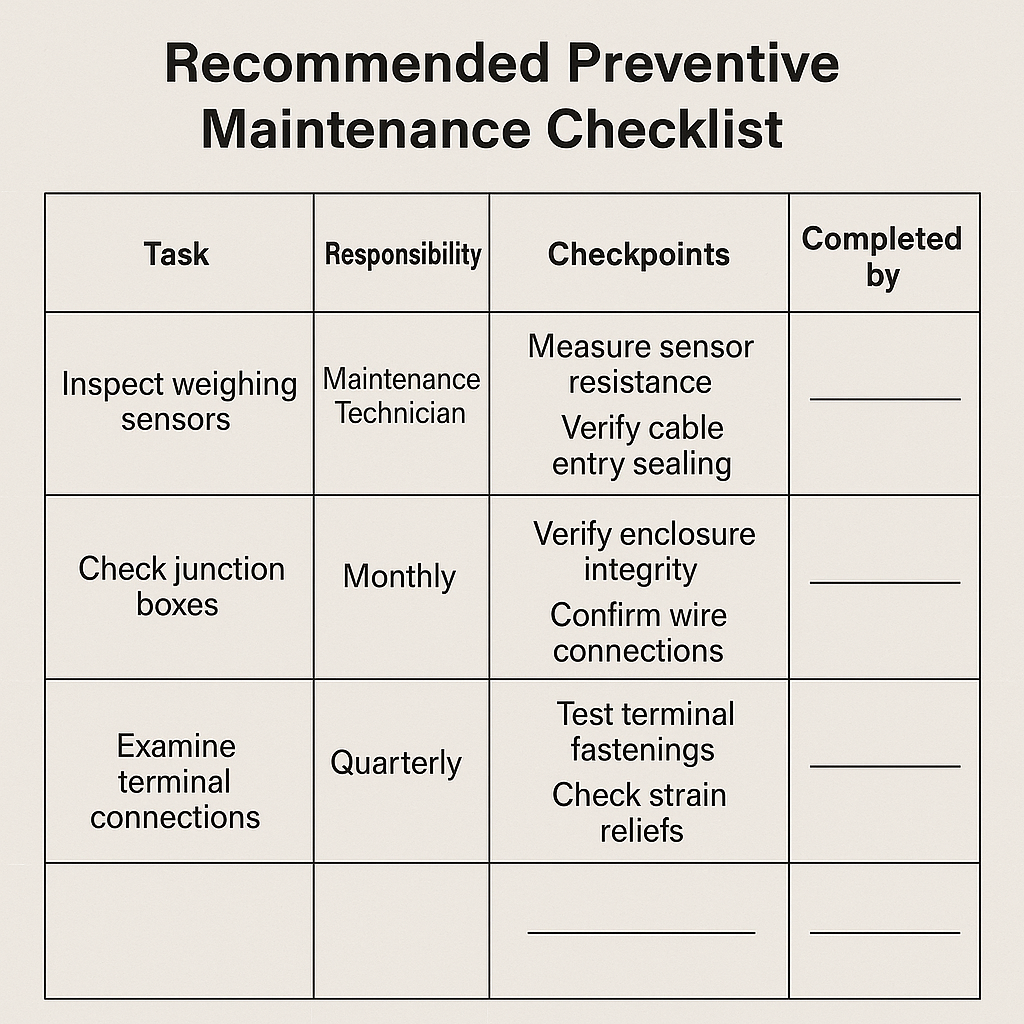

Regular maintenance: Include all weighing sensors, junction boxes, and terminal connections in the preventive maintenance checklist.

Inspection method:

Verify sensor resistance using a multimeter.

Inspect sealing of cable entries and mechanical fastening of terminals.

Documentation: Record maintenance tasks in log sheets and require supervisor sign-off.

Design improvements:

Provide protective covers for load cell terminals.

Apply proper strain relief to prevent wire loosening.

6. Lessons Learned

Seemingly minor actions—such as dust removal—can inadvertently lead to major production interruptions when not performed under controlled procedures. This case underscores that:

Minor misoperations can trigger critical failures.

Preventive maintenance programs must cover all auxiliary equipment.

Clear operating procedures and training are essential to minimize human-factor risks.